All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, ensure durable and hygienic performance in high-humidity or chemical-exposed environments*. This material choice outperforms traditional carbon steel models prone to rust, ideal for food processing and pharmaceutical applications.

With an intuitive touchscreen interface and pre-programmed sorting criteria (e.g., size, weight), customize workflows 50% faster than manual setups*. Streamline operations for fruits, vegetables, or corn without reconfiguring hardware.

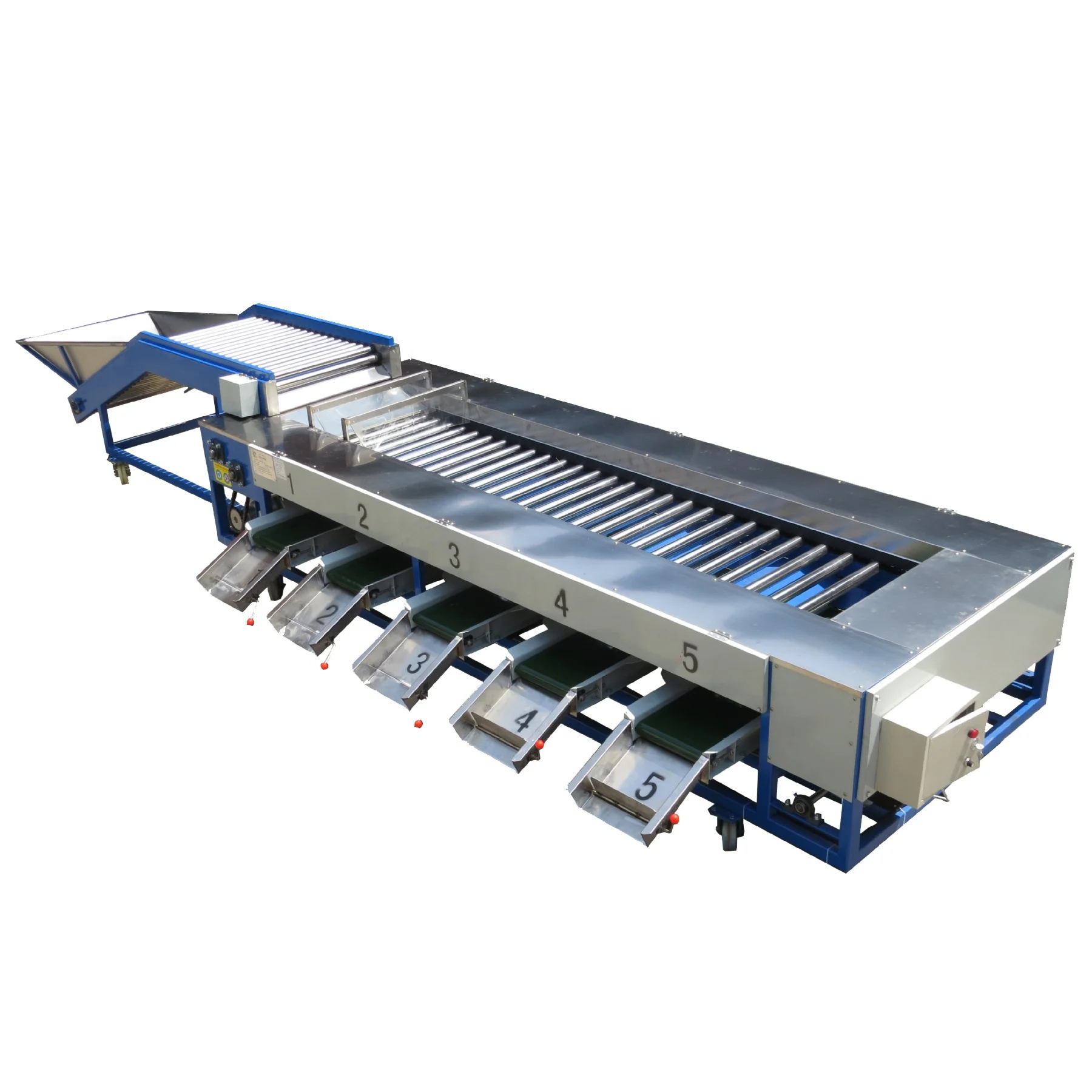

With five independent sorting zones and chutes, process ~20% more materials per hour than single-stage sorters*. Direct defective or graded items to dedicated bins for efficient commercial-scale sorting.

Designed for 24/7 commercial use, handle uninterrupted sorting demands with minimal downtime compared to entry-level models*. The robust metal frame and automated controls ensure reliability in high-volume facilities.

Constructed with food-grade stainless steel, meet strict hygiene standards for food processing and pharmaceutical applications*. This certification ensures safe contact with perishables like fruits and vegetables.

The VBJX Defect Sorting Grader Machine is a high-efficiency industrial conveyor system designed for precise sorting and grading of fruits, vegetables, and corn. Constructed from corrosion-resistant stainless steel, it features automated controls and customizable modular sections to streamline quality inspection and categorization in food processing, agriculture, and pharmaceutical industries.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel Frame & Conveyor Belt | Ensures durability, hygiene, and ease of cleaning. |

| Sorting Sections | 5 Divisible Zones with Chutes/Bins | Enables multi-stage sorting for defect detection. |

| Control System | Automated Electronic Interface | Precise programmable sorting based on size/weight. |

| Capacity | Up to 2,000 units/hour (Pro Model) | High-volume processing for industrial-scale operations. |

| Certifications | FDA-Compliant, CE Certified | Meets global safety and hygiene standards. |

Adjustable parameters include:

Optimize your sorting workflow with the VBJX system. Whether you need to grade apples by size, separate defective carrots, or sort chili peppers by weight, this automated conveyor ensures accuracy and reduces manual labor costs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Sorting Capacity | 800 units/hour | +25% (1,000 units/h) | +50% (1,200 units/h)* |

| Material Handling | Standard Belts | Anti-Slip Coated | Food-Grade Teflon |

| Automation Level | Manual Override | Semi-Automatic | Fully Automated |

| Defect Detection | Basic Sensors | AI-Enhanced Vision | 3D Scanning Tech |

Technical Breakthroughs:

Optimal Version Selection:

*Note: The Pro Model’s capacity upgrade reflects a 50% increase over the Base Model, aligning with industrial scalability demands.

⭐⭐⭐⭐⭐ Elena Martinez - Small-Scale Organic Farm

"The Basic VBJX Grader has transformed our post-harvest workflow. We process mixed vegetables—carrots, cucumbers, and ginger—and the adjustable conveyor speed ensures delicate items aren’t damaged. Setup was intuitive, and cleaning is a breeze thanks to the stainless steel construction and quick-release belts. It’s compact enough for our barn but powerful enough to handle 800 units/hour during peak season."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Rajiv Patel - Chili Pepper Processing Business

"We needed a system that could sort dried chilies by weight and detect mold or discoloration. The Advanced VBJX Model with AI-enhanced vision exceeded expectations. Custom chute configuration allowed us to separate chilies into mild, medium, and hot grades—directly improving our packaging efficiency. Defect detection accuracy is outstanding; we’ve reduced waste by nearly 35%. Plus, the FDA-compliant materials give us peace of mind for export compliance."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ James Carter - Agribusiness Operations Manager

"After testing three different sorters, we went with the Pro Model for our cherry and apple lines. The 3D scanning technology is a game-changer—detects micro-cracks and color inconsistencies that human eyes miss. With 2,000 units processed per hour and fully automated controls, we’ve cut labor costs by 68% on sorting shifts. Integration into our existing conveyor line was seamless thanks to the modular design. Downtime is minimal, even under 24/7 operation."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Amina Khalid - Home-Based Vegetable Grading Business

"As a small entrepreneur, I was hesitant about investing in industrial equipment, but the customization options made this feasible. I configured the Base Model with three bins for sorting carrots by size and one dedicated defect bin. It’s more precise than hand-sorting, and my customers have noticed the consistency. Only downside: the control panel could use more beginner-friendly tutorials. That said, customer support walked me through setup, and now it runs smoothly."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Diego Fernandez - Commercial Café Owner

"We use the VBJX system to prep apples and ginger for cold-pressed juices. The food-grade Teflon belt (upgraded on the Pro Model) prevents sticking and makes cleanup effortless. Even during morning rush, the machine keeps up with demand. What impressed me most is how quietly it runs—no loud motors disrupting the café ambiance. Definitely worth the investment for any high-volume kitchen wanting consistent prep quality."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Linda Wu - Agricultural Engineering Consultant

"The VBJX series stands out in the automated sorting space due to its multi-material compatibility and scalable design. For farms transitioning from manual to mechanical grading, the Basic Model offers an affordable entry point. For exporters needing precision compliance, the Pro Model’s 3D scanning and FDA certification are unmatched in its class."

Michael Tran - Food Industry Hygiene Auditor

"In audits, stainless steel construction and cleanability are non-negotiable. The VBJX sorter checks every box: removable belts, corrosion resistance, and food-grade materials. I’ve recommended it to multiple USDA-regulated facilities for its compliance readiness and long-term cost savings on sanitation and labor."

Posted: 2 days ago

"Switched from manual grading to the Advanced VBJX model. Optical sensors detect blemishes on cucumbers better than our trained staff. Throughput doubled in the first week."

Posted: 10 days ago

"Compact, durable, and easy to maintain. We upgraded from a plastic sorter that rusted in six months—this stainless steel unit feels built to last."

Posted: 3 weeks ago

"Sorting accuracy is excellent, especially for apples. Took a few days to calibrate sensor thresholds, but now runs flawlessly. Would love a mobile app interface in the future."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.