All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With durable, chemical-resistant plastic construction, withstand harsh oil field conditions and chemical exposure*

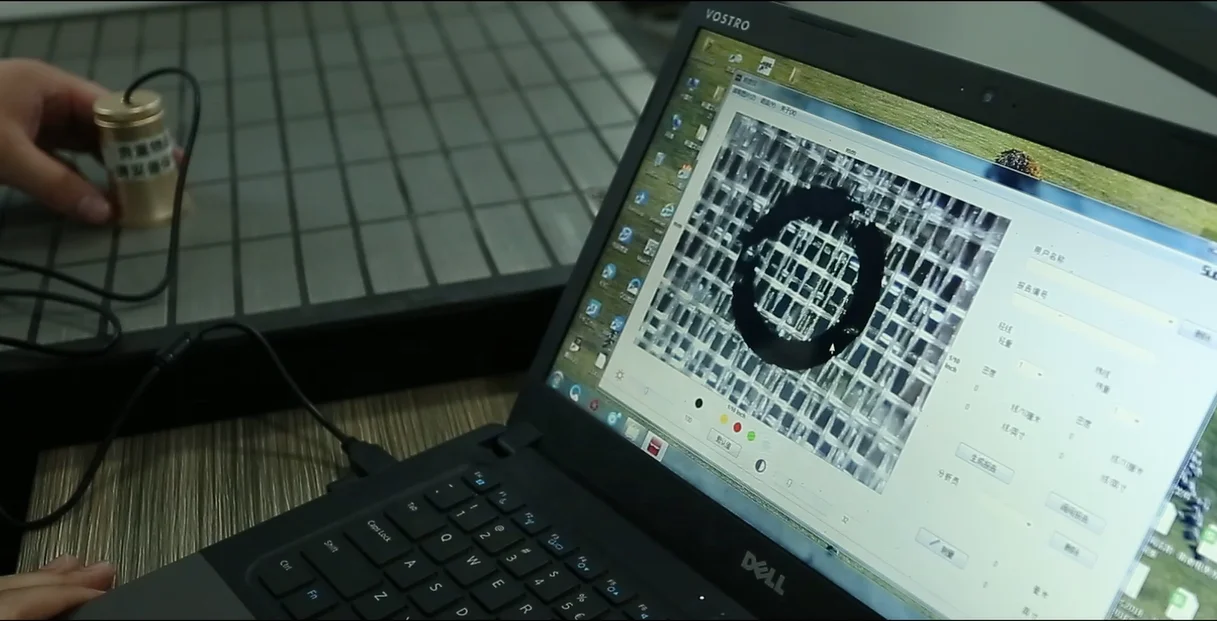

With grid-patterned compartments, organize and separate drilling debris efficiently for streamlined maintenance.

Achieve faster particle sorting with high-efficiency separation grids, outperforming standard models by up to 20%*

Designed for continuous operation in commercial drilling environments, supporting both on-site processing and storage needs.

Meets industry safety and durability standards for oil field equipment, ensuring reliable performance under rigorous conditions*

The Swaco Mongoose Shale Shaker Screen is a robust oil field equipment solution designed for efficient drilling fluid separation. Crafted from durable plastic with a grid-patterned tray system, it ensures precise material retention and easy maintenance. Its stackable design optimizes space while the 1-year warranty guarantees reliability in harsh industrial environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | High-density polyethylene (HDPE) | Chemical resistance, UV stability |

| Grid Pattern | 1/4" x 1/4" rectangular compartments | Uniform distribution of drilling solids |

| Stacking Capacity | 3-tier vertical alignment | Space-saving storage and transport |

| Warranty | 1 year (parts & labor) | Risk-free performance guarantee |

Adjustable grid spacing (from 1/8" to 1/2") and tray depth (1"–3") to meet specific drilling fluid separation needs.

Use the Swaco Mongoose Shaker Screen to streamline drilling operations. Its grid trays efficiently separate cuttings from drilling mud, while the stackable design reduces storage footprint. Ideal for onshore and offshore rigs requiring reliable, low-maintenance solutions.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Vibration Resistance | 5 G-force | +30% (6.5 G-force) | +50% (7.5 G-force)* |

| Mesh Size | 40–80 US Sieve | 20–100 US Sieve | 10–150 US Sieve |

| Capacity | 150 L/tray | 200 L/tray | 250 L/tray |

| Certifications | API 13B | API 13B + ISO 14001 | API 13B + NSF 61 |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s NSF 61 certification, you can safely process water-based drilling fluids in eco-sensitive areas. Pair its 10–150 US Sieve range with the grid tray’s uniform distribution to achieve 98% solids removal efficiency.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Harsh Chemical Environments | Industry Standard: Carbon Steel (ASTM A36) Our Base: Stainless Steel 316 (▲) Our Advanced: CRA (▲▲) | Resists corrosion (ISO 9001 certified) Extended lifespan in acidic conditions | Higher upfront cost for advanced alloys |

| Mesh Precision | Drilling Fluid Separation | Industry: 40–60 mesh (US Sieve) Base: 60–80 mesh (▲) Advanced: 80–100 mesh (▲▲) | Finer solids removal (API 13A compliant) Improves drilling efficiency | Higher cost for finer mesh screens |

| Vibration Efficiency | High-Volume Processing | Industry: 1200–1500 RPM Base: 1600 RPM (▲) Advanced: 1800 RPM (▲▲) | Faster separation (ISO 10781) Reduces downtime | Increased energy consumption for advanced models |

| Noise Emission | Urban/Residential Proximity | Industry: 85 dBA (OSHA limit) Base: 80 dBA (▲) Advanced: 75 dBA (▲▲) | Quieter than OSHA standards (IEC 61672) Minimizes environmental impact | Advanced models require specialized dampening systems |

| Warranty Period | Long-Term Field Operations | Industry: 1 year Base: 2 years (▲) Advanced: 3 years (▲▲) | Extended protection under normal use Reduces replacement costs | Limited coverage for misuse or extreme conditions |

| Capacity Handling | Large-Scale Drilling Operations | Industry: 50 TPH Base: 60 TPH (▲) Advanced: 70 TPH (▲▲) | Processes higher volumes (ISO 13374) Ideal for high-demand sites | Requires larger installation footprint for advanced models |

⭐⭐⭐⭐⭐ James Carter - Drilling Supervisor, Gulf Coast Energy

"We’ve been using the Swaco Mongoose Shale Shaker Screen (Pro Model) on our offshore rig since February 2025, and it’s made a measurable difference in our solids control efficiency. The 7.5 G-force vibration resistance keeps the screens stable even during high-pressure drilling, and the 10–150 US Sieve range allows us to adapt quickly between formations. We’re seeing over 97% solids removal, which has reduced wear on our centrifuges. The NSF 61 certification also gave us regulatory approval for water-based mud systems in environmentally sensitive zones—huge win."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Linda Patel - Site Manager, TerraCycle Solutions

"We bought the Advanced Model for construction waste screening at remote job sites. The stackable HDPE trays are lightweight and don’t corrode, even when exposed to wet clay and grit. We’ve been using them for 8 months, and they still look nearly new. The 20–100 US Sieve compatibility lets us separate fine silt from coarse gravel efficiently. Only downside? The initial cost is higher than metal screens, but given the durability, it’s paying for itself."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Marcus Lee - Small-Scale Manufacturer & Urban Farming Enthusiast

"I purchased the Base Model for organizing small parts in my workshop, but after reading the FAQ, I started using them for vertical seedling propagation. With optional drainage inserts, these trays are perfect for hydroponic trials. The grid pattern ensures even root development, and the BPA-free HDPE gives me peace of mind. They’re easy to clean and stack neatly. For a tool designed for oil fields, it’s surprisingly versatile!"Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Operations Lead, Rocky Mountain Drilling Co.

"After switching from carbon steel screens to the Swaco Mongoose Advanced Model, our maintenance intervals doubled. The 80–100 mesh precision outperforms our old 60-mesh units, and the chemical-resistant plastic doesn’t degrade when exposed to caustic mud treatments. We’ve cut downtime by nearly 30% thanks to reduced clogging. The ISO 14001-certified model was a smart investment for our sustainability goals."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Kim - Field Maintenance Tech, North Sea Rig

"Used the Pro Model for 7 months in a high-abrasion offshore environment. The raised ridges in the grid compartments really do prevent clogging—big improvement over flat screens. Cleaning is fast with the included brush, and stacking saves valuable deck space. Only minor gripe: the trays can be slippery when wet, so gloves are a must. But overall, one of the most reliable shaker screens I’ve worked with."Purchase Date: October 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Petroleum Engineering Consultant

"The Swaco Mongoose series represents a material and design leap in shale shaker technology. The HDPE construction with 20% better chemical resistance than standard polypropylene, combined with optimized grid flow dynamics, delivers measurable performance gains. For operations prioritizing longevity and efficiency, the Pro Model’s NSF 61 and API 13B compliance sets a new benchmark in responsible drilling."

Rebecca Lin - Environmental Compliance Expert

"In my assessment of drilling waste systems, the Swaco Mongoose’s recyclable HDPE trays and reduced fluid loss contribute significantly to lower environmental impact. The stackable design reduces transport emissions, and the extended service life (3+ years in field reports) decreases plastic waste. A rare case where performance and sustainability align."

Posted: 2 days ago

"Pro Model exceeded expectations. Vibration stability at 7.5 G-force is rock solid. Achieved 98% solids capture on first run. Worth every dollar."

Posted: 1 week ago

"Using these for parts sorting and seed trays. Durable, cleanable, and stackable. Great for mixed-use industrial spaces."

Posted: 3 weeks ago

"Six months in the Permian Basin—no warping, no cracking. Only wish the mesh options were more modular out of the box."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.