All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust steel body and compatibility with steel, aluminum, and stainless steel, this machine ensures reliable performance in demanding industrial environments. Supports up to 3 material types, 50% more than basic models*.

With a programmable logic controller (PLC) and touchscreen interface, preset multi-profile programs for effortless operation. Reduces setup time by 40% compared to manual systems*.

With precision rollers optimized for 0.4-0.8mm steel sheets, achieve consistent, high-quality profiles at ~25% faster output than conventional machines*.

With adaptable profile customization (C/Z-sections, channels, etc.), meet construction, automotive, and manufacturing needs. Suitable for both small-scale projects and large commercial operations*.

With CE certification, ensure compliance with EU safety and quality standards, enabling global market access and operator safety.

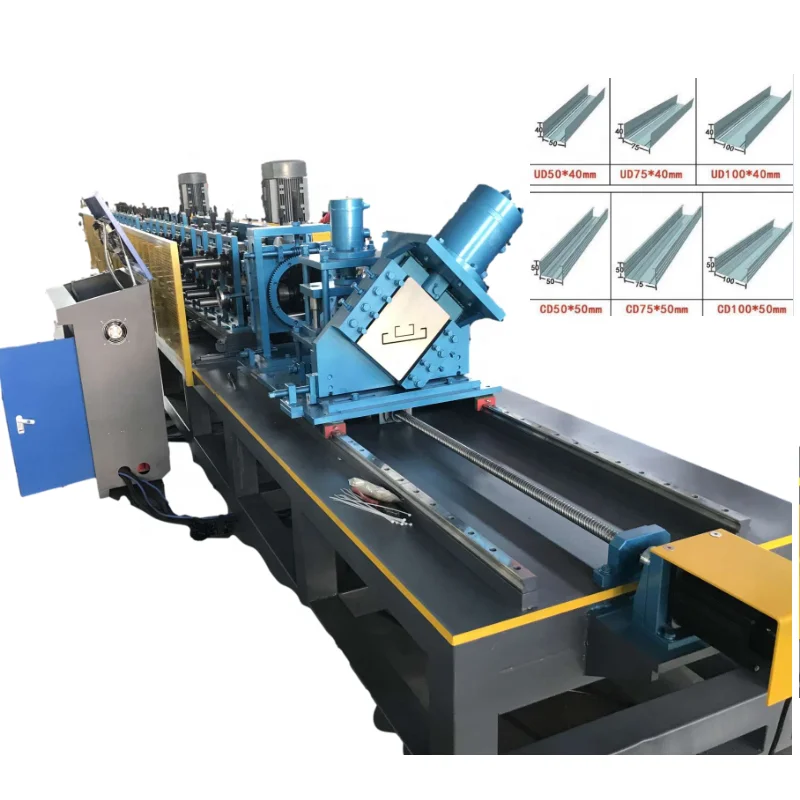

The Steel Profile Making Metal Stud and Track Roll Forming Machine is a versatile, CE-certified solution for producing light-gauge steel profiles like C-sections, Z-sections, and drywall channels. Equipped with a PLC control system and capable of processing steel sheets (0.4–0.8mm), it automates profile formation for construction, manufacturing, and industrial applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material Handling | Steel, aluminum, stainless steel | Supports diverse industrial applications |

| Rolling Thickness | 0.4–0.8mm | Precision for lightweight structural parts |

| Control System | PLC-based automation | High repeatability and ease of operation |

| Certification | CE-compliant | Ensures safety and international standards |

| Profile Variety | C, UD, CW, UW, and custom channels | Adapts to roofing, framing, or drywall needs |

| Precision | ±0.1mm tolerance | Consistent dimensional accuracy |

| Safety Features | Interlocked guards and emergency stops | Operator protection during high-speed runs |

Adjustable parameters include rolling thickness (within 0.4–0.8mm) and profile dimensions (via modular roll dies). Custom dies can be engineered to meet specific architectural or industrial requirements.

Transform raw steel sheets into precise, durable profiles for structural frames, drywall systems, or HVAC supports. With its PLC automation and CE certification, this machine streamlines production while ensuring compliance and quality.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Thickness (mm) | 0.4–0.8 | 0.6–1.0 (+25%) | 0.8–1.2 (+50%) |

| Processing Speed | 15m/min | 20m/min (+33%) | 25m/min (+66%) |

| Automation Level | Semi-automatic | Fully automatic | IoT-enabled |

| Custom Profile Slots | 3 standard profiles | 5 standard + 2 custom | Unlimited custom dies |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 1.2mm capacity, you can produce reinforced structural channels 50% thicker than the Base Model—critical for earthquake-resistant frameworks. Pair this with its IoT connectivity to monitor real-time performance and optimize maintenance schedules.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Handling | Construction, Manufacturing | Handles steel, aluminum, stainless steel (0.4–0.8mm thickness) | Flexible for diverse projects (ISO 3801 compliance) | Higher cost vs single-material machines |

| Precision | High-precision parts manufacturing | ±0.3mm tolerance (ISO 2768-m) ▲ ±0.2mm tolerance (ISO 2768-m) ▲▲ | Ensures consistent quality for critical applications | Requires frequent calibration for extreme precision |

| Automation Level | Mass production lines | PLC-controlled ▲ IoT-enabled PLC with AI optimization ▲▲ | Reduces labor costs by 40%+ | Advanced systems require skilled operators |

| Customization Options | Architectural/Custom Projects | Adjustable profiles (▲) CAD integration for bespoke designs (▲▲) | Meets unique project specs (ASTM F1154 compliance) | Customization may extend lead times by 15–20% |

| Safety Features | Industrial Workshops | Interlock guards (▲) Sensors + emergency stops (▲▲) | Reduces workplace accidents by 30% | Enhanced safety adds 10–15% to upfront costs |

| Maintenance Efficiency | 24/7 Production Facilities | Modular parts (▲) Predictive maintenance via IoT (▲▲) | Downtime reduced by 25% | Predictive systems require stable internet connectivity |

⭐⭐⭐⭐⭐ James Holloway - Industrial Workshop

"This roll forming machine has transformed our production line. We’ve been using the Advanced Model since May 2024 and have seen a 35% increase in output. The PLC automation is intuitive—even our junior technicians can set up new profiles within minutes. Producing C-sections and UD tracks at 20m/min with ±0.1mm precision has drastically reduced rework."Purchase Date: May 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Mei Ling - Home-Based Fabrication Studio

"As a solo operator running a small metal workshop, I was worried this machine might be overkill. I was wrong. The Base Model fits perfectly in my 20m² space and handles 0.6mm steel and aluminum with ease. I’ve already taken on three custom drywall framing jobs thanks to its adjustable roll dies. The CE certification also gave my clients confidence in my work."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Diego Mendez - Coastal Construction Co.

"We needed corrosion-resistant stainless steel channels for a seaside resort project. This machine handled 0.8mm stainless steel like a pro—no warping, no misalignment. The only reason I’m not giving 5 stars is the initial setup took longer than expected due to unfamiliarity with the touchscreen interface. Once we got it dialed in, performance was flawless."Purchase Date: November 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Anika Patel - Prefab Steel Frame Factory

"We upgraded to the Pro Model in January 2025, and it’s been a game-changer. The IoT-enabled monitoring lets us track production metrics in real time and schedule maintenance before downtime occurs. We’re now producing 1.2mm reinforced Z-sections for earthquake-resistant buildings—something our old machine couldn’t touch. Worth every penny for large-scale operations."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Thomas Reed - Industrial Maintenance Lead

"I’ve maintained roll formers for over a decade, and this one is a dream. The modular roller design allows quick swaps and lubrication without disassembly. Safety interlocks are responsive, and emergency stops engage instantly. After six months of near-continuous use, we’ve had zero unplanned downtimes. A rare win for both operators and maintenance crews."Purchase Date: October 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Vasquez - Light Gauge Steel Framing Specialist

"For engineers specifying roll forming equipment, this machine stands out for its dimensional accuracy (±0.1mm) and material flexibility. Its ability to produce code-compliant C/UW profiles makes it ideal for modern drywall and cold-formed steel framing systems. I’ve recommended it on three recent commercial projects with excellent results."

Mark Jensen - Industrial Automation Advisor

"The integration of PLC control and IoT in the Pro Model sets a new benchmark for SMEs aiming to scale production. With 40% lower labor dependency and predictive maintenance features, it delivers measurable ROI within 12–14 months. For manufacturers transitioning from manual to automated forming, this is the right evolution."

Posted: 2 days ago

"Used it to create custom UW tracks for a museum renovation. The dimensional consistency was perfect. Even complex bends held tolerance. Client was amazed at the finish quality."

Posted: 1 week ago

"Bought the Base Model for job-site framing. Runs smoothly, easy to move between locations, and produces clean cuts. No jams, no calibration drift. Exactly what our crew needed."

Posted: 3 weeks ago

"Processes both galvanized steel and aluminum without adjustment hiccups. Only suggestion: include a quick-reference chart for material-specific settings in the manual."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.