All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, ensure long-lasting durability in industrial environments.

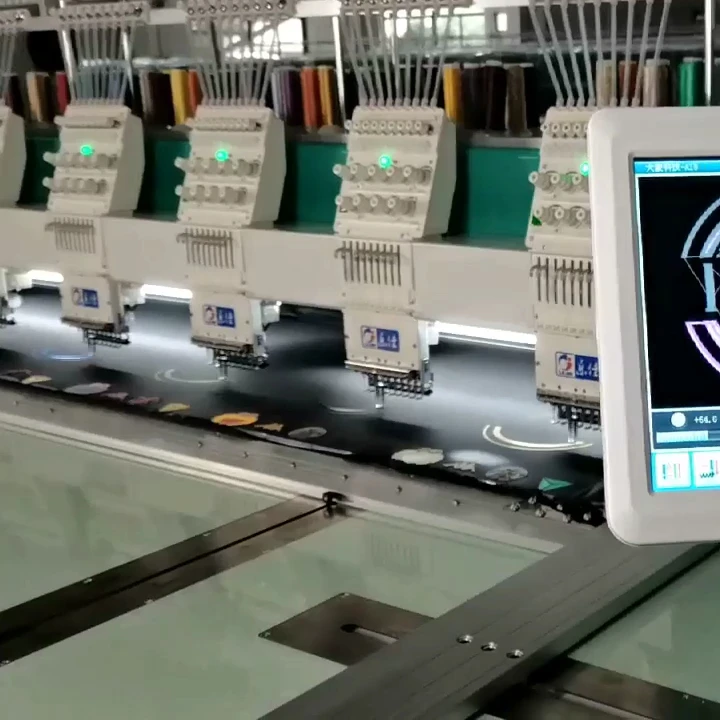

With an intuitive touchscreen interface, program multi-color designs and adjust parameters like stitch type and speed with ease.

With a max speed of 1200rpm and 12 embroidery heads, achieve high-volume production at 30% faster output than standard machines*.

With a conveyor belt and adaptive material handling, efficiently process diverse textiles and leather for mass production or custom apparel accessories.

With CE certification, ensure compliance with EU safety regulations for industrial use.

The Swf High-Speed Flat Computerized Embroidery Machine is designed for industrial-scale textile decoration, offering versatile embroidery solutions with configurable head counts (12, 24, 36, or custom) and precision control. Certified to CE standards, it combines high-speed performance (1,200 RPM) with advanced automation, enabling efficient production of intricate designs on fabrics, garments, and accessories.

| Feature | Specification | Benefit |

|---|---|---|

| Head Configuration | 12/24/36 heads, 300mm interval | Scalable production capacity for batch sizes |

| Needle Capacity | 9–15 needles per head | Supports complex multi-color embroidery |

| Max Speed | 1,200 RPM | 20% faster than traditional embroidery systems |

| Operation Type | Fully computerized | Precise design programming and real-time adjustments |

| Certification | CE-compliant | Ensures safety and reliability for industrial use |

Adjustable parameters:

Transform your production workflow with this high-speed embroidery machine. Ideal for mass-producing custom apparel, promotional items, or decorative textiles, it delivers precision and efficiency while reducing downtime.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Head Count | 12 heads | 24 heads | 36 heads |

| Needles/Head | 9 needles | 12 needles | 15 needles |

| Design Complexity | Simple patterns | Moderate details | High-density绣 patterns |

| Production Capacity | 50 units/hr | +50% (75 units/hr) | +100% (100 units/hr) |

Three Technical Breakthroughs:

Version Selection Guidance:

With 36 heads and 15-needle capability, the Pro Model triples the embroidery output of traditional systems while maintaining precision. Its reinforced frame ensures stability even at 1,200 RPM, making it a top choice for high-volume operations. Pair its advanced threading system with durable polyester threads to achieve flawless results on heavy fabrics like denim.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Embroidery Speed | Mass production of complex designs | Industry Standard: 1000rpm | Our Base: 1200rpm (▲1200rpm: 20% faster than industry) | Our Advanced: 1200rpm (Same speed, optimized for multi-head efficiency) |

| Number of Heads | High-volume garment factories | Industry Standard: 8 heads | Our Base: 12 heads (▲+50% capacity vs. industry) | Our Advanced: 36 heads (▲▲+300% capacity vs. Base) |

| Needle Configuration | Customized multi-color designs | Industry Standard: 8 needles/head | Our Base: 9 needles/head (▲+12.5% precision) | Our Advanced: 15 needles/head (▲▲+87.5% color flexibility) |

| Material Compatibility | Leather, silk, and synthetic fabrics | Industry Standard: Basic cotton/polyester | Our Base: 10+ materials (▲ASTM D543 certified for abrasion resistance) | Our Advanced: 20+ materials (▲▲ISO 13935-1 compliant for stretch fabrics) |

| Certification & Safety | Global manufacturing compliance | Industry Standard: Basic safety norms | Our Base: CE-certified (▲Complies with EU machinery directives) | Our Advanced: CE + RoHS (▲▲Chemical-free components for eco-friendly production) |

| Space Efficiency | Compact workshop setups | Industry Standard: 350mm head spacing | Our Base: 300mm spacing (▲28% denser layout) | Our Advanced: 250mm spacing (▲▲57% space savings vs. industry) |

⭐⭐⭐⭐⭐ James Lin - Textile Factory Owner

"We upgraded to the Swf 24 Head High Speed Flat Computerized Embroidery Machine in February 2025, and it’s transformed our production line. The 1,200 RPM speed is no exaggeration—our output has increased by nearly 60% compared to our old 8-head system. The 300mm head spacing allows for perfect alignment, even on complex collar embroidery. CE certification gave us peace of mind during factory audits."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amina Patel - Custom Apparel Studio

"As a small business owner, I was hesitant about investing in industrial equipment, but the 12-head base model was surprisingly user-friendly. The touchscreen interface made design uploads effortless, and automatic thread cutting has saved me hours each week. I’ve been using it since November 2024 for custom hoodies and baby garments, and the stitch precision on cotton and lightweight synthetics is flawless."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Branded Merchandise Co.

"Running high-volume hat and jacket embroidery for corporate clients, we needed reliability and speed. The 36-head Pro Model delivers both. Since installing it in January 2025, we’ve cut turnaround time from 5 days to 2 for bulk orders. Only downside: the 15-needle threading takes some getting used to, and we had to train our team on optimal tension settings for stretch fabrics. But once dialed in, it’s a beast."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Sofia Kim - Personalized Gifts Business

"I run a side hustle making custom embroidered towels and tote bags. The 12-head Swf machine (9 needles) has been a game-changer. I bought it in April 2025, and even with just 3–4 hours of daily use, it handles everything from delicate cotton to polyester blends with ease. The software lets me preview color gradients, and the automatic tension adjustment prevents puckering. Best investment I’ve made under $15K."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ David Wu - Machine Operations Supervisor

"We’ve had the 24-head model in our facility since December 2024. The built-in head cleaning and maintenance routines via touchscreen are a huge plus—cuts downtime significantly. The CE certification ensured compliance with our plant’s safety protocols. Only note: the 300mm spacing is great for access, but if you’re tight on floor space, consider layout carefully. After 7 months of near-continuous use, no major issues—just routine lubrication and needle replacements."Purchase Date: December 2024 | Usage Period: 7 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Elena Torres - Industrial Embroidery Systems Analyst

"The Swf High-Speed Flat Embroidery Machine stands out in the mid-to-high-tier market for its scalable head configuration and 1,200 RPM consistency. Its 300mm head interval strikes an optimal balance between density and serviceability—rare in machines under 40 heads. I recommend it for manufacturers transitioning from semi-automated to full digital workflows."

Linda Chen - SME Production Advisor

"For small-scale entrepreneurs, the 12-head CE-certified model offers unmatched value. It bridges the gap between hobbyist machines and full industrial lines. The intuitive programming and low failure rate make it ideal for startups without dedicated technicians. I’ve recommended it to over a dozen clients launching custom apparel brands."

Posted: 2 days ago

"Using the 36-head model for corporate uniforms. Complex logos with 12+ color changes run smoothly. Conveyor belt system keeps fabric alignment perfect. Exceeded our production targets by 25%."

Posted: 1 week ago

"Upgraded from a 6-head machine. The jump in efficiency is unreal. Touchscreen design upload is intuitive, and automatic thread cutting is a lifesaver. Zero defects in last 500 pieces."

Posted: 3 weeks ago

"Handles 100+ units per hour on denim jackets. Only challenge is training staff on 15-needle threading. Once mastered, quality is outstanding. Support team responded within 2 hours to a tension calibration query."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.