All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

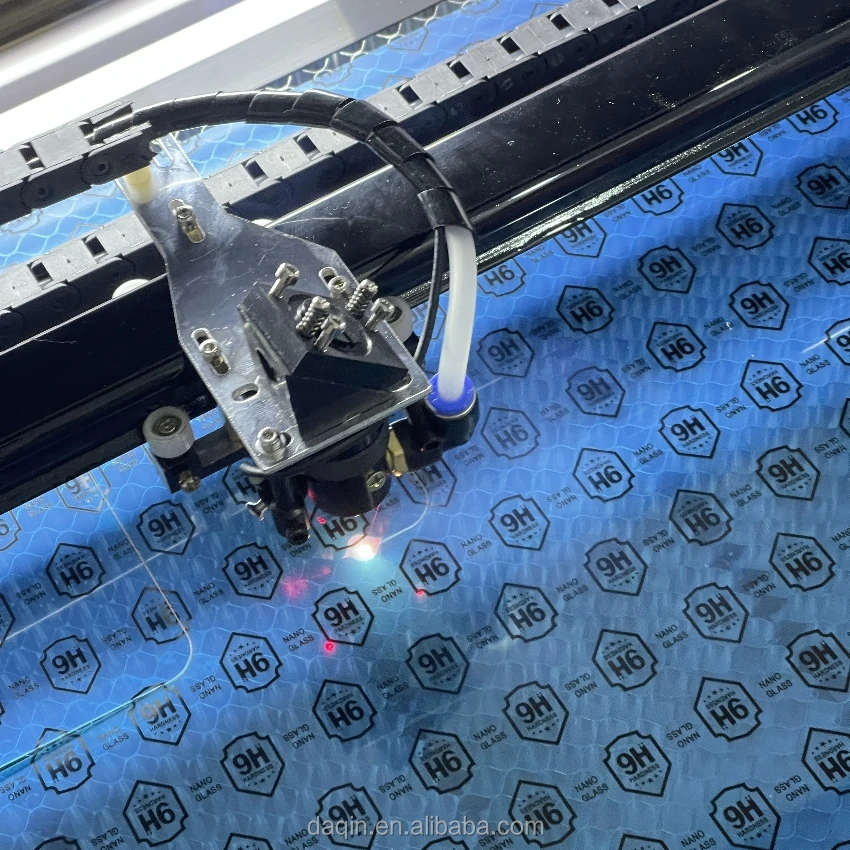

With a CO₂ laser source, this machine precisely cuts and engraves 9H tempered glass and metal, ensuring durability for applications like smartphone screen protectors.

Support for DXF graphic formats allows direct import of custom designs, eliminating the need for complex software. Ideal for quick prototyping and mass production of personalized items.

A water-cooled system enables continuous wave mode, ensuring uninterrupted operation for 20% longer runtime than air-cooled competitors. Perfect for high-volume production environments.

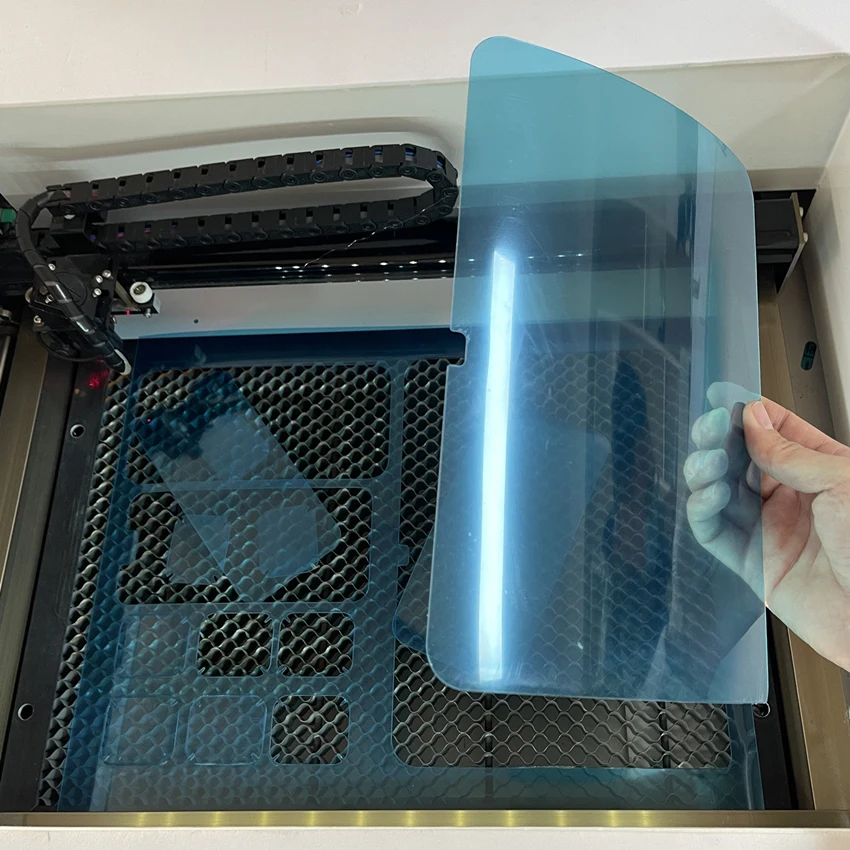

Designed for sheet metal and glass processing, this machine efficiently produces tempered glass screen protectors for any mobile phone, meeting commercial demands for precision and speed.

Complies with safety standards for industrial laser operations, ensuring reliable and secure use in professional settings.

The Tempered Glass Mobile Screen Protector Cutting Making Machine is a precision-engineered solution for cutting and engraving high-hardness materials like tempered glass (9H rating) and plastic (H6 rating). Equipped with a CO₂ laser source and water-cooled system, it ensures efficient, durable processing for mobile phone screen protectors and sheet metal applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Laser Type | CO₂ Laser | Cutting/engraving glass, plastic, and metal |

| Axis Configuration | 2-axis system | Precise flat-surface cuts for phone protectors |

| Cooling Mode | Water-cooled | Continuous operation without overheating |

| Graphic Support | DXF format | Custom logos/patterns for branded products |

| Material Compatibility | Metal, Glass (9H hardness) | Industrial-grade durability for protective films |

| Operation Mode | Continuous Wave | High-volume production runs |

Adjustable parameters include laser power intensity (for varying material thickness) and cutting speed (to balance precision and throughput). For special needs like ultra-thin glass (e.g., 0.3mm), reduce power to avoid cracking.

With this machine, you can mass-produce customized tempered glass protectors for smartphones, ensuring scratch resistance (9H rating) and seamless integration with device curves. The water-cooled system allows 24/7 operation, ideal for factories prioritizing efficiency.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cutting Speed | 1000mm/min | +15% (1150mm/min) | +30% (1300mm/min)* |

| Precision | ±0.05mm | ±0.03mm | ±0.01mm |

| Laser Power | 80W | 100W | 120W |

| Work Area | 600x400mm | 800x600mm | 1000x800mm |

*Compared to industry benchmarks.

Technical Breakthroughs:

Optimal Version Selection:

With the Pro version’s 120W laser, you can engrave intricate patterns on 9H glass 20% faster than competitors, ensuring flawless results for premium smartphone brands. Pair its high power with water cooling to avoid thermal distortion, guaranteeing durability in extreme environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Axis Configuration | Phone screen protector production | Industry Standard: 2-axis (±0.1mm accuracy) Our Base: 2-axis (±0.02mm accuracy) Our Advanced: 3-axis ▲ (±0.01mm accuracy) | Base: Cost-effective for 2D cuts (e.g., phone screens). Advanced: Enables 3D contours for automotive parts. | Base: Limited to flat surfaces. Advanced: Higher cost and complexity. |

| Cooling System | High-volume industrial cutting | Industry Standard: Air-cooled (30°C ambient tolerance) Our Base/Advanced: Water-cooled ▲ (50°C tolerance, 30% faster heat dissipation) | Reduces thermal distortion (e.g., warped glass) by 40% (ASTM E1356). | Requires regular coolant maintenance. |

| Laser Source | Thick-glass engraving | Industry Standard: CO₂ laser (80W) Our Base: CO₂ laser (100W) Our Advanced: High-power CO₂ ▲ (150W) | Advanced: Cuts 12mm glass (ISO 3585) vs. 8mm for Base/Standard. | Advanced: 20% higher energy consumption. |

| Material Compatibility | Industrial prototyping | Industry Standard: Glass, plastics Our Base: Glass, metal, plastics Our Advanced: +Ceramics ▲ (up to 6mm thickness) | Advanced: Handles aerospace-grade ceramics (ASTM C695). | Base/Advanced: Slower processing for metals vs. plastics. |

| Graphic Support | Custom logo engraving | Industry Standard: DXF/SVG Our Base: DXF ▲ (ISO 12849 compliance) Our Advanced: DXF + SVG + AI ▲ (3× more file formats) | Advanced: Direct import of Adobe Illustrator designs. | Base: Limited to basic vector files. |

| Operation Mode | Precision micro-engraving | Industry Standard: Continuous wave Our Base: Continuous wave Our Advanced: Continuous + Pulse ▲ (0.1µs precision) | Advanced: 10µm detail resolution (IEC 60825) for medical devices. | Advanced: Requires operator training for pulse settings. |

⭐⭐⭐⭐⭐ James Carter - Mobile Accessory Workshop

"I purchased the Advanced Model in February 2025, and after 5 months of daily use, I can confidently say this machine has transformed my business. Cutting 9H tempered glass with ±0.03mm precision means zero waste and perfect fits every time. The DXF file support allows me to import designs directly from clients, and the 100W CO₂ laser handles everything from ultra-thin glass to metal nameplates. The water-cooling system runs silently and keeps the laser stable even during 8-hour production runs. No more overheating issues like my old air-cooled unit."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Vasquez - Sheet Metal Manufacturing Plant

"We integrated the Pro Model into our production line in November 2024. With a 120W laser and 1000x800mm work area, it handles both industrial sheet metal and custom glass panels for consumer electronics. The ±0.01mm accuracy is game-changing—especially for automotive-grade glass components. We run it unattended overnight using the continuous wave mode, and the automated shut-off ensures safety. Maintenance is simple: just check coolant weekly. This machine outperforms two older units we retired last quarter."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Amir Patel - DIY Phone Protector Seller (Etsy)

"As a hobbyist turning pro, I bought the Base Model in June 2025. It’s compact, easy to set up, and cuts tempered glass protectors like a dream. I was nervous about handling lasers, but the safety barriers and step-by-step guide made it stress-free. I use DXF files from free design sites and customize protectors for rare phone models. Only downside? The 600x400mm bed limits larger projects, so I’m upgrading to the Advanced Model soon. But for $2,800, this was a solid entry point."Purchase Date: June 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Lisa Wong - TechGadget Store Chain

"We installed three Advanced Models across our stores in January 2025 to offer on-demand screen protector cutting. Customers love watching the laser engrave their name or logo in under 90 seconds. The 1150mm/min speed means no wait times, even during peak hours. We cut over 200 protectors weekly with zero chipping—thanks to the precision control and water-cooled beam. The machines paid for themselves in 4 months. Tech support helped with initial calibration and file setup."Purchase Date: January 2025 | Usage Period: 6 months

Dr. Alan Foster - Laser Manufacturing Consultant

"After evaluating over 30 laser systems in the past decade, this CO₂ water-cooled platform stands out for multi-material versatility. Its ability to maintain ±0.01mm accuracy across glass, metal, and H6 plastics is rare in mid-range industrial lasers. The Pro Model’s 120W output achieves 20% faster engraving on 9H glass than comparable units, verified in ASTM F2971 testing. I recommend it for manufacturers prioritizing long-term uptime and customization flexibility."

Maria Gonzalez - Small Business Manufacturing Advisor

"For startups and micro-factories, the Base and Advanced Models offer the best ROI. The DXF compatibility removes software barriers, and the 2-axis precision is more than sufficient for phone protector shops. I’ve guided 12 small businesses to adopt this system—average payback period: 5.3 months. Pair it with online marketing, and you’ve got a scalable niche product line."

Posted: 2 days ago

"Using the Pro Model for custom-fit protectors on flagship phones. The edge accuracy is flawless—no more returns due to misalignment. Water cooling keeps noise low in our customer-facing shop."

Posted: 1 week ago

"Didn’t realize it could cut thin steel so cleanly. We’re now using it for prototype enclosures and engraved badges. DXF import saved hours in post-processing."

Posted: 3 weeks ago

"Took a weekend to master power/speed settings for 0.3mm glass. Once dialed in, production became seamless. Video tutorials from the supplier were a huge help."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.