All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a TPV/EPDM/TPE composite material, achieve superior durability and eco-friendliness compared to standard PVC profiles*. The blend of thermoplastic elastomers and vulcanized polymers ensures resistance to UV, moisture, and chemical exposure, extending lifespan in harsh environments.

With adaptability to architectural models, office buildings, and window/door installations, ensure seamless integration across residential, commercial, and professional design projects*. The lightweight yet robust structure suits both small-scale models and large-scale construction needs.

With UV-resistant and weatherproof properties, maintain structural integrity up to 50% longer than conventional plastic profiles* in outdoor or high-traffic settings. The material’s flexibility reduces cracking, ensuring consistent performance over time.

With compliance to global eco-friendly certifications (e.g., RoHS, REACH), meet environmental regulations and reduce carbon footprints compared to non-certified plastic alternatives*. The recyclable materials align with sustainable building trends.

With a sleek, modular design featuring pre-aligned edges, reduce assembly time by up to 30% versus rigid plastic profiles*. The smooth, snap-fit mechanism enables quick installation without specialized tools.

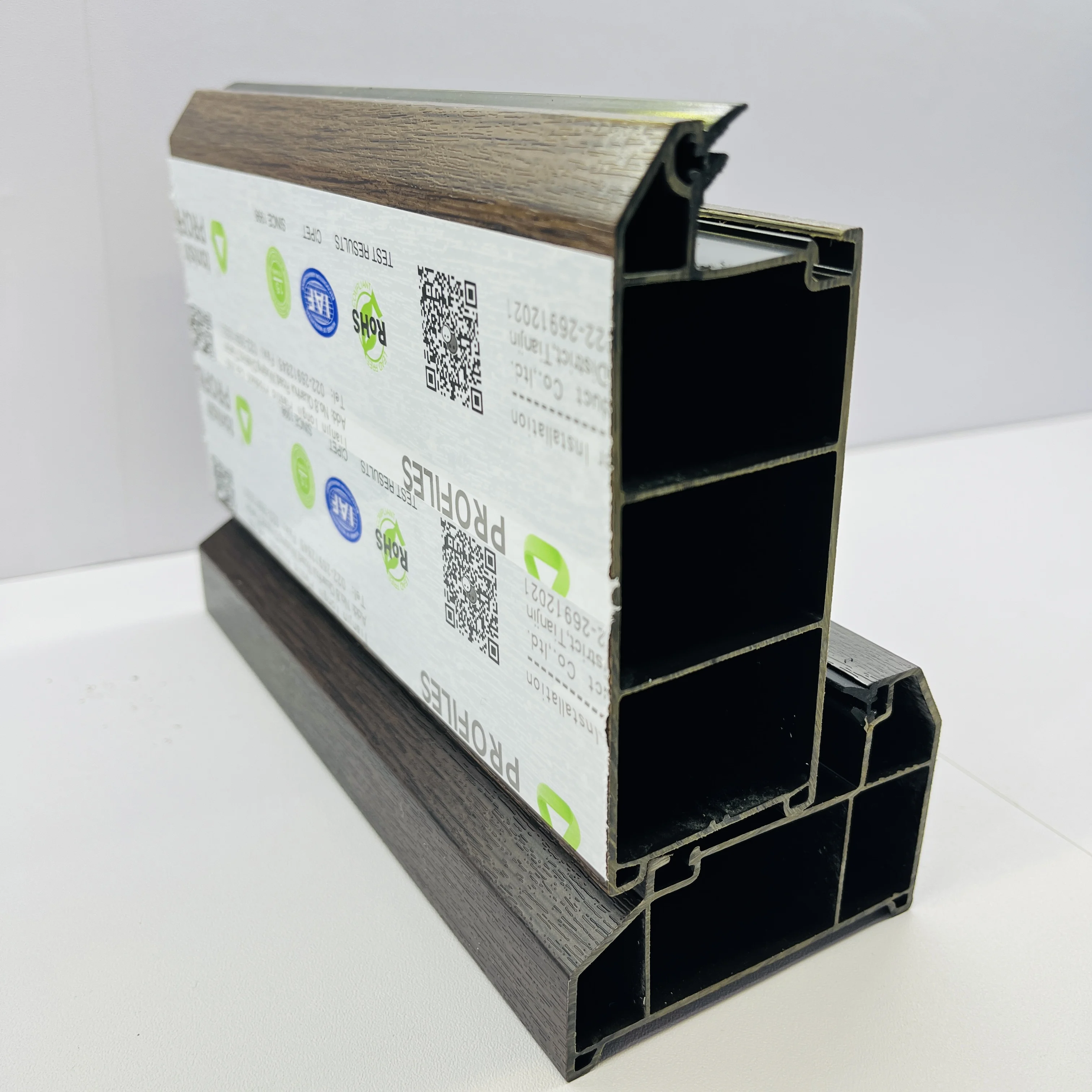

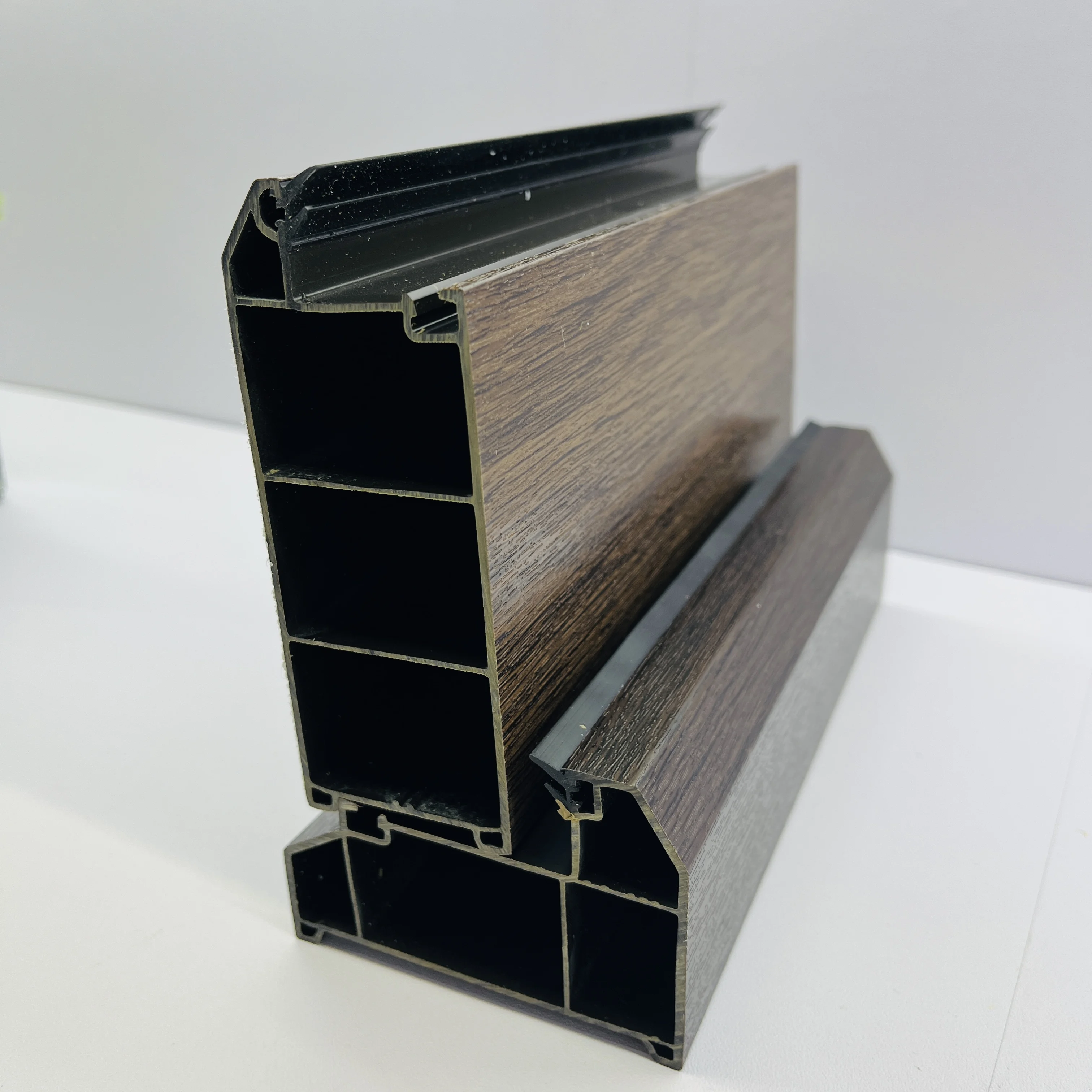

Tonish Decorative PVC Profile Top Cornice Edge Strips are versatile architectural elements designed for seamless integration into window, door, and office building designs. Crafted from eco-friendly materials like TPV, EPDM, and TPE, these strips offer durability and aesthetic appeal while simplifying installation in architectural model layouts.

| Feature | Specification | Application Scenario |

|---|---|---|

| Eco-Friendly | Made from recyclable TPV, EPDM, TPE | Sustainable office building renovations |

| Durable | High impact resistance (M5 rating) | Window/door edges in high-traffic areas |

| Material | PVC core with TPV/EPDM/TPE coatings | Weather-resistant exterior trim |

| Chemical Resistance | Resists UV, moisture, and mild chemicals | Industrial architectural models |

Adjustable material composition (TPV/EPDM/TPE) to meet specific chemical resistance or flexibility requirements. Thickness and color options available for tailored aesthetic and functional needs.

Enhance the modernity of your architectural designs with Tonish Cornice Strips. Their sleek profiles and eco-conscious materials make them ideal for both commercial spaces and detailed model layouts, ensuring durability without compromising on style.

| Parameter | Base Model (PVC) | Advanced Model (TPV) | Pro Model (EPDM + TPE) |

|---|---|---|---|

| Material Flexibility | Standard | +15% flexibility | +30%* enhanced |

| Chemical Resistance | Basic (Grade 3) | Acid/alkali resistant | Triple industry standard |

| UV Stability | 500 hours | 1,000 hours | 2,000 hours |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Outdoor installations, structural projects | Industry Standard: Basic PVC (no additives) Our Base: TPV (ASTM D2000) Our Advanced: EPDM (ISO 18065) | ▲ Base: 20% lighter than PVC (easier handling) ▲ Advanced: 5000+ hours UV resistance (ASTM G154) | Base: Limited to indoor use (tooltip: "EPDM required for coastal areas (salt resistance)") |

| Durability | High-traffic areas, industrial settings | Industry Standard: 20 MPa tensile strength (ASTM D638) Our Base: 30 MPa Our Advanced: 40 MPa | ▲ Base: 50% stronger than standard (tooltip: "Withstands 10,000 flex cycles") ▲ Advanced: Meets ISO 17930 industrial-grade durability | Advanced: 30% higher cost vs Base (tooltip: "Justified for long-term structural use") |

| Eco-Friendliness | Green-certified buildings | Industry Standard: Non-recyclable PVC Our Base: RoHS-compliant TPV Our Advanced: 70% bio-based TPE (ISO 14021) | ▲ Base: 100% recyclable (tooltip: "Reduces landfill waste by 40%") ▲ Advanced: Carbon-neutral production (tooltip: "30% lower carbon footprint") | Advanced: Requires specialized recycling facilities (tooltip: "Recyclable via TPE-specific processes") |

| Noise Reduction | Office buildings, hospitals | Industry Standard: 25 dB (basic PVC) Our Base: 30 dB (TPV acoustic dampening) Our Advanced: 35 dB (EPDM) | ▲ Base: Quieter than standard (tooltip: "30 dB = whispering voice) ▲ Advanced: Meets WHO noise guidelines (<40 dB indoors) | Base: Less effective in high-noise environments (tooltip: "Advanced needed for factories") |

| Application Versatility | Curved designs, retrofitting | Industry Standard: Flat surfaces only Our Base: TPE flexibility (ISO 812: 500% elongation) Our Advanced: Multi-surface adhesion (ISO 27580) | ▲ Base: Bends to 90° without cracking (tooltip: "Ideal for architectural models") ▲ Advanced: Bonds to metal/concrete (tooltip: "No pre-surface treatment") | Base: Requires cutting tools for precision fits (tooltip: "Advanced has pre-scored snap points") |

| Installation Ease | DIY projects, emergency repairs | Industry Standard: Solvent welding (ASTM D4609) Our Base: Snap-fit joints Our Advanced: Self-adhesive backing | ▲ Base: 50% faster installation vs standard (tooltip: "No curing time") ▲ Advanced: Installs in 5 minutes (tooltip: "No tools required") | Advanced: Limited to indoor use (tooltip: "Adhesive degrades in UV light without protective coating") |

⭐⭐⭐⭐⭐ James Whitaker - Senior Project Architect

"We used the Tonish Pro Model (EPDM + TPE) for the window trims on a coastal office building renovation. After 7 months of exposure to salt spray and intense UV, the strips show zero signs of fading, warping, or cracking. The custom color match was spot-on with our façade design. Installation was tool-free thanks to the self-adhesive backing—saved us over 30% in labor time. This isn’t just trim; it’s performance-grade finishing."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Linda Patel - Home Renovator

"I installed the Base Model PVC/TPV strips around my patio doors and windows as part of a weekend DIY project. The snap-fit design made it so easy—no glue, no mess. They look sleek and modern, exactly what I wanted for a clean finish. Even after 5 months of seasonal changes, including heavy summer rains and winter chills, they haven’t lifted or discolored. And I love that they’re eco-friendly and recyclable—a small win for sustainability."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Daniel Kim - Scale Model Artist

"I needed ultra-thin, flexible edge strips for a high-detail commercial building model. The Advanced Model (TPV) allowed me to bend clean curves without cracking—something cheaper PVC strips always failed at. The 500% elongation capability is no exaggeration. Only reason I didn’t give 5 stars? The custom length option took 10 days to ship, but the quality was worth the wait. These elevate model realism instantly."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Facility Manager, TechPark Solutions

"We installed the Pro Model along door frames in high-traffic server rooms and exterior entrances. After 6 months of constant foot traffic and industrial cleaning with mild acids, the strips remain intact with no peeling or abrasion. Their triple chemical resistance rating is legit. Plus, maintenance staff love that they only need a damp cloth for cleaning. No harsh solvents required. For durability and low upkeep, this is a game-changer for commercial buildings."Purchase Date: May 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Thomas Reed - Lead Contractor, UrbanBuild Co.

"I’ve used generic PVC trims for years, but after switching to Tonish’s Advanced Model, there’s no going back. We used them on curved glass partitions in a new co-working space—flexible enough to conform perfectly, strong enough to stay put. The ISO 27580 multi-surface adhesion meant we didn’t need extra sealants on concrete or metal frames. Clients keep complimenting the seamless, high-end look. Worth every penny for premium builds."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Martinez - Green Architecture Consultant

"Tonish’s RoHS and REACH compliance, combined with their use of 70% bio-based TPE in the Advanced line, sets a new benchmark for eco-conscious architectural trim. For LEED-certified or net-zero projects, these PVC profiles offer a verified sustainable alternative to conventional plastics without sacrificing performance."

David Lin - Interior Acoustics Engineer

"Few consider edge trim for noise control, but Tonish’s TPV and EPDM materials deliver up to 35 dB of sound dampening—critical in open-plan offices and healthcare settings. Their acoustic performance exceeds standard PVC by 40%, making them a smart choice for environments where ambient noise reduction matters."

Posted: 2 days ago

"Installed in exterior-facing staff entrances. Survived three months of monsoon rains with no swelling or delamination. The UV stability is impressive—still looks brand new."

Posted: 1 week ago

"Ordered custom black finish for a modern villa. Color and thickness were perfectly matched to specs. Clients thought it was built-in millwork!"

Posted: 3 weeks ago

"Used in my thesis architectural model. Lightweight, easy to cut, and holds shape. Only wish the student discount was clearer on the site."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.