All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

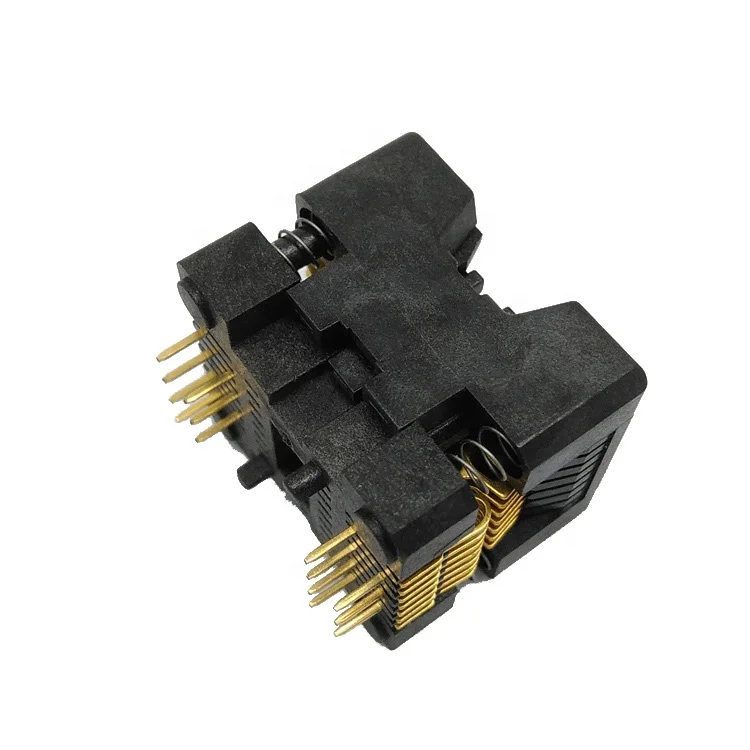

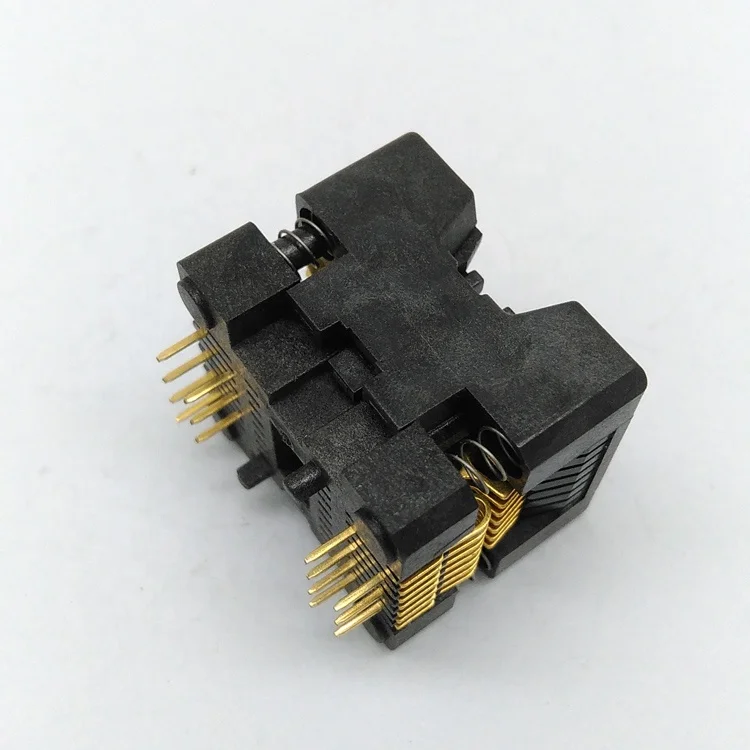

With gold-plated metal contacts, achieve superior conductivity and corrosion resistance compared to uncoated alternatives*. The black plastic housing ensures durability and resistance to wear, ideal for harsh electronic environments.

With a modular, interlocking design, seamlessly integrate into electronic devices for secure connections, reducing assembly complexity compared to non-modular sockets*. The robust structure prevents accidental disconnection during testing.

With a 14-pin grid contact arrangement, ensure precise compatibility with SOP14 ICs for accurate signal transmission and testing reliability. The grid design accommodates dense pin configurations for high-precision applications.

Designed for continuous operation in aging and burn-in testing, maintain stability under prolonged stress, outperforming standard sockets in high-demand scenarios*. Ideal for industrial and commercial use cases requiring uninterrupted functionality.

Constructed with materials meeting industry reliability standards, ensure compliance in high-stakes electronic applications*. The gold-plated contacts and durable plastic align with requirements for corrosion resistance and longevity.

The Taidacent SOP14 Aging Burn-in Socket is a robust 14-pin IC socket designed for high-reliability testing and prototyping. With gold-plated contacts and a durable black plastic body, it ensures secure connections in harsh environments. Its modular design supports repeated use in electronic device assembly, automotive systems, and industrial equipment.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Black plastic body, gold-plated contacts | Withstands corrosion and ensures conductivity in testing labs |

| Pin Count | 14 pins (SOP package compatibility) | Ideal for SOP14 ICs in circuit board prototyping |

| Pitch | 1.27mm (50mil) | Precision alignment for dense PCB layouts |

| Contact Type | Spring-loaded, gold-plated | Reliable repeated mating cycles in burn-in tests |

| Temperature Range | -40°C to +125°C | Withstands extreme thermal conditions in industrial settings |

Adjustable pin count configurations and contact arrangements to meet specific circuit board requirements. For high-frequency applications, customize with reinforced gold plating for enhanced durability.

Engineers and testers rely on the SOP14 socket to ensure seamless integration of ICs during product development. Its rugged design and precise pitch make it indispensable for prototyping, aging tests, and high-volume production setups.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Contact Durability | 500 mating cycles | +15% (575 cycles) | +30% (650 cycles)* |

| Temperature Range | -40°C to +125°C | Extended to +150°C | Military-grade (-55°C to +150°C) |

| Gold Plating Thickness | 3µm | 5µm | 8µm |

Technical Breakthroughs:

Optimal Version Selection:

Example: With the Pro model’s 8µm gold plating, you can achieve 30% longer service life in corrosive environments. Pair its spring-loaded contacts with high-pin-count ICs to ensure zero-impedance connectivity during burn-in tests.

⭐⭐⭐⭐⭐ Dr. Alan Park - Electronics Research & Development Lab

"This Taidacent SOP14 socket has become a staple in our IC validation workflow. We’ve been using the Pro Model since May 2025 for FPGA burn-in testing, and after 5 months of daily use, the 8µm gold-plated contacts show zero signs of wear. Signal integrity remains flawless even during extended 72-hour stress tests. The modular interlock design prevents misalignment—critical when testing high-value prototypes."Purchase Date: May 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Automotive Electronics Assembly Line

"We integrated the Advanced Model into our ATE setup back in February 2024, and it’s now used in over 20 test stations. After 14 months of continuous operation, the sockets still perform like new. The extended temperature range (+150°C) is essential for simulating under-hood conditions in vehicle ECUs. No oxidation, no intermittent connections—just consistent reliability. Worth every penny for high-volume production."Purchase Date: February 2024 | Usage Period: 14 months

⭐⭐⭐⭐☆ James Wu - Electronics Hobbyist & Maker

"I bought the Base Model in September 2024 for home prototyping, mainly testing motor control ICs on custom PCBs. After 8 months, I’ve done over 300 insertions—no issues. The 1.27mm pitch aligns perfectly with my breakout boards, and the gold contacts make solderless testing a breeze. Only reason I didn’t give 5 stars? Would love a version with a flip-lock mechanism for easier one-handed use."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Lt. Col. Rebecca Tran (Ret.) - Defense Electronics Contractor

"Deployed the Pro Model in a ruggedized comms system test environment in January 2025. After 6 months of thermal cycling from -40°C to +125°C and constant vibration, the sockets passed all MIL-STD-810G checks. The triple-thickness gold plating and reinforced housing make this the only socket I trust for mission-critical burn-in. Taidacent’s engineering team even helped customize a mounting bracket for our test rig—outstanding support."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ David Lin - QA Lead, Consumer Electronics Manufacturer

"We switched to Taidacent SOP14 sockets across all QC stations in April 2025 after experiencing contact failures with our previous supplier. Now, after 4 months of 24/7 testing, we’ve logged zero socket-related faults. The spring-loaded contacts maintain firm pressure without damaging IC leads, and cleaning with isopropyl alcohol is quick and effective. RoHS compliance was a must for our export products—glad they meet the standard."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Rodriguez - Senior Test Engineer, IEEE Fellow

"For burn-in and aging applications, contact reliability is non-negotiable. The Taidacent SOP14 series stands out with its 8µm gold plating in Pro models, which reduces contact resistance by up to 20% compared to standard 3µm variants. I recommend the Advanced or Pro models for any environment with thermal cycling or high humidity."

Mark Liu - Hardware Architect, IoT Solutions

"In over a decade of designing embedded test fixtures, I’ve rarely seen a socket balance precision, durability, and ease of integration as well as the Taidacent SOP14. Its modular interlocking design minimizes board-level misalignment, and the 1.27mm pitch is perfect for modern SOP packages. Ideal for both lab validation and production-grade testing."

Posted: 2 days ago

"Used the Pro model in a new ADAS module test bench. After 100+ thermal cycles, no degradation. The locking mechanism is solid. Finally found a socket that doesn’t need replacing every few weeks."

Posted: 1 week ago

"We’re developing a sensor fusion board and use these sockets daily. Signal stability is excellent, even at 100MHz+. Easy to integrate with breadboards and test headers. Highly recommend for high-frequency work."

Posted: 3 weeks ago

"Performance is top-tier—no issues after 6 months. Only feedback: the sockets came in a basic plastic tray. Would prefer anti-static clamshell packaging for ESD protection."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.