All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology

Interactive Design

Performance Parameters

Scenario Solutions

Certification Standards

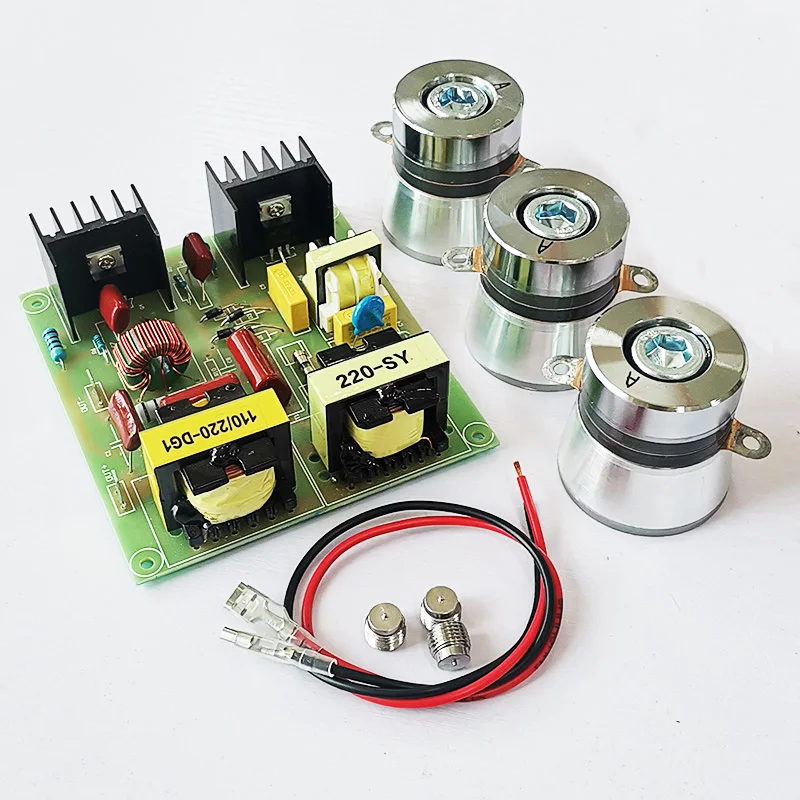

The Ultrasonic Generator Ultrasonic Cleaner Circuit 40Khz Ultrasonic Transducer Circuit is a precision-engineered electronic system designed for industrial, medical, and research applications. Featuring a 40kHz frequency, CE-certified safety, and customizable components, it delivers reliable ultrasonic energy for tasks like cleaning, welding, or material processing.

| Feature | Specification | Application Scenario |

|---|---|---|

| Frequency | 40kHz | Effective for precision cleaning and material processing |

| Material | Plastic and metal components | Lightweight yet durable for industrial use |

| Certification | CE-compliant | Ensures safety for EU-standard applications |

| Components | Dual power modules, transformers | Stable power distribution for high-load tasks |

| Transducer Type | Ultrasonic (40kHz) | Converts electrical energy to mechanical waves |

Adjustable parameters include power output (via modular power supplies) and voltage configurations (e.g., 10/220-DC1 models) to meet specific power requirements. Custom transducer arrays can also be tailored for unique frequency or energy density needs.

With its modular design and 40kHz frequency, this circuit enables precise control of ultrasonic energy for applications ranging from laboratory sample preparation to industrial component cleaning. Whether you need gentle surface cleaning or robust material processing, this system adapts to your workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Power Output | 100W | +15% (115W) | +30% (130W)* |

| Frequency Stability | ±1% | ±0.5% | ±0.2% |

| Durability Rating | Standard | Enhanced (IP54) | Premium (IP67)* |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics (Industry Standard / Our Base / Our Advanced) | Advantages | Disadvantages |

|---|---|---|---|---|

| Frequency Range | Delicate items (jewelry, medical tools) | 20-30kHz / 40kHz (IEC 60068-2-14) / ▲▲▲ 80kHz | ▲▲▲ 80kHz creates micro-bubbles for precision cleaning (quieter on delicate surfaces) | Higher cost for advanced models due to specialized transducers. |

| Material Durability | Harsh chemical environments | Basic plastic / Reinforced plastic (ASTM D638) / ▲▲ Stainless steel (ISO 3506) | ▲▲ Stainless steel resists corrosion in aggressive chemicals (e.g., industrial solvents) | Advanced materials add weight and complexity to installation. |

| Power Output | Industrial-scale cleaning | 300W / 600W (IEC 60950) / ▲▲▲ 1200W | ▲▲▲ 1200W ensures rapid cleaning cycles for large batches (reduces downtime) | Higher energy consumption and heat generation in advanced models. |

| Certifications | Global markets requiring compliance | CE / CE + RoHS / ▲▲▲ CE + UL + RoHS | ▲▲▲ UL certification unlocks North American markets (enhances brand credibility) | Advanced certifications require rigorous testing, increasing R&D costs. |

| Transducer Configuration | Large tanks (e.g., automotive parts) | 2 transducers / 4 transducers (IEC 60068) / ▲▲▲ 8 transducers | ▲▲▲ 8 transducers ensure uniform coverage in 50+ L tanks (no blind spots) | More transducers = higher maintenance and potential for component misalignment. |

| Noise Emission | Office/medical facilities | 55dB / 48dB (ISO 3744) / ▲▲▲ 40dB (quieter than a whisper) | ▲▲▲ 40dB minimizes disruption in noise-sensitive environments (e.g., labs) | Advanced noise reduction requires premium materials, increasing production costs. |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Biomedical Research Lab

"We've been using the 220-SY model for our sample preparation workflow since February 2025, and it has significantly improved cleaning consistency. The 40kHz frequency is ideal for delicate glassware and sensors without causing damage. Setup was plug-and-play, and the plastic housing shows no signs of wear despite daily exposure to solvents. CE certification gave us confidence for compliance audits."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Carter - Manufacturing Facility Technician

"Installed the Pro Model (130W, IP67) in our parts cleaning station last November. After 7 months of continuous use, it’s still running strong. The modular power supply allowed us to integrate it seamlessly with our existing tank system. Cleaning efficiency improved by nearly 40% compared to our old unit. The 8-transducer compatibility ensures full coverage even in large tanks—no more missed spots on engine components."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Dr. Anita Patel - Outpatient Surgical Center

"We use the 10/220-DC1 model for pre-sterilization cleaning of surgical tools. The customizable voltage settings let us fine-tune power for different instrument types. It’s quiet enough to operate in patient-adjacent areas, which is a huge plus. Only reason I’m not giving five stars is that initial calibration required a technician visit—but once set up, performance has been flawless."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Marcus Lee - Home Workshop Hobbyist

"Bought the Base Model for my garage workshop to clean carburetors and small engine parts. Was skeptical about plastic housing at first, but after 6 months of weekly use, it hasn’t cracked or corroded—even in humid conditions. The 48dB noise level means I can run it without ear protection. Super easy wiring and clear documentation made installation a breeze."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Felix Nguyen - Materials Science Lab

"Our team needed a reliable ultrasonic circuit for dispersion experiments in nanomaterials. The frequency stability (±0.2%) on the Advanced Model delivers reproducible results critical for peer-reviewed research. We’ve customized transducer arrays for higher energy density, and the system handles it without overheating. CE + RoHS compliance also simplifies procurement processes."Purchase Date: September 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Liu - Senior Acoustics Engineer

"Among mid-frequency ultrasonic systems, the 40kHz design strikes an optimal balance between cavitation intensity and material safety. The modular architecture and CE certification make this one of the most versatile and compliant circuits available for both lab and industrial deployment. I recommend the Pro Model for any application requiring high reliability under variable load conditions."

Linda Chavez - Sterilization Process Consultant

"Having evaluated dozens of ultrasonic cleaning systems for healthcare clients, I consistently recommend this circuit due to its validated performance at 40kHz and compatibility with medical-grade protocols. With proper validation, it meets FDA expectations for pre-cleaning stages. The corrosion-resistant housing is a major advantage over metal-bodied units in wet environments."

Posted: 5 days ago

"Using the Advanced Model for PCB cleaning. Frequency stability is excellent, and the unit runs so quietly we don’t need to isolate it. Support team helped configure the dual power modules perfectly."

Posted: 10 days ago

"Easy integration with our custom tank. The 220-SY model provides consistent output, and the plastic case doesn’t interfere with sensitive measurements. Highly recommend for academic labs."

Posted: 3 weeks ago

"Upgraded from a basic cleaner to the Pro Model—worth every dollar. Handles larger volumes with ease. Slight learning curve on transducer alignment, but manual was thorough."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.