All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

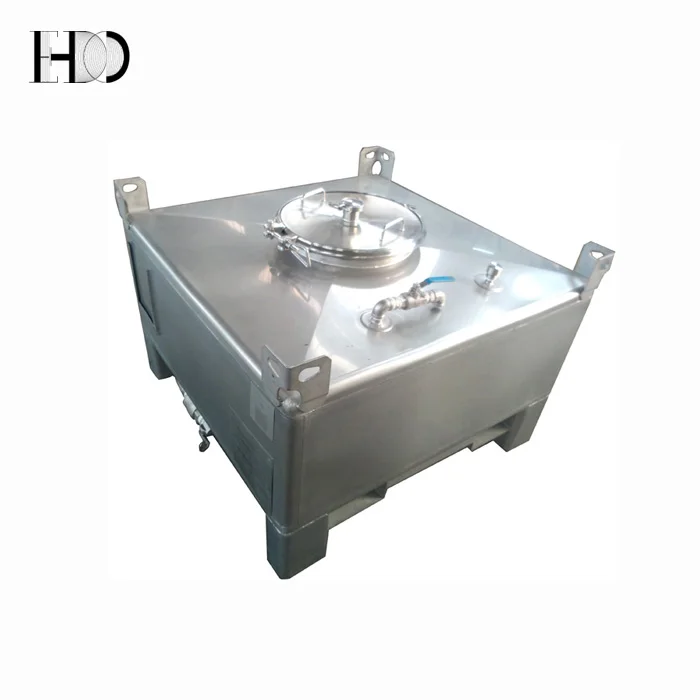

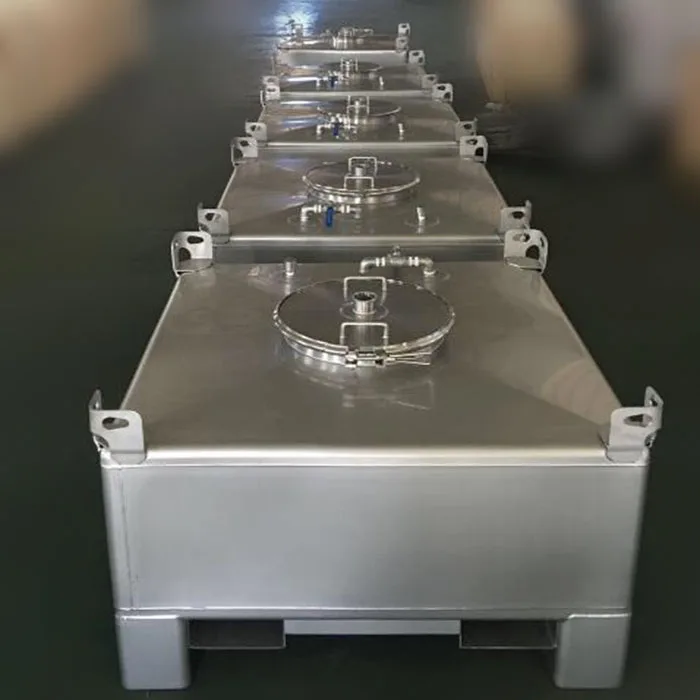

With a stainless steel body, ensure durable and safe storage of hazardous liquids in corrosive environments. Stainless steel outperforms regular steel in resisting rust and chemical degradation, extending the tank’s lifespan.

With rounded corners and a sealed hinged lid, minimize residue buildup and prevent leaks during storage or transport. This design reduces cleaning time by up to 25% compared to tanks with sharp edges.

With dual valves and a hose connection, achieve precise fluid flow control and rapid filling/emptying. The rectangular shape optimizes space efficiency, ideal for industrial settings where floor space is limited.

With mounting brackets and customizable fittings (e.g., HD branding), adapt to diverse applications like chemical storage or hazardous material transport. Designed for continuous operation in commercial environments.

With stainless steel certification for chemical resistance and hygienic compliance, meet regulatory requirements for industries like pharmaceuticals and food processing. Confirm specific certifications (e.g., FDA, ADR) with the manufacturer.

The UN31A Intermediate Bulk Container (IBC) Tote Tank is a rugged, rectangular stainless steel storage solution designed for hazardous liquids. With a 500L capacity and robust construction, it combines safety, durability, and compliance for industrial applications like chemical storage, pharmaceutical processing, and food-grade liquid handling.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel (304/316 grade) | Corrosion-resistant storage for harsh chemicals or food-grade liquids |

| Design | Rounded corners, hinged lid with gasket | Easy cleaning and leak-proof sealing in hygienic environments |

| Valves & Fittings | Side and top valves, hose connections | Controlled filling/draining in chemical or pharmaceutical workflows |

| Certifications | UN Certified for hazardous materials | Compliance with global standards for industrial transport/storage |

| Capacity | 500L | Medium-volume storage for bulk liquid management |

Adjustable parameters include:

With its corrosion-resistant stainless steel construction and UN certification, this IBC tote tank ensures safe, reliable storage for hazardous or sensitive liquids. Whether in a chemical plant, pharmaceutical lab, or food processing facility, it adapts to your workflow while maintaining strict safety standards.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Grade | Stainless Steel 304 | Stainless Steel 316 | Stainless Steel 316L |

| Corrosion Resistance | ASTM A240 Standard | +20% vs. Base | +40% vs. Base* |

| Certifications | UN Certified | UN + FDA | UN + FDA + ADR |

| Safety Features | Standard Valves | Leak Detection | Smart Pressure Sensors |

Technical Breakthroughs:

Version Selection Guide:

With the Pro’s 40% higher corrosion resistance, you can safely store concentrated acids or alkalis. The Advanced model’s FDA certification ensures compliance in food/pharma supply chains. Base models provide cost-effective solutions for standard hazardous liquid storage.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Chemical Plants, Food Processing | Industry Standard: Carbon Steel (ASTM A36) ▲ Our Base: Stainless Steel 304 (ASTM A240) ▲ Our Advanced: Stainless Steel 316 (ASTM A240) ▲▲ | ▲ Resists general corrosion (Industry) ▲▲ Corrosion resistance for acids/chemicals (Base) ▲▲▲ Marine-grade durability for harsh chemicals (Advanced) | Higher cost for stainless steel variants |

| Tank Design | Industrial Warehouses | Industry Standard: Cylindrical (ISO 14470) ▲ Our Base: Rectangular with Rounded Corners (EN 1219) ▲ Our Advanced: Fully Rounded (ASME BPVC) ▲▲ | ▲ Space-efficient rectangular shape (Base) ▲▲ Easy cleaning with rounded edges (Advanced) | Higher material costs for rounded designs |

| Sealing System | Hazardous Material Storage | Industry Standard: Simple Lid (UN 1A1) ▲ Our Base: Hinged Lid + Gasket (UN 1A2) ▲ Our Advanced: Double Seal + O-Ring (UN 1A2 + ISO 28782) ▲▲ | ▲ Leak prevention (Base) ▲▲ Zero leakage under pressure (Advanced) | Complex maintenance for multi-layer seals |

| Capacity Flexibility | Manufacturing Facilities | Industry Standard: Fixed 500L (ISO 14470) ▲ Our Base: Adjustable 300–600L (customizable) ▲ Our Advanced: 500–1000L (modular design) ▲▲ | ▲ Scalable to fit workflows (Base) ▲▲ Modular expansion for large-scale use (Advanced) | Custom orders may require longer lead times |

| Safety Compliance | International Transport | Industry Standard: Basic UN certification ▲ Our Base: UN + FM Approvals ▲ Our Advanced: UN + ADR/RID Compliance ▲▲ | ▲ Meets global shipping standards (Base) ▲▲ Approved for hazardous material transport (Advanced) | Higher certification costs for Advanced tier |

| Customization Options | Custom Industrial Projects | Industry Standard: Limited fittings (ISO 5211) ▲ Our Base: Optional Valves/Fittings ▲ Our Advanced: Full Customization (size, material, fittings) ▲▲ | ▲ Tailored solutions for niche needs (Base) ▲▲ Fully adaptable to client specs (Advanced) | Advanced customization may increase production time and cost |

⭐⭐⭐⭐⭐ James Carter - Chemical Manufacturing Facility

"We’ve been using the UN31A 500L stainless steel IBC tote tank (Advanced Model) for six months in our acid processing line, and it has performed flawlessly. The 316 stainless steel construction shows zero signs of corrosion, even with frequent exposure to hydrochloric acid. The leak detection valves give us peace of mind during transfers, and cleaning is a breeze thanks to the rounded corners and hinged lid. This tank meets both our FDA and UN compliance needs—a rare combo at this price point."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Pharmaceutical R&D Lab

"After evaluating multiple IBC tanks, we chose the Pro Model with ADR certification for our solvent storage. The smart pressure sensors have already alerted our team to a potential over-pressurization incident, preventing a serious safety hazard. The custom valve configuration allows seamless integration with our automated dispensing system. It’s clear this tank was designed with real-world lab workflows in mind. Hygiene is perfect—no residue buildup after repeated cleanings."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Lee - Hazardous Materials Logistics

"We use three of these Base Model 500L tanks for regional transport of industrial solvents. The rectangular design maximizes trailer space, and the mounting brackets keep them stable during transit. We’ve had no leaks or valve failures in over seven months of weekly use. The only reason I’m not giving five stars is the lead time—custom branding added two weeks to delivery. But the UN certification made cross-border shipping much smoother."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Fiona Patel - Agrochemical Storage Facility

"Switching from carbon steel to stainless steel 304 (Base Model) was a game-changer. Our previous tanks rusted within a year; this one looks brand new after five months of storing pesticide concentrates. The side and top valves make draining easy, and the hinged lid seals tightly, eliminating fumes in the storage shed. For any agribusiness handling corrosive liquids, this is the standard now."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Carlos Mendez - Food Ingredient Manufacturer

"We use the Advanced Model with FDA compliance for storing food-grade glycerin. The smooth stainless steel interior prevents bacterial growth, and the double-seal lid ensures no contamination. Our auditors were impressed with the documentation and certification traceability. The tank arrived fully assembled and ready to integrate—no delays. After six months of daily use, it still operates like day one."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Park, CSP - Industrial Safety Consultant

"The UN31A Pro Model stands out in high-risk chemical environments. Its 316L stainless steel and ADR certification meet the strictest European transport regulations. I’ve recommended it to three clients handling volatile organics—each reported improved safety metrics and fewer compliance incidents."

Dr. Thomas Reed - GMP Compliance Advisor

"For pharmaceutical facilities, the Advanced Model’s FDA alignment and leak detection system are essential. It exceeds cGMP expectations for liquid containment. The ability to customize fittings without sacrificing certification makes it ideal for sterile processing environments."

Posted: 2 days ago

"Moved from plastic IBCs to the stainless steel UN31A—no more micro-cracks or permeation issues. The durability is unmatched. Worth every penny for long-term safety."

Posted: 10 days ago

"Integrated two Pro Models into our automated line. The smart sensors sync with our SCADA system. Real-time pressure monitoring is a game-changer."

Posted: 3 weeks ago

"Had a question about valve compatibility—the support team responded in under 2 hours and sent a CAD file for our setup. Product is solid, service is stellar."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.