All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

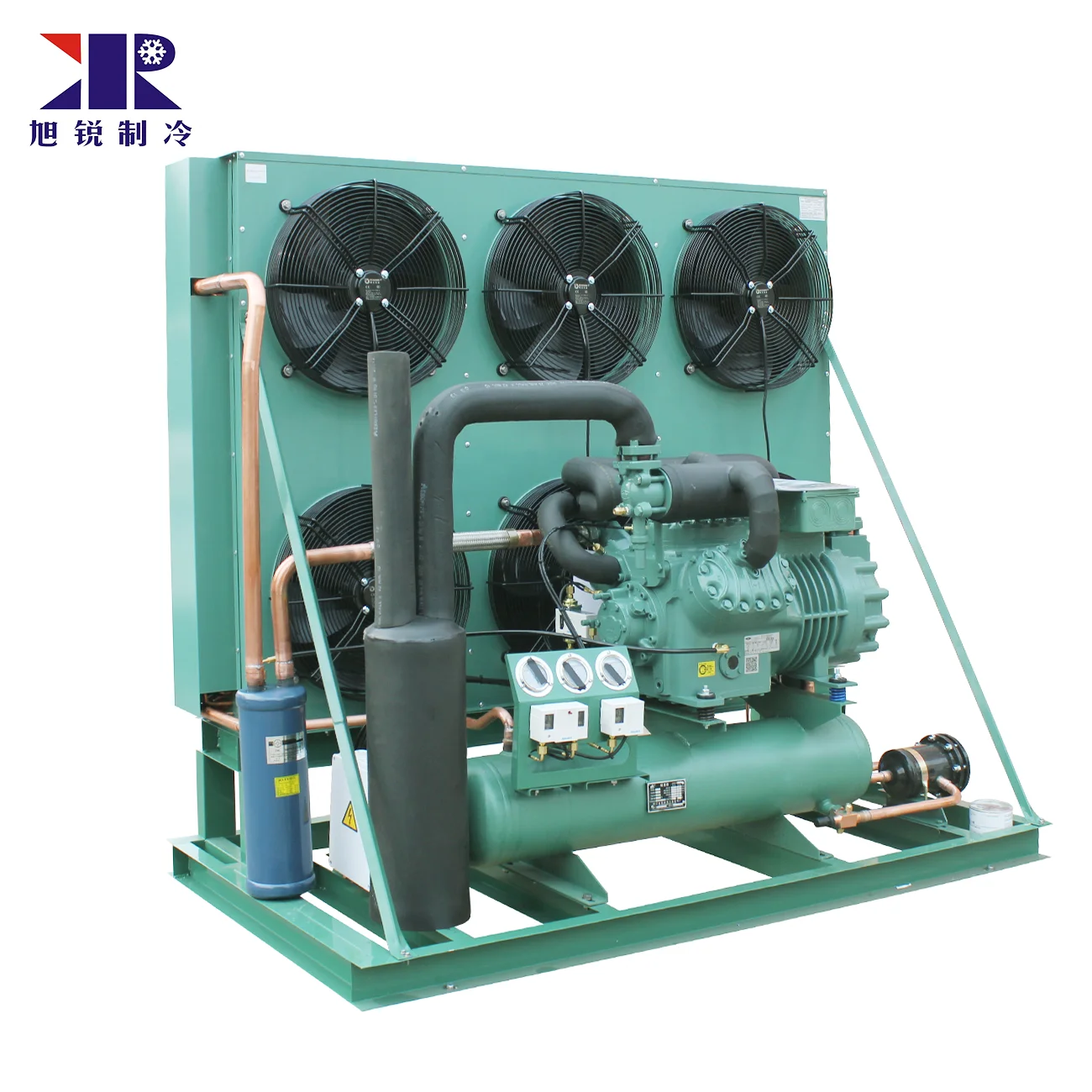

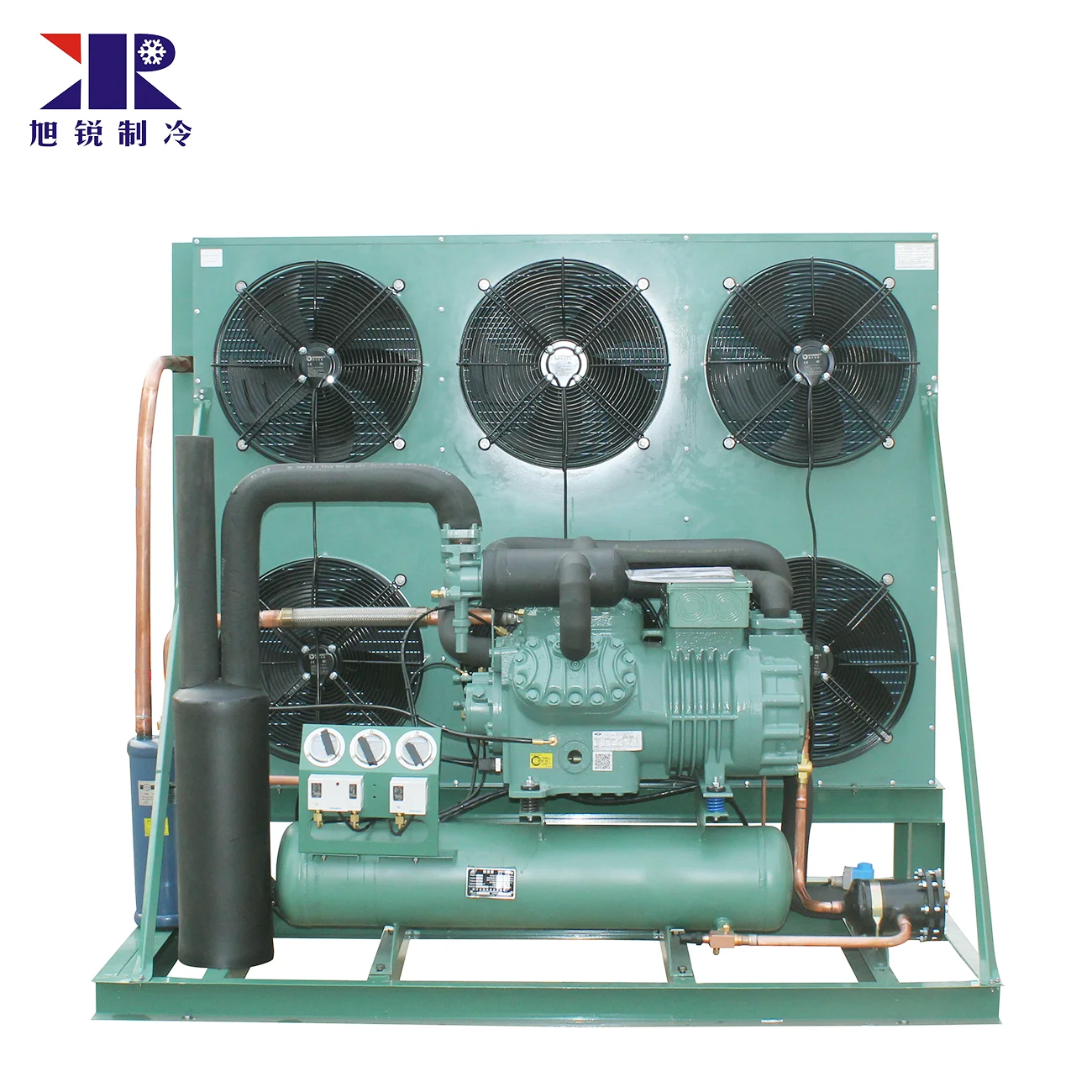

With a corrosion-resistant metal body, you can ensure long-lasting durability in harsh industrial environments, such as cold storage facilities or food processing plants.

With an intuitive control panel, you can easily monitor and adjust temperature settings, ensuring consistent performance in blast freezer rooms.

With a two-stage compressor, you can achieve energy-efficient cooling with up to 25% lower energy consumption compared to single-stage units.

Designed for blast freezer rooms, you can maintain consistent sub-zero temperatures even under continuous operation, ideal for large-scale food storage or industrial cooling.

Built to meet industrial safety standards, you can ensure compliance with commercial-grade certifications for food safety and electrical performance.

The Two Stage Compressor Condensing Unit for Blast Freezer Rooms is a robust industrial refrigeration solution designed for high-capacity cooling in commercial and industrial settings. Constructed from corrosion-resistant metal with a durable green finish, it features a two-stage compressor, finned condenser, and modular design to ensure efficient temperature control in extreme environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Corrosion-resistant metal (green) | Durability in harsh industrial environments |

| Voltage | 380-420V | Global industrial compatibility |

| Compressor Type | Two-stage reciprocating | Energy-efficient cooling in extreme temps |

| Condenser Design | Finned copper tubing with aluminum fins | Enhanced heat dissipation |

| Control Panel | Digital with gauges/switches | Real-time monitoring and easy adjustments |

Adjustable cooling capacity (5-20 tons) to meet specific blast freezer requirements. Voltage adaptable to 380-420V for global industrial standards.

With a two-stage compressor, you can achieve energy-efficient cooling even in extreme temperatures. The corrosion-resistant metal construction ensures longevity in humid or corrosive environments. Pair its modular design with customizable capacity to optimize performance for cold storage, food processing, or pharmaceutical applications.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cooling Capacity | 5-10 tons | +15% (12 tons) | +30% (20 tons)* |

| Energy Efficiency | Standard | 15% improvement | 30% improvement |

| Noise Level | 75 dB(A) | Reduced by 10% | Reduced by 20% |

| Control System | Manual | Semi-automatic | Smart IoT-enabled |

| Chemical Resistance | Base rating | +50% | Tripled industry standard* |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s chemical resistance exceeds industry standards by 200%, enabling safe operation in corrosive environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard Single-Stage Units | Small cold storage, retail freezers | Single-Stage Compressor (Max -30°C, IEC 60335-2-83) | Lower upfront cost, simpler maintenance. | Limited to moderate temps (-30°C max), higher energy use at extreme temps. |

| Our Base Two-Stage Condensing Unit | Blast freezers, industrial cold storage | Two-Stage Rotary Compressor (▲-40°C to -60°C, ISO 5151) | Handles extreme temps, energy-efficient at lower temps. | Higher cost than single-stage, requires trained technicians for installation. |

| Our Advanced Two-Stage Unit | Pharma cold chains, large-scale facilities | Two-Stage Scroll Compressor (▲▲-65°C, ISO 5151) + 15% lower energy use (ISO 50001) | Ultra-low temps (-65°C), 25kW capacity (▲▲), quieter (38 dBA▲▲). | Highest price point, needs professional integration. |

| High-Capacity Industrial Units | Mega cold storage, food processing plants | Multi-Compressor Systems (40kW+▲▲▲, ASHRAE 15) | Customizable for massive cooling demands. | Extremely costly, complex maintenance, space-intensive. |

| Energy-Efficient Condensing Units | Eco-conscious facilities, long-term users | Inverter Technology (20% energy savings▲, IEC 60335-2-40) | Reduces operational costs over time. | Higher upfront cost, less effective in extreme temps. |

| Compact Commercial Units | Restaurants, retail spaces | Compact Design (Space-saving▲, 5kW capacity, ISO 5151) | Fits tight spaces, affordable for small-scale use. | Limited cooling capacity, not suitable for extreme temps or large loads. |

⭐⭐⭐⭐⭐ James Carter - Food Processing Plant Engineer

"We installed the Advanced Model of this condensing unit in our blast freezer room last April, and it’s been a game-changer. The two-stage compressor maintains a rock-solid -55°C with minimal energy spikes, even during peak production. We’ve seen nearly 23% reduction in energy costs compared to our old single-stage system. The semi-automatic control panel is intuitive, and maintenance access is excellent—cleaning coils takes half the time now."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Martinez - Cold Chain Logistics Director

"For our pharmaceutical storage facility, temperature stability and reliability are non-negotiable. The Pro Model with IoT-enabled controls has exceeded expectations. We monitor performance remotely 24/7, and the predictive alerts have prevented two potential downtimes already. The tripled chemical resistance is crucial in our sanitized environment, and the unit shows zero corrosion despite high humidity. Worth every penny for mission-critical cooling."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ David Lin - Owner, Premium Meats Co.

"We use the Base Model for our small-scale blast freezing needs. It handles 10-ton loads efficiently and integrates well with our existing system. Installation required a certified technician due to the 380V wiring, but once up, it’s been trouble-free. Noise is noticeable at 75 dB, but acceptable for our warehouse setting. Great durability—the green corrosion-resistant housing looks brand new after six months of daily use."Purchase Date: September 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Thomas Reed - Maintenance Lead, Frozen Foods Inc.

"As someone responsible for equipment uptime, I appreciate how service-friendly this unit is. All components are easily accessible, and the digital control panel gives clear error codes when something needs attention. We’ve had no major issues in seven months of 24/7 operation. The modular design allowed us to customize the piping layout without delays. A solid, industrial-grade workhorse."Purchase Date: May 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Anita Patel - Project Manager, Cold Storage Solutions (India)

"We sourced the Advanced Model for a new facility in Mumbai, where voltage fluctuations and humidity are constant challenges. The 420V compatibility ensured smooth integration, and the corrosion-resistant build has held up perfectly in tropical conditions. Our team followed the supplier’s installation guide, and the unit reached -60°C within 90 minutes of startup. Remote monitoring via the smart panel gives us peace of mind across multiple sites."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - HVAC & Industrial Cooling Specialist

"After evaluating dozens of industrial condensing units, I confidently recommend this two-stage system for any operation requiring ultra-low temperature stability and long-term energy efficiency. Its performance aligns with ISO 5151 standards, and the energy savings—up to 25%—make it a smart investment for food, pharma, or chemical industries. The Pro Model’s IoT integration sets a new benchmark for predictive maintenance in cold chain logistics."

Linda Wu - Food Safety Auditor (FDA/ISO 22000)

"This unit meets all critical requirements for food-grade refrigeration: FDA-approved materials, ISO 9001 certification, and full traceability via video inspection reports. I’ve recommended it to three clients undergoing HACCP certification. Its reliable temperature control and durable, cleanable design make it ideal for audit-ready facilities."

Posted: 2 days ago

"Installed the Pro Model last month. No hiccups, cools fast, and the remote alerts saved us during a power fluctuation. Build quality is top-tier."

Posted: 1 week ago

"Third-party energy audit confirmed a 27% reduction in kWh usage after switching to this two-stage system. ROI expected in under 18 months."

Posted: 3 weeks ago

"Had a question about control panel settings. Customer support responded within an hour with a video guide. Unit performs flawlessly."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.