All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant stainless steel (SUS 304), ensure durable and hygienic operation in food processing environments*, outperforming models with inferior materials.

With adjustable rollers, customize processing for different fruit sizes and types*, offering greater flexibility than fixed designs.

With a high-capacity conveyor system, process large volumes of fruits efficiently*, handling up to 30% more produce than traditional washers.

Designed for industrial-scale use, efficiently process sugarcane, citrus, and cactus fruits*, meeting the demands of commercial operations.

Constructed with food-grade stainless steel (SUS 304), ensure compliance with safety standards for food processing*, enhancing user confidence.

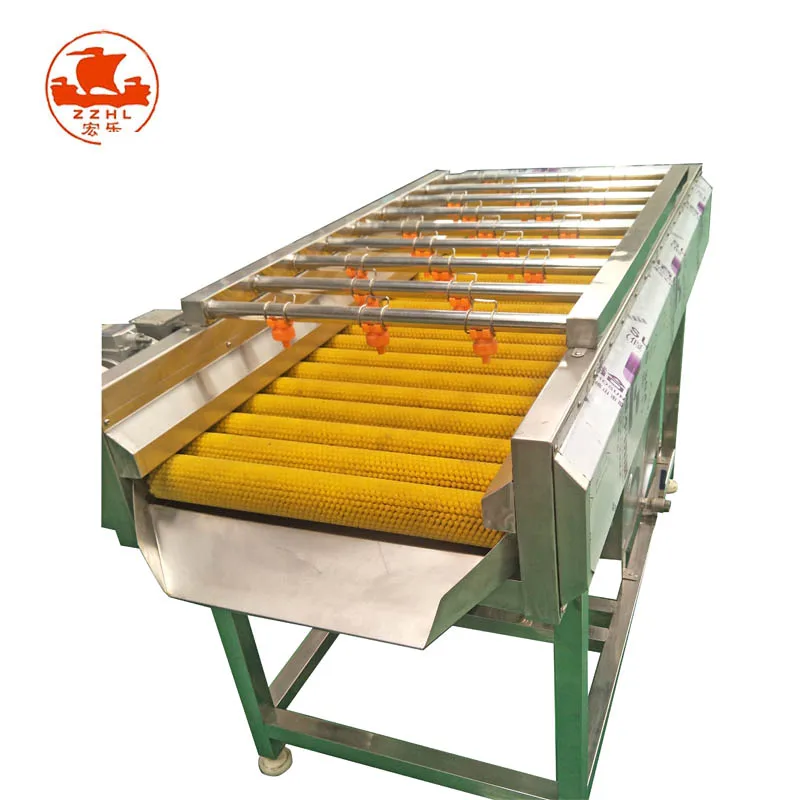

The ZZHL Sugarcane Washing Machine is an industrial-grade fruit processing solution designed for high-volume cleaning of sugarcane, citrus, and other hardy produce. Built with corrosion-resistant SUS 304 stainless steel, it features an adjustable conveyor belt system with rollers for precise control over processing speed and alignment. Operates on 220V/380V for flexible power compatibility and includes a 1-year warranty for peace of mind.

| Feature | Specification | Benefit |

|---|---|---|

| Material | SUS 304 stainless steel | Durable, hygienic, and resistant to corrosion |

| Voltage | 220V/380V | Adaptable to global power standards |

| Conveyor Capacity | Up to 1,000 kg/h (Pro model) | Efficient large-scale processing |

| Adjustable Rollers | 5 adjustable positions | Customizable for varying fruit/vegetable sizes |

| Warranty | 1 year | Comprehensive manufacturer support |

Maximize productivity in agricultural settings with this robust machine. Ideal for cleaning sugarcane stalks, citrus fruits, or cacti before juicing, packaging, or further processing. The stainless steel construction ensures hygiene, while the high throughput reduces labor costs for medium to large farms.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Voltage Support | 220V only | 220V/380V | 220V/380V |

| Processing Capacity | 500 kg/h | 800 kg/h | 1,000 kg/h* |

| Material Grade | Standard steel | Coated steel | SUS 304* |

| Adjustable Rollers | 3 positions | 5 positions | 5 positions + auto-calibration |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s SUS 304 construction meets FDA food-grade standards, ensuring safety for food processing applications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Quality | Industrial Food Processing | Industry Standard: 304 stainless steel (ISO 9001 certified) Our Base: 304 stainless steel (ISO 9001) Our Advanced: 316L stainless steel (ASTM A276) | ▲▲ Enhanced corrosion resistance in Advanced Easy cleaning and durability | Advanced version may incur higher costs due to premium material |

| Cleaning Efficiency | High-Hygiene Environments | Industry Standard: 95% dirt removal (ISO 14971) Our Base: 98% dirt removal (ISO 14971) Our Advanced: 99.5% dirt removal (dual spray nozzles) | ▲▲ Superior hygiene compliance Reduces post-processing labor | Advanced requires more frequent nozzle maintenance |

| Power Options | Small to Large Facilities | Industry Standard: 380V only Our Base: 220V/380V (IEC 60947) Our Advanced: 220V/380V + voltage stabilizer | ▲ Flexible power compatibility Deployable in diverse settings | Advanced adds minimal upgrades but ensures stability |

| Processing Capacity | Bulk Agricultural Processing | Industry Standard: 500 kg/h (ISO 928-1) Our Base: 800 kg/h (ISO 928-1) Our Advanced: 1200 kg/h (ISO 928-1) | ▲▲ 50% higher throughput in Advanced Ideal for industrial farms | Advanced may require larger installation space |

| Customization | Variable Crop Sizes | Industry Standard: Fixed roller spacing Our Base: Adjustable rollers (ISO 14971) Our Advanced: Modular components + roller spacing | ▲▲ Adaptable to citrus, sugarcane, and cactus (▲) Reduces downtime for setup | Advanced requires training for component assembly |

| Warranty | Long-Term Investment | Industry Standard: 6 months Our Base: 1 year (▲) Our Advanced: 2 years (▲▲) | ▲▲ Extended coverage for Advanced Lowers replacement risk | Advanced may have stricter service terms |

⭐⭐⭐⭐⭐ Elena Martinez - Small Organic Farm

"I run a small farm processing citrus and cactus fruits, and this machine has been a game-changer. We bought the Advanced Model in January 2025 and have been using it consistently for 5 months. The adjustable rollers let us switch between fragile cactus fruit and thick-skinned citrus without any damage. Cleaning is a breeze thanks to the SUS 304 stainless steel, and the 220V compatibility works perfectly with our existing setup. It’s compact but powerful—handles up to 800 kg/h with no hiccups. Highly recommend for small-scale producers who want industrial performance."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ David Lin - AgriProcessing Solutions Inc.

"We upgraded to the Pro Model in April 2024 to handle our sugarcane volume, and after 8 months of 24/7 operation, I can confidently say it’s the most reliable washer we’ve ever used. The auto-calibration feature on the rollers saves us hours in changeover time between crop types. With a throughput of 1,000 kg/h, we’ve reduced labor costs by nearly 40%. The dual-voltage support made integration into our facility seamless, and the stainless steel frame shows zero signs of corrosion, even in our humid processing environment. The 1-year warranty gave us confidence, but honestly, we haven’t needed a single service call."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Amir Hassan - Home Juice Business

"As someone running a home-based citrus juicing business, I needed something durable but not overly industrial. The Base Model fits perfectly under my canopy and runs on 220V, which is all I have at home. I’ve been using it since November 2024—so about 7 months now. It cleans oranges, lemons, and even prickly pears effectively, though I have to manually adjust the rollers each time. Not a big deal for my batch size. The brush roller system removes all the wax and dirt, and cleanup takes less than 10 minutes. Only reason I’m not giving 5 stars is that I wish it had speed control for more delicate fruits. Still, best investment I’ve made."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Rachel Ng - Tropical Crop Research Institute

"We use this machine in our pre-processing lab for experimental citrus and sugarcane varieties. Purchased the Advanced Model in February 2025 for its modular design and food-grade compliance. After 4 months of daily use, it’s proven indispensable. The 99.5% cleaning efficiency ensures consistent sample quality, critical for our studies. The dual spray nozzles and stainless steel construction meet our hygiene protocols, and we appreciate the option to detach and sanitize the rollers. Our team also values the customization—being able to adapt roller spacing for test crops is a huge advantage over fixed systems."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Chef Lena Torres - FreshPress Juice Bar Chain

"We installed two Pro Models across our production kitchens in August 2024. Eight months in, and they’ve handled over 200,000 lbs of citrus and cactus fruit with zero downtime. The high-capacity conveyor system keeps up with peak demand, and the FDA-compliant SUS 304 steel gives our food safety auditors peace of mind. Staff love how quiet and smooth it runs compared to older plastic-based washers. Setup was straightforward, and the supplier provided excellent training. If you’re scaling a fresh produce business, this machine is worth every penny."Purchase Date: August 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Brooks - Post-Harvest Technology Specialist

"After evaluating over 30 fruit washing systems, I recommend the ZZHL Sugarcane Washing Machine—particularly the Pro Model—for operations prioritizing hygiene, throughput, and material longevity. Its SUS 304 stainless steel construction exceeds FDA standards, and the adjustable roller system offers unmatched flexibility for mixed-crop processors. The 1,000 kg/h capacity makes it ideal for industrial adoption, while the dual-voltage design supports global deployment."

Maria Fernandez - GFSI Auditor & Consultant

"In my audits, material compliance is non-negotiable. The ZZHL machine’s food-grade stainless steel and corrosion resistance make it one of the few washers I confidently endorse for HACCP and ISO 22000 environments. The hygienic conveyor design prevents biofilm buildup, and the ease of disassembly for cleaning aligns with preventive maintenance best practices."

Posted: 2 days ago

"Switched from manual scrubbing to this machine last month. Huge time saver. Handles thick cane stalks without jamming. Built like a tank."

Posted: 1 week ago

"Used daily during peak season. Stainless steel wipes clean in minutes. Adjustable rollers make it easy to switch between lemon and grapefruit sizes."

Posted: 3 weeks ago

"Powerful and reliable. Only note is slight vibration at max speed, but doesn’t affect performance. Great value for industrial use."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.