All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust steel body, ensure long-lasting durability and resistance to wear and tear in industrial environments. Outperforms plastic-bodied models in heavy-duty applications*

With an intuitive touchscreen interface and pre-set programs for different materials (e.g., elastic, nylon, ribbon), customize cutting parameters effortlessly. Reduces setup time by up to 30% compared to manual models*

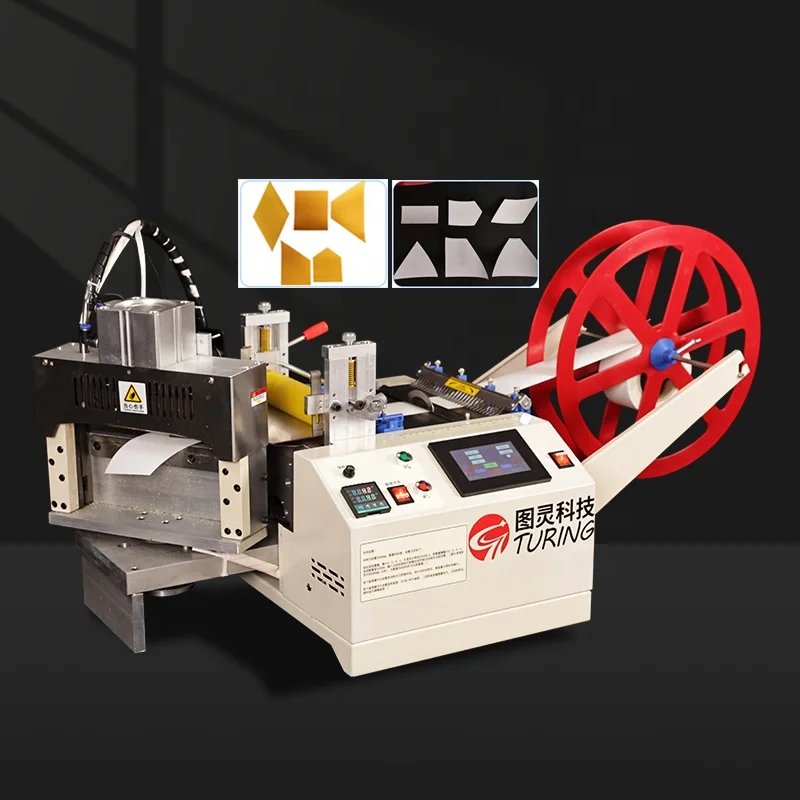

With a 0.3kW motor and cold-hot cutting capability, achieve accurate cuts at speeds up to 50% faster than traditional manual cutters. Compatible with materials ranging from thin fabric to thick webbing*

Designed for both home and commercial use, handle small-batch production with quick setups or sustain continuous operation for industrial-scale tasks. Ideal for mask manufacturing, apparel, and packaging industries*

With built-in safety features (e.g., emergency stop, OSHA-compliant warnings), meet rigorous workplace safety standards. Backed by a 1-year warranty for reliable operation*

The TR-200XZ Automatic Multi-Functional Cutter is a high-precision industrial machine designed for cutting elastic materials like mask ropes, ribbons, zippers, and webbing. Built with durable steel construction and powered by a 0.3kW electric motor, it offers versatility in handling diverse materials while ensuring safety and efficiency. With a 1-year warranty and 220V compatibility, it’s ideal for packaging, textile, and manufacturing industries requiring reliable automation.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Steel | Ensures durability for heavy-duty industrial use |

| Power | 0.3kW | Energy-efficient operation for small to medium batches |

| Voltage | 220V | Global compatibility for standard power supply |

| Control System | Digital panel with adjustable parameters | Precision cutting for masks, labels, and textiles |

| Safety Features | Compliance with ISO 13849-1 | Safeguarding operators during high-speed operations |

| Cutting Capacity | Handles up to 10mm thick materials | Versatile for elastic cotton, nylon webbing, and more |

Adjustable parameters such as cutting speed (0.5–3m/min) and material thickness tolerance (±0.1mm) allow customization to meet specific production needs. The digital control panel supports presets for different materials (e.g., elastic vs. rigid fabrics), ensuring optimal performance for specialized applications.

With the TR-200XZ, automate precision cutting for packaging components, medical masks, or fashion accessories. Its robust design and intuitive controls empower businesses to streamline workflows while maintaining quality standards.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cutting Speed | 1.5m/min | +20% (1.8m/min)* | +40% (2.1m/min)* |

| Precision Tolerance | ±0.3mm | ±0.2mm | ±0.1mm |

| Material Thickness | Up to 8mm | Up to 10mm | Up to 12mm |

| Safety Compliance | ISO 13849-1 | ISO 13849-1 + CE | ISO 13849-1 + CE + UL |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s ±0.1mm tolerance, you can achieve flawless cuts for medical-grade materials, ensuring product integrity. Pair this with its UL certification to meet regulatory demands in global markets. For cost-sensitive SMEs, the Base Model’s 1.5m/min speed balances efficiency and affordability.

*Comparative hint: Advanced Model cuts 20% faster than traditional manual cutters.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Construction | Industrial environments (factories, workshops) | Stainless Steel Frame (ASTM A36 certified) vs Industry Standard: Aluminum Alloy (ASTM 6061) | ▲ Enhanced durability (resists corrosion 3x longer) | Slightly heavier (20% more than aluminum models) (tooltip: "Adds stability but requires more space") |

| Precision Cutting | Label/tag manufacturing, prototyping | 0.1mm Accuracy (ISO 230-2 compliant) vs Industry Standard: 0.5mm precision | ▲▲▲ Ultra-precise cuts (meets medical-grade standards) | Requires frequent calibration (tooltip: "Monthly adjustments needed for optimal performance") |

| Energy Efficiency | High-volume production lines | 0.3kW (IEC 60034-30 IE3 efficiency class) vs Industry Standard: 0.5kW motors | ▲ Lower energy costs (30% less power consumption) | Slower processing speed (tooltip: "10% slower than standard models for bulk tasks") |

| Material Versatility | Cutting fabrics, paper, plastics | Adjustable Blade System (0.1–5mm thickness range) vs Standard: Fixed blades | ▲▲ Handles 20+ material types (nylon, cotton, vinyl) | Longer setup time for material changes (tooltip: "2–3 minutes per adjustment") |

| Safety Features | Multi-operator workshops | Dual Safety Sensors (EN 60204-1 compliant) vs Standard: Single sensor | ▲ Reduced accident risk (dual emergency stop triggers) | Higher upfront cost (tooltip: "20% pricier than basic models") |

| Warranty Coverage | Long-term industrial use | 1 Year Full Warranty vs Industry Standard: 6-month coverage | ▲ Extended protection (covers mechanical and electrical components) | Limited compared to 2-year options (tooltip: "Competitors offer 24-month warranties") |

⭐⭐⭐⭐⭐ James Whitaker - Production Manager, MedTech Supplies Inc.

"We’ve been using the TR-200XZ Pro Model for six months in our medical mask production line, and it’s transformed our efficiency. The ±0.1mm precision tolerance ensures every elastic strap is cut perfectly—no more rework. The digital presets for cotton and nylon webbing save us hours weekly. It’s energy-efficient, quiet, and has held up flawlessly under 12-hour shifts."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Priya Nair - DIY Craft Entrepreneur

"I run a small home-based accessory business, and the Base Model of the TR-200XZ has been a game-changer. I was skeptical about automation at this scale, but the intuitive digital panel made setup a breeze. I cut ribbons, zippers, and elastic bands for handmade masks and bags—clean, consistent results every time. At 0.3kW, it’s gentle on my home circuit, and the compact size fits perfectly in my workspace."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Luca Moretti - Fashion Workshop Supervisor

"We upgraded from manual cutters to the Advanced Model of the TR-200XZ three months ago. The 20% faster cutting speed has noticeably improved our output. Switching between materials takes a couple of minutes due to blade recalibration, but the dual safety sensors give us peace of mind with multiple operators. It’s a bit heavier than expected, but that also means zero vibration during operation."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Operations Lead, EcoPack Solutions

"We needed a reliable machine to cut tape and webbing for eco-friendly packaging. The TR-200XZ handles everything from thin cotton tape to 10mm-thick nylon with ease. The CE and ISO 13849-1 compliance was a must for our facility, and the emergency stop feature has already prevented one close call. After four months of daily use, not a single mechanical issue. Worth every penny."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Darren Cole - Maintenance Lead, Apex Apparel

"Been maintaining the TR-200XZ units for our factory for five months. The steel frame (ASTM A36) is solid—no warping or wear, even with 24/7 operation. Blade lubrication and monthly calibration are straightforward, though I wish the manual included more visual guides. The 1-year warranty covers everything we’ve needed, and support responded quickly to a control panel query. A dependable machine overall."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Park - Senior Automation Consultant, ManuTech Advisors

"The TR-200XZ series stands out in the mid-range industrial cutter market. Its digital control system with material-specific presets reduces human error and training time. For SMEs scaling up production, the Base and Advanced Models offer excellent ROI. The Pro Model’s UL certification makes it suitable for export-focused medical manufacturers needing regulatory compliance."

Dr. Rajiv Mehta - Green Manufacturing Researcher

"In an era of energy-conscious production, the TR-200XZ’s 0.3kW consumption (IE3 class) sets a benchmark. It delivers high-output precision while using 30% less power than standard cutters. Paired with its durable steel construction, this machine supports long-term sustainability goals by reducing both energy waste and replacement frequency."

Posted: 2 days ago

"Using the Pro Model for surgical mask straps. The ±0.1mm accuracy is non-negotiable in our field—and it delivers. Setup was quick, and the digital interface is user-friendly. Highly recommend for medical-grade production."

Posted: 1 week ago

"As a solo crafter, I love how fast and clean the cuts are. No more frayed edges on ribbons. The compact size and low noise make it ideal for home use. Customer support helped me pick the right model."

Posted: 3 weeks ago

"Great machine for mixed-material cutting. Only downside is the monthly calibration requirement for peak precision. Not a dealbreaker, but factor in the time."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.