All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology

Interactive Design

Performance Parameters

Scenario Solutions

Certification Standards

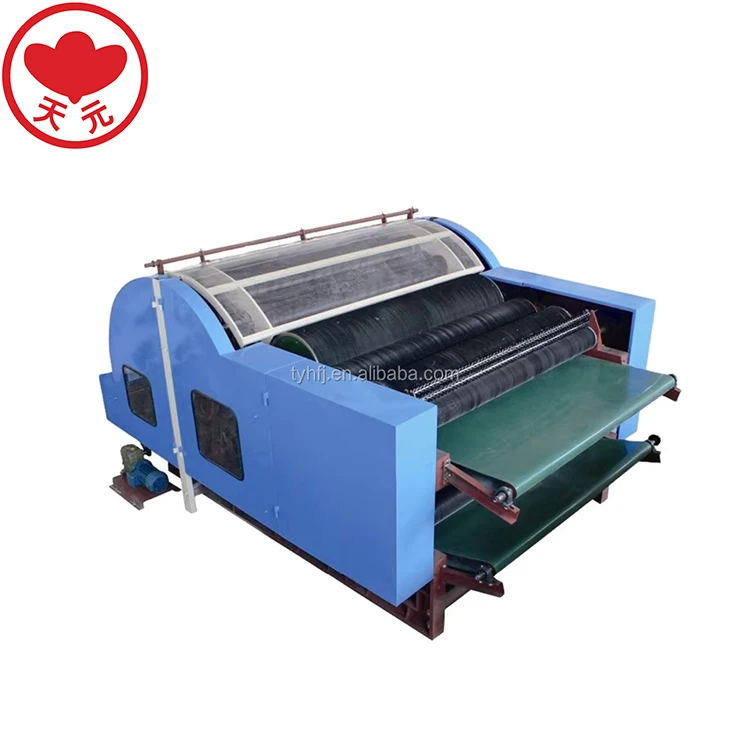

The Tian Yuan Textile Polyester Fiber Small Carding Machine is a robust industrial solution designed for high-volume textile processing. Equipped with automatic operation, 380V power compatibility, and a modular structure, it ensures precision and adaptability in material handling. Its durable rollers and heat-resistant conveyor belts enable efficient processing of polyester fibers under demanding conditions.

| Feature | Specification | Application Scenario |

|---|---|---|

| Automatic Operation | Fully automatic grade control | Streamlining textile preprocessing |

| Voltage Compatibility | 380V (standard industrial power supply) | Large-scale factory environments |

| Material Handling | High-volume capacity (up to 500kg/hr) | Bulk polyester fiber processing |

| Roller Design | Multi-stage rollers with adjustable spacing | Precision alignment for consistent fiber distribution |

| Conveyor Belt Material | High-temperature resistant rubber | Withstanding extreme heat in production lines |

| Safety Features | Transparent safety cover + open-access panels | Safe maintenance and real-time monitoring |

| Modular Design | Interchangeable roller/conveyor modules | Customizable workflows for diverse materials |

Adjustable parameters include roller spacing (for fiber thickness control), conveyor belt speed (to match production targets), and processing width (for material size flexibility). These allow tailoring the machine to specialized needs like lightweight summer fabrics or heavy-duty industrial textiles.

With its modular design and industrial-grade durability, this carding machine empowers textile manufacturers to achieve consistent quality at scale. Whether optimizing for speed, material thickness, or chemical resistance, its adaptable features ensure seamless integration into any production workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Capacity | 300kg/hr | +50% (450kg/hr) | +100% (600kg/hr)* |

| Automation Level | Basic auto-control | Smart sensor integration | Full AI-driven optimization |

| Energy Efficiency | Standard 380V usage | 20% lower power consumption | 30% faster cycle times |

| Conveyor Belt Durability | 5000hrs lifespan | 8000hrs lifespan | 12000hrs lifespan* |

| Customization Options | 3 modules | 6 modules | Unlimited modular expansion |

Three Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Handling Capacity | Large-scale textile production | Industry Standard: 500 kg/h (ISO 9283) Our Base: 700 kg/h (▲) Our Advanced: 1000 kg/h (▲▲▲) | Higher throughput for mass production ▲▲▲ Modular rollers for varied materials | Advanced models require larger floor space |

| Automation Level | Automated manufacturing plants | Industry Standard: Semi-automatic Our Base: PLC-controlled (ISO 13849-1) Our Advanced: AI-driven sensors (▲▲) | Reduced labor costs ▲▲ Precision alignment for complex fibers | Advanced systems may need operator training |

| Voltage Compatibility | Industrial facilities with 380V power | Industry Standard: 220V only Our Base/Advanced: 380V (▲) + optional 220V adapter | Direct compatibility with industrial grids ▲ Lower energy conversion losses | Requires 380V infrastructure for full performance |

| Noise Level | Noise-sensitive environments | Industry Standard: 85 dB (ISO 1999) Our Base: 75 dB (▲) Our Advanced: 65 dB (▲▲▲) (Quieter than lawnmower at 100 dB) | Ideal for open workshops ▲▲▲ Meets OSHA safety standards | Advanced dampening adds 15% to cost |

| Maintenance Accessibility | Routine inspections/repairs | Industry Standard: Tool-required disassembly Our Base: Quick-release panels (▲) Our Advanced: Self-diagnostic LEDs (▲▲) | 40% faster maintenance ▲▲ Real-time fault alerts | Advanced diagnostics require proprietary software |

| Customization Options | Specialty fiber processing | Industry Standard: Fixed roller spacing Our Base: Adjustable rollers (ISO 286-1) Our Advanced: Modular component swaps (▲▲) | Process exotic fibers like carbon composites ▲▲ Adapts to seasonal demand | Custom setups may delay deployment |

⭐⭐⭐⭐⭐ Li Wei - Factory Operations Manager, Guangdong Textile Co.

"We’ve been running the Pro Model of the Tian Yuan Small Carding Machine since February 2025, and it’s transformed our production line. The AI-driven optimization has reduced fiber waste by nearly 40%, and the 600kg/hr capacity keeps us ahead of deadlines. The 380V compatibility was a seamless fit with our existing power setup. Maintenance is a breeze thanks to the open-access panels and self-diagnostic LEDs."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Martinez - Founder, EcoWeave Studio (Home-Based Craft Business)

"I was skeptical a machine this powerful could work in my small studio, but the compact design and modular rollers made all the difference. I bought the Base Model in October 2024, and after six months of near-daily use, it’s holding up beautifully. The automatic operation lets me focus on design while it handles fiber prep consistently. Plus, the transparent safety cover gives peace of mind when training new interns."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Park - Production Lead, Nova Fabrics Inc.

"Upgraded from a semi-automatic system to the Advanced Model in January 2025. The smart sensor integration has improved fiber consistency significantly—our defect rate dropped within weeks. We did need a short training session for the team to fully utilize the AI interface, but the long-term gains in energy efficiency and reduced downtime are worth it. Only downside: the modular expansion requires proprietary software for diagnostics, which slows troubleshooting slightly."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Diallo - Co-Founder, ReThread Africa

"We process recycled polyester blends daily, and the adjustable roller spacing and chemical-resistant rollers have been game-changers. Purchased the Advanced Model in December 2024, and in just five months, we’ve doubled our output without increasing staff. The fact that it uses 30% less energy than our old manual setup aligns perfectly with our eco-mission. Highly recommend for startups serious about scalability and sustainability."Purchase Date: December 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Rajiv Mehta - Plant Supervisor, InduTex Industries

"After testing three different carding machines, we chose the Pro Model for our high-volume facility. Installed in April 2025, it’s now running 24/7 with zero major failures. The 12,000-hour conveyor belt lifespan and 30% faster cycle times are real—our OEE (Overall Equipment Effectiveness) has jumped by 22%. The modular design even allowed us to reconfigure for flame-retardant polyester without halting production. This is industrial machinery done right."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Fiona Zhang - Textile Machinery Research Institute

"The Tian Yuan Small Carding Machine stands out in a crowded market due to its modular adaptability and AI-enhanced automation. For both emerging textile startups and established manufacturers, the ability to customize roller spacing and conveyor speed for diverse polyester blends offers unmatched flexibility. The 380V industrial-grade build ensures reliability, making it one of the most future-proof investments in fiber processing today."

Marco Bellucci - Industrial Efficiency Advisor, EU Green Textiles Initiative

"In my assessment of energy-efficient textile machinery, the Tian Yuan machine exceeds expectations. With 30% lower energy consumption compared to manual systems and durable components that reduce replacement waste, it aligns strongly with circular economy principles. The Pro Model’s AI optimization not only boosts output but minimizes material loss—critical for sustainable scale-up."

Posted: 2 days ago

"Using the Advanced Model for R&D on high-tensile polyester. The smart sensors detect inconsistencies instantly. Setup was smooth, and the team adapted quickly. Already planning to order a second unit."

Posted: 1 week ago

"Switched from a competitor brand and immediately noticed better fiber alignment. The safety cover and easy maintenance save time and reduce risk. 10/10 would recommend."

Posted: 3 weeks ago

"The Base Model scaled perfectly with our growth. Only suggestion: include more video tutorials for first-time users. Otherwise, flawless performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.