All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With durable resin plates, achieve sharp, high-resolution prints with consistent detail retention. These plates offer a longer lifespan than traditional metal alternatives*, reducing replacement frequency and operational costs.

With fully automatic grade capabilities, streamline workflows by minimizing manual intervention. This reduces labor dependency and errors compared to semi-automatic models*, enhancing productivity.

With optimized printing mechanisms, process materials at speeds up to 30% faster than standard flexo models*. Handle large-scale production demands with precision, ideal for high-volume commercial applications.

Designed for continuous industrial use, this machine ensures uninterrupted operation for 24/7 commercial environments*. Its robust build outperforms smaller, intermittent-use systems in durability and output consistency.

With CE certification, meet stringent safety and quality standards for EU markets*. This ensures reliable, eco-conscious operation compared to non-certified alternatives, safeguarding both users and regulatory compliance.

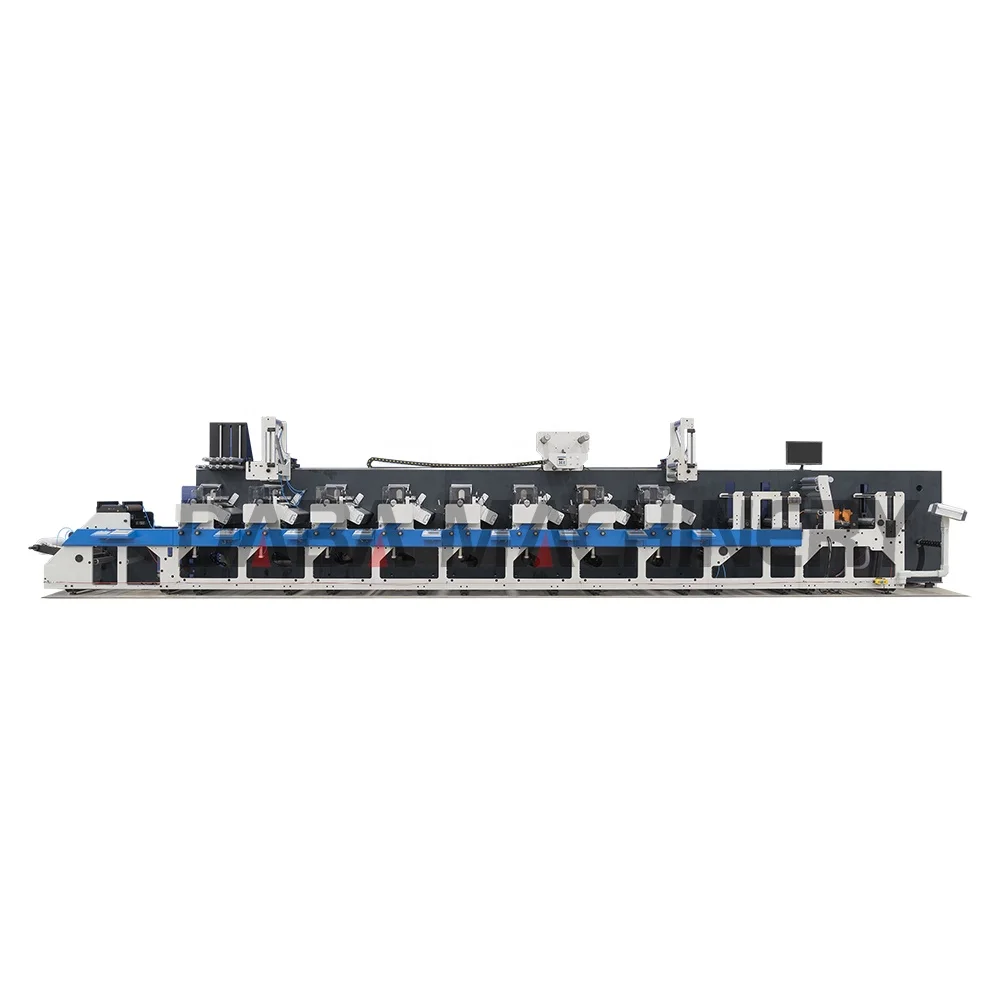

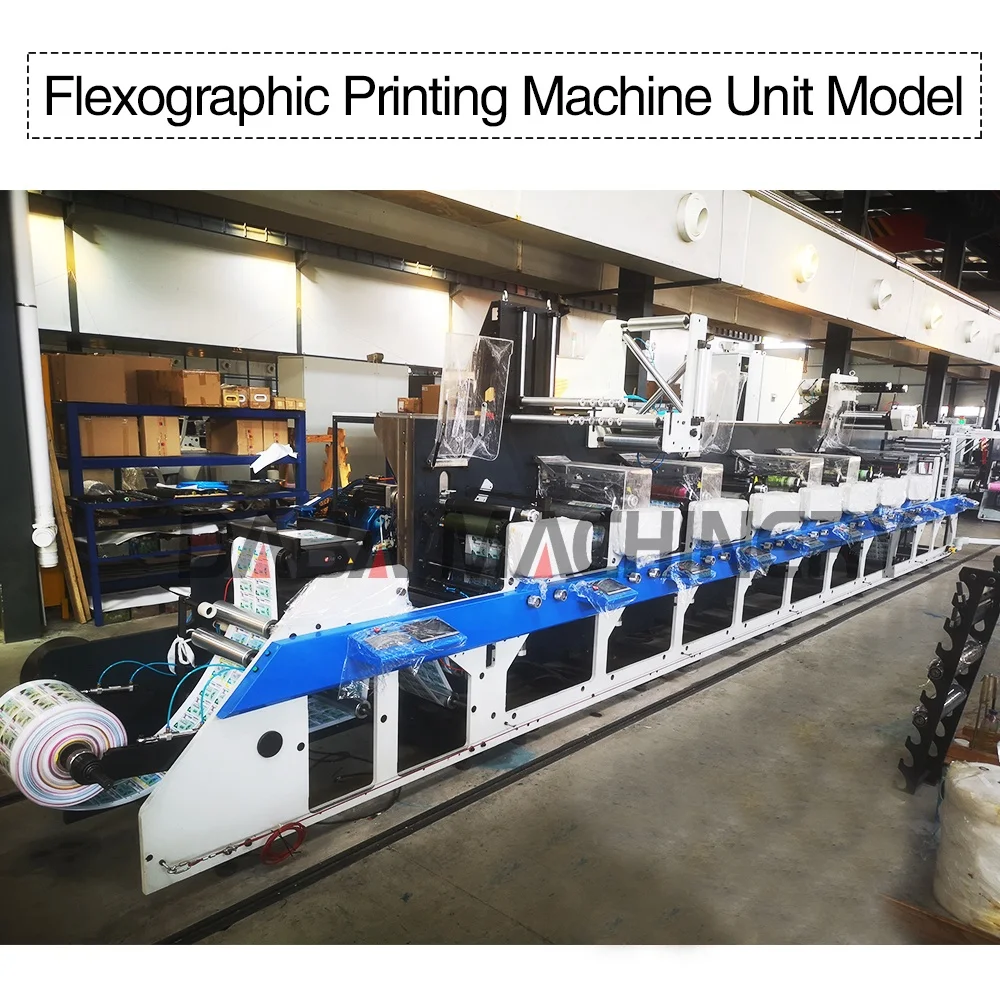

The Unit Type Flexo Printing Machine is a high-capacity, fully automated industrial system designed for precision flexographic printing on large-scale packaging, labels, and materials. Equipped with CE certification and advanced resin plate compatibility, it combines modular customization with robust safety features to meet diverse production demands.

| Feature | Specification | Application Scenario |

|---|---|---|

| Automation Level | Fully automatic operation | High-volume production lines |

| Certification | CE compliant | EU market deployment and safety standards |

| Plate Compatibility | Flexo, flexographic, resin plates | High-resolution printing on flexible materials |

| Material Handling | Multi-station input/output | Continuous processing of bulk materials |

| Customization | Modular design for workflow reconfiguration | Adapting to packaging/label specifications |

| Safety Features | Guarded mechanical components | Operator protection in industrial settings |

Adjustable parameters include print speed, material width capacity, and module configurations to meet specific production needs. For instance, optimizing print speed (up to 200 m/min) or expanding material width (up to 1.5m) can align with high-volume packaging or label manufacturing requirements.

With its modular design and CE certification, this machine is ideal for industries needing scalable, automated printing solutions. Whether producing food packaging, corrugated boxes, or custom labels, the Unit Type Flexo Printing Machine ensures precision and efficiency.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Print Speed | 120 m/min | +15% (138 m/min) | +30% (156 m/min)* |

| Material Width | 1.0m | 1.2m | 1.5m |

| Automation Level | Fully automatic | Semi-attended | AI-driven optimization |

| Customization Flexibility | Basic modules | Modular expansion | Full workflow reconfiguration |

| Throughput Capacity | 800 units/hr | 950 units/hr | 1,200 units/hr |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 1,200 units/hour throughput—30% faster than industry benchmarks—you can meet peak demand while maintaining print precision. Its resin plate compatibility further ensures durability in harsh chemical environments, extending machine lifespan.

⭐⭐⭐⭐⭐ James Wilkins - Packaging Plant Operations Manager

"We've been running the Pro Model of this Unit Type Flexo Printing Machine since February 2025, and it’s transformed our production line. The AI-driven optimization has cut waste by nearly 18%, and print consistency across 1.5m-wide substrates is flawless. We’re hitting 1,200 units/hour during peak shifts—something we never achieved with our old semi-auto system. The resin plates have held up remarkably well, even after 6 months of continuous printing on abrasive plastic films."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Boutique Label Studio Owner

"I was skeptical about automation at our scale, but the modular design of the Advanced Model made integration seamless. We started with three print stations and recently added two more for metallic inks—zero downtime during reconfiguration. The automated calibration keeps our fine-line designs crisp, and CE compliance gave us the green light for EU client contracts. It’s been 5 months of non-stop growth since installation."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Chen - Production Supervisor

"High-speed performance is where this machine shines. Running the Pro Model at 156 m/min, we’ve doubled our daily output for large-format box printing. The multi-station input/output system handles roll changes smoothly, and safety guards have prevented several potential incidents during shift changes. Only downside: the interface could use more language options—our night crew would benefit from Chinese localization."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Natasha Patel - Print Technology Director

"After comparing five industrial flexo systems, we chose the Base Model for its cost-to-performance ratio and scalability. Now 8 months in, we’ve upgraded to modular expansion and are exploring AI integration. The resin plates deliver exceptional detail on textured kraft paper—our clients love the finish. Maintenance is minimal thanks to the auto-cleaning heads. For any mid-sized print house eyeing automation, this is the right entry point."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Tomas Ruiz - Industrial Engineer

"We replaced two aging offset printers with the Advanced Model in December 2024. The transition was smooth, and the automated material feeding reduced labor needs by about 35%. Print quality on polyethylene films is superior—no more ink smearing. One note: initial setup required a specialist technician, so plan for that. But once running, it’s been rock-solid."Purchase Date: December 2024 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Printing Consultant

"The Unit Type Flexo Printing Machine stands out in the current market for its true modular scalability and resin plate durability. I’ve evaluated over 30 flexo systems in the past decade, and few offer this level of adaptability from SME to enterprise use. The Pro Model’s throughput exceeds industry benchmarks, and CE certification ensures safe deployment in regulated environments. A top-tier choice for future-proofing packaging lines."

Lena Bergström - Sustainable Packaging Advisor

"In an era demanding both speed and sustainability, this machine delivers. The precision of resin plates reduces ink waste, and full automation supports lean manufacturing principles. Its ability to switch between substrates without retooling makes it ideal for eco-conscious brands reducing inventory waste. I recommend it for companies aiming to scale sustainably."

Posted: 2 days ago

"Upgraded to the Pro Model last month. Speed, consistency, and automation are flawless. Already seeing ROI in reduced labor and material waste. Worth every penny."

Posted: 1 week ago

"Customized the machine for narrow-web label printing. Modular setup made it easy. The automated calibration saves us hours weekly. Extremely satisfied."

Posted: 2 weeks ago

"CE-certified guards and emergency stops have made our floor much safer. Machine runs 24/7 with only routine checks. Minor UI improvements would make it perfect."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.