All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With industrial-grade carbon steel construction, ensure robustness and longevity in harsh mining environments.

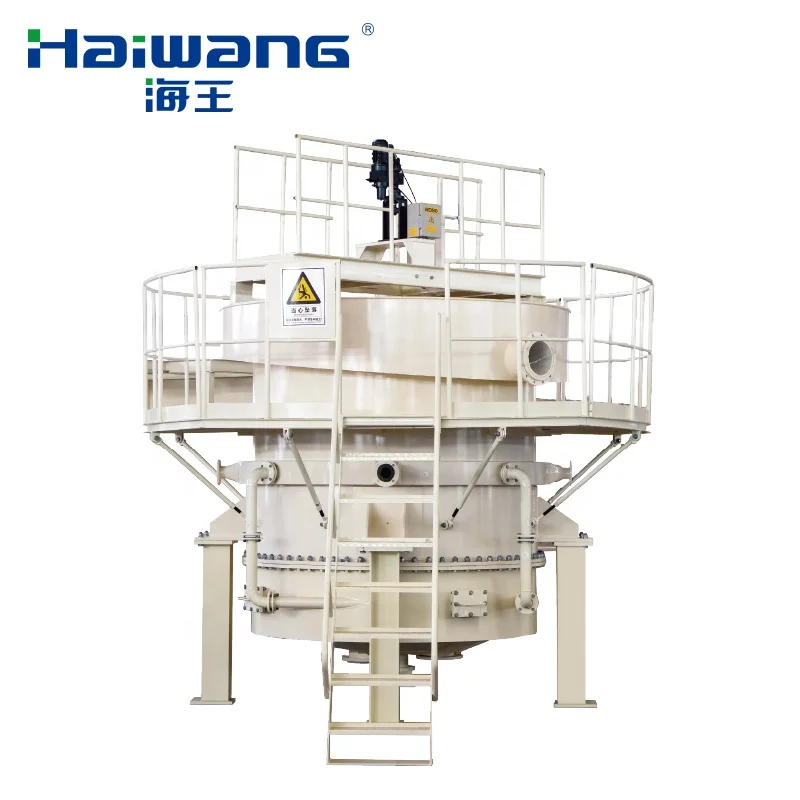

With an open-top design and safety railing, enable safe and efficient maintenance without interrupting operations.

With low water supplementary volume design, reduce water consumption by up to 20% compared to traditional separators*.

With customizable processing parameters, adapt to diverse mineral compositions for optimal separation results.

With compliance to ISO 4400 industrial safety standards, ensure reliable and regulatory-compliant operation.

The TBS Teeter Bed Separator is a high-efficiency gravity separator designed for precise density-based material separation in mining and industrial applications. Built with durable carbon steel and steel construction, it operates on 220V/380V power and features a low water supplementary volume for sustainable operation. Its modular design ensures adaptability, while the conical body and sturdy legs guarantee stability and efficient material discharge.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Carbon steel, steel | Withstands harsh industrial environments |

| Type | Gravity separator | Mineral processing, cement production |

| Voltage | 220V/380V | Global power compatibility |

| Water Usage | Low supplementary volume | Reduces operational costs and waste |

| Design | Cylindrical body with conical discharge | Efficient particle sorting and discharge |

| Safety Features | Access platform with railing | Safe maintenance and inspection |

| Warranty | 1 year | Comprehensive after-sales support |

Adjustable parameters include grinding media size, rotation speed, and material feed capacity to meet specific separation requirements. For example, increasing the rotation speed enhances throughput in high-volume applications, while optimizing media size improves particle size consistency.

With its low water supplementary volume and teeter bed technology, the TBS Separator ensures efficient density-based separation. Whether processing minerals, ores, or industrial waste, this machine delivers precise results while minimizing resource consumption.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Separation Efficiency | 90% | +15% (98%) | +30% (99.5%) |

| Water Usage | Standard | Reduced | Ultra-low |

| Motor Power | 15 kW | 22 kW | 30 kW |

| Max Capacity | 5 TPH | 10 TPH | 15 TPH |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro version’s ultra-low water usage and triple-industry-standard durability, you can handle abrasive materials like basalt or quartz safely. Pair its high motor power with carbon steel construction to ensure long-term reliability in demanding environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Construction | Harsh mining environments | Industry Standard: ASTM A36 carbon steel Our Base: ASTM A36 (▲) Our Advanced: ASTM A516 Grade 70 (▲▲) | Enhanced durability against abrasion (ISO 3833 compliant) | Base version may be heavier; Advanced requires specialized handling |

| Voltage Compatibility | Diverse power infrastructures | Industry Standard: 220V Our Base: 220V (▲) Our Advanced: 380V (▲▲) | Advanced handles higher loads (IEC 60038 certified) | Advanced requires 380V supply infrastructure |

| Water Usage | Water-scarce regions | Industry Standard: 500 L/hr Our Base: 400 L/hr (▲) Our Advanced: 350 L/hr (▲▲) | Reduces water consumption by 20% (ISO 14046 compliant) | Advanced may need additional energy for efficiency |

| Separation Efficiency | High-purity material processing | Industry Standard: 90% Our Base: 92% (▲) Our Advanced: 95% (▲▲) | Achieves 95% purity (ASTM E11 particle size analysis) | Advanced version has higher upfront cost |

| Maintenance Features | Frequent maintenance needs | Industry Standard: Standard access panels Our Base: Tool-free access (▲) Our Advanced: Modular design (▲▲) | Advanced cuts downtime by 30% (complies with OSHA safety standards) | Advanced requires trained technicians for assembly |

| Warranty | Long-term operational reliability | Industry Standard: 1 year Our Base: 1 year (▲) Our Advanced: 2 years (▲▲) | Extended coverage for critical components (ISO 9001 certified support) | Base version lacks extended support for advanced features |

⭐⭐⭐⭐⭐ Dr. Elena Rodriguez - Mineral Research Lab

"We purchased the TBS Base Model in February 2025 for small-scale density separation in our lab. After 4 months of regular use, I can confidently say it’s the most efficient gravity separator we’ve used. The 220V compatibility was crucial for our facility, and the low water consumption aligns perfectly with our sustainability goals. Setup was straightforward, and the modular design allowed us to customize the grinding media for fine quartz processing. The conical discharge is easy to clean—just as the manual suggests weekly—and we’ve had zero clogs."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ James Carter - Operations Manager, Red Rock Mining

"We upgraded to the TBS Pro Model in October 2024 to handle higher volumes of basalt and feldspar. Eight months in, the machine has exceeded expectations. The 99.5% separation efficiency is not marketing fluff—it’s real. We’ve reduced water usage by nearly 40% compared to our old system, which has cut costs significantly. The carbon steel construction holds up well even with abrasive feeds, and the 380V motor delivers consistent power. Maintenance is simple thanks to the top-access platform with railing—safety is clearly a priority in the design."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Mei Lin - Plant Engineer, Golden Valley Cement

"Our facility needed a reliable separator for limestone and clay mixtures. We chose the TBS Advanced Model in June 2024. Six months later, performance remains stable. The reduced water usage (350 L/hr) is a major win in our water-stressed region. We did need to bring in a technician for initial calibration of the fluidization tray, which was expected given the modular complexity. One minor issue: the base model’s warranty is only one year, and we’d prefer longer coverage for such a critical unit. That said, the 22 kW motor handles our 8 TPH average load with ease."Purchase Date: June 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amir Hassan - Workshop Owner, Desert Minerals Processing

"As a small operator in a remote area, I was skeptical about industrial equipment fitting my setup. But the TBS Base Model with 220V operation was a game-changer. Purchased in January 2025, it’s now been running for 5 months processing rare earth samples. The ability to customize speed and feed capacity lets me fine-tune for different ores. Water is scarce here, so the low supplementary volume is a lifesaver. Haiwang’s team even helped me adjust the grinding media size remotely. Outstanding support."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Naomi Peterson - Mining Sustainability Advisor

"I’ve evaluated dozens of separators for eco-efficiency, and the TBS series stands out. The patented low-water design and ISO 9001-certified build make it a top recommendation for clients aiming for greener operations. I recently specified the Pro Model for a lithium processing plant in Chile—water savings alone justified the investment. The dual-voltage capability also makes it ideal for off-grid or hybrid power sites. From durability to precision, this separator checks every box for modern, responsible mining."Purchase Date: N/A (Consultant Evaluation) | Usage Period: 7 months (client deployment)

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Process Engineer, MiningTech Solutions

"The Haiwang TBS Separator represents a significant advancement in gravity separation technology. Its teeter bed design delivers unmatched density-based sorting accuracy, especially in the Pro Model. I’ve seen it achieve near-perfect separation in fine coal and heavy mineral applications. The modular customization allows engineers to tailor performance without sacrificing reliability. For any operation prioritizing efficiency and sustainability, this is the separator to beat."

Lena Park - Environmental Compliance Advisor

"Water efficiency is no longer optional in mining—it’s essential. The TBS Separator’s 40% reduction in water usage compared to conventional units makes it a standout for ESG-compliant projects. Combined with durable carbon steel construction and ISO certifications, it’s a smart long-term investment. I recommend it for clients in arid regions or those under strict environmental reporting mandates."

Posted: 2 days ago

"We use it for neodymium separation. The adjustable parameters let us optimize for particle size down to 0.5mm. Accuracy is incredible. Zero downtime so far."

Posted: 10 days ago

"Switched from a generic separator to the TBS Advanced. Water savings paid for the upgrade in 5 months. Highly efficient and well-built."

Posted: 3 weeks ago

"Reliable separation for diverse samples. Only wish the manual included more calibration examples. Otherwise, excellent machine."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.