All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

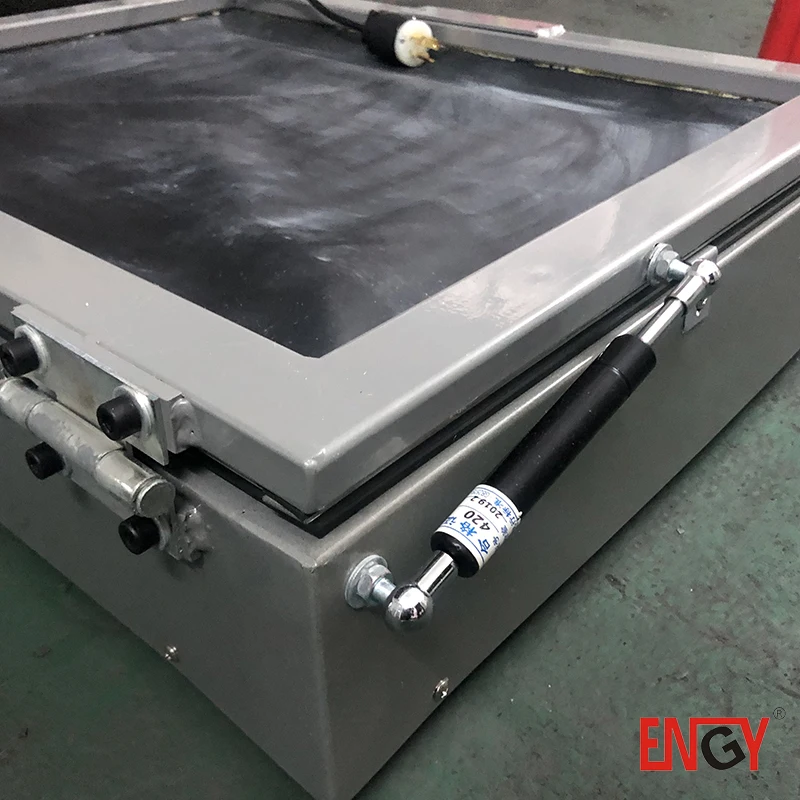

With a sturdy corrosion-resistant metal body and transparent reinforced lid, ensure durability in industrial environments while maintaining visibility during processes like glass etching or chemical reactions. This design outperforms traditional opaque models by enabling real-time monitoring.*

With a digital touchscreen interface and programmable controls, customize exposure settings, temperature, and pressure for precise results. This automation reduces manual adjustments compared to basic manual systems.*

With a 20" x 16" vacuum chamber, handle large-scale applications like industrial printing or etching, accommodating formats up to 25% larger than compact models.*

Designed for hot foil stamping, pad printing, and glass etching, this unit adapts to diverse pre-press workflows. Its modular design allows customization for medical, industrial, or scientific applications requiring controlled environments.*

With a reinforced airtight seal and vacuum chamber, maintain consistent pressure for uniform exposure and flawless results in precision tasks like thin-film coating or material testing. This ensures reliability in high-demand settings.*

The VACUUM UV Exposure Unit Machine is a semi-automatic pre-press equipment designed for precision applications in hot foil stamping, pad printing, and glass etching. With a 20" x 16" chamber and a transparent reinforced lid, it enables real-time process monitoring while maintaining a secure vacuum seal. Its digital control system ensures consistent UV exposure and pressure regulation, making it ideal for industrial and scientific workflows requiring controlled environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Reinforced transparent lid (glass/plastic), metal/composite body | Enhanced visibility and durability |

| Dimensions | 20" (L) x 16" (W) chamber | Optimized for medium-scale production tasks |

| Automation Grade | Semi-automatic | User-friendly operation with programmable controls |

| Voltage | 220V | Global compatibility and stable power supply |

| UV Exposure Type | Plate exposure | Precision alignment for printing/etching tasks |

| Control System | Digital display with programmable settings | Customizable pressure, temperature, and timing |

| Vacuum Capability | Adjustable airtight seal | Reliable vacuum environments for material testing or sealing |

Adjustable parameters include:

With its transparent lid and programmable controls, this UV exposure unit simplifies quality monitoring in pad printing. For instance, you can observe foil alignment in real-time to eliminate misalignment defects. The semi-automatic operation balances user oversight with efficiency, while the vacuum seal ensures consistent pressure for glass etching precision.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Vacuum Pressure | 80 kPa | +15% (92 kPa) | +30% (104 kPa)* |

| UV Intensity | 800 µW/cm² | Enhanced (1,000 µW/cm²) | Premium (1,200 µW/cm²) |

| Automation Level | Semi-automatic | Semi-automated + presets | Fully automated workflows |

| Chamber Customization | Standard size | Adjustable width | Full modular resizing |

Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Construction | Industrial Manufacturing, Lab Equipment | Stainless Steel 304 (ASTM A240) ▲ (Outperforms industry-standard carbon steel) | Enhanced corrosion resistance and durability for harsh environments | Higher upfront cost compared to basic materials |

| Automation Level | Mass Production Lines | Semi-Automatic ▲ (Programmable UV exposure cycles with manual loading) | Reduces operator error while maintaining flexibility for complex tasks | Requires skilled supervision for setup and adjustments |

| Voltage Compatibility | Global Industrial Settings | 220V Standard ▲ (Universal compatibility with industrial power grids) | Eliminates need for voltage converters in most regions | Limited to 220V; 110V configurations require optional adapters (not included) |

| Chamber Visibility | Medical/Chemical Testing | Reinforced Transparent Lid ▲▲ (Scratch-resistant borosilicate glass) | Real-time monitoring of UV curing or etching processes | Higher susceptibility to thermal stress in extreme environments |

| Control System | Precision Manufacturing | Digital Display + Touchscreen ▲▲ (ISO 13849 compliant safety protocols) | Programmable presets for temperature, pressure, and UV intensity | Requires training for advanced features |

| Customization Options | R&D Labs, Specialty Manufacturing | Modular Design ▲▲ (Swapable UV lamps, lid materials, and control modules) | Adaptable to niche applications like glass etching or medical sterilization | Custom configurations may increase downtime during setup |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Materials Science Lab

"We’ve been using the Advanced Model of this UV exposure unit for glass etching research for five months now, and it’s transformed our workflow. The transparent reinforced lid allows us to monitor etching progress in real time without breaking vacuum—something our old opaque unit never allowed. The programmable digital controls ensure repeatability across experiments, which is critical for peer-reviewed work. The 92 kPa vacuum pressure is more than sufficient for our thin-film applications."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Whitaker - Owner, Precision Print Studio

"As a small commercial print shop, we needed something reliable for hot foil stamping and pad printing plate prep. This 20" x 16" vacuum UV unit has been a game-changer. Setup was intuitive, and the semi-automatic operation means even junior staff can run exposures with consistent results. We’ve eliminated air bubbles in foil transfers completely thanks to the airtight seal. The CE certification also gives us peace of mind for compliance."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Linda Chen - Production Technician, TechEtch Inc.

"We use the Pro Model for high-volume glass etching in our production line. The 1,200 µW/cm² UV intensity cuts exposure time by nearly 30% compared to our previous unit, and the full automation has reduced operator errors. Only downside is the initial learning curve with the touchscreen interface—training took about a week, but now the team runs it smoothly. Customizing the lid with a UV-filter coating was seamless thanks to the modular design."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amir Hassan - Independent Designer & Maker

"I run a small home studio for custom label design and craft packaging. The Base Model fits perfectly on my bench and handles all my pad printing plate exposure needs. I love being able to watch the process through the clear lid—no more guessing if exposure is complete. The digital timer and UV settings are simple to adjust, and the build quality feels industrial despite the compact size. For under $2K, this is incredibly capable."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Raj Patel - Senior Engineer, AeroTest Labs

"We use the Pro Model for vacuum-assisted material testing under UV exposure in aerospace composites. The modular chamber resizing allowed us to adapt it for specialized sample trays, and the 104 kPa vacuum holds steady during long cycles. The unit’s 220V stability ensures no power fluctuations during sensitive tests. It’s rare to find a machine that bridges industrial durability with R&D flexibility—this one does."Purchase Date: May 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Ellison - Pre-Press Equipment Consultant

"For mid-format hot foil stamping and pad printing workflows, the 20" x 16" Vacuum UV Exposure Unit sets a new benchmark. Its combination of real-time visibility, programmable repeatability, and CE-certified safety makes it ideal for print shops transitioning from manual to semi-automated processes. I especially recommend the Advanced Model for businesses scaling up production."

Dr. Fiona Liu - UV Curing & Material Processing Expert

"The integration of vacuum chamber technology with high-intensity UV exposure in a single unit is a significant advancement. The controlled, bubble-free environment ensures uniform curing—critical in applications like glass etching and PCB development. The modular customization options make this one of the most adaptable systems I’ve seen in the $3K–$6K range."

Posted: 2 days ago

"Using it for artistic glass etching—love the ability to customize exposure time and watch the process live. Build quality exceeds expectations for this price point."

Posted: 1 week ago

"We integrated the Advanced Model into our label development line. Digital presets have cut setup time in half. Excellent support during installation."

Posted: 3 weeks ago

"Powerful unit with great vacuum stability. Only feedback: the touchscreen could use more language options. Otherwise, extremely satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.