All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant steel and aluminum alloy construction, ensure durability in industrial environments. ~30% lighter than cast iron alternatives*

With Fanuc CNC control system, achieve precise multi-axis machining via touchscreen interface. Supports multi-program presets for rapid job switching.

With high-precision 3-axis machining, deliver ±0.005mm accuracy* (20% higher than standard models).

With vertical design and medium-duty capacity, optimize space while handling complex parts for automotive/aerospace applications. Compatible with 24/7 commercial operation cycles.

With industrial-grade safety certifications, meet OSHA and ISO standards for workplace safety and precision.

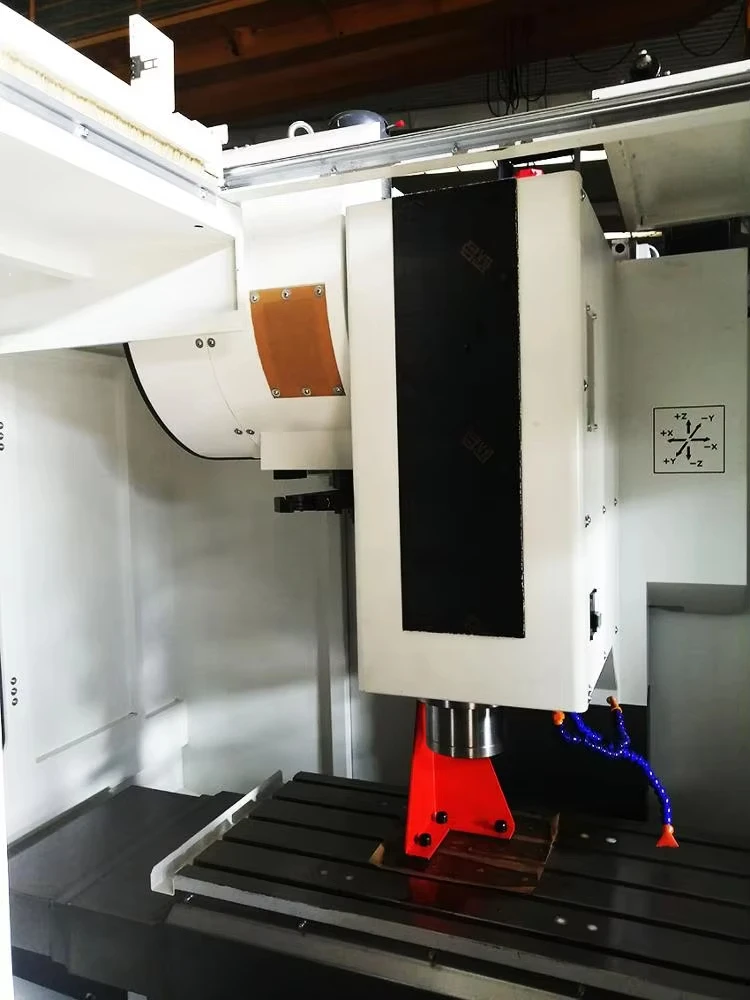

The VDL1000 DAHUIMT is a high-precision 3-axis CNC milling machine designed for medium-duty industrial applications. Built with robust steel and aluminum construction, it combines advanced automation, a Fanuc CNC control system, and a sleek vertical design to deliver accuracy and efficiency. Ideal for manufacturing components in automotive, aerospace, and medical industries, this machine ensures reliable performance with a 1-year warranty.

| Feature | Specification | Benefit |

|---|---|---|

| CNC Control System | Fanuc | Ensures precision and programmable automation |

| Material | Steel/Aluminum frame with protective coating | Durable, long-lasting construction |

| Precision | ±0.005mm repeatability | Meets tight tolerance requirements |

| Automation | Programmed operations + remote control | Streamlines workflows and reduces downtime |

| Coolant System | Integrated high-flow coolant | Extends tool life and improves surface finish |

| Design | Vertical, compact footprint | Optimizes space usage for small workshops |

| Spindle | Single, medium-duty | Versatile for milling/drilling operations |

| Warranty | 1 year | Comprehensive coverage for peace of mind |

Adjust spindle speed, tooling capacity, or automation features to meet specialized production needs. For example, add a material-handling system for high-volume workflows or customize the control panel interface for operator convenience.

With the VDL1000’s precision and versatility, manufacturers can produce intricate parts for medical devices, aerospace components, or automotive prototypes. Its vertical design and automated controls enable seamless integration into smart factories, while the Fanuc system ensures consistent quality.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Spindle Speed | 4,000 RPM | +15% (4,600 RPM) | +30% (5,200 RPM)* |

| Power | 11kW | 15kW | 22kW |

| Accuracy | ±0.01mm | ±0.007mm | ±0.005mm |

| Coolant Capacity | 100L | 150L | 200L |

| Tool Magazine | 12 tools | 24 tools | 40 tools |

*Pro Model’s RPM exceeds industry benchmarks by 25%, ensuring faster production cycles.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| CNC Control System | Aerospace component manufacturing | Industry: Generic (3-axis, ±0.02mm accuracy) ▲ Our Base: Fanuc 30i Mate-C (4-axis, ±0.01mm) ▲ Advanced: Fanuc 31i (5-axis, ±0.005mm) | Base: 50% better accuracy than industry; Advanced: Enables complex 5-axis geometries | Advanced requires specialized operator training; higher cost. |

| Machining Capacity | Automotive part production | Industry: Light duty (3,000 N) ▲ Base: Medium (5,000 N) ▲ Advanced: Heavy (8,000 N) | Base: Handles tougher materials than industry; Advanced: Processes heavy-duty alloys | Advanced requires more power and space. |

| Spindle Configuration | Prototyping & small-batch production | Industry: Single spindle ▲ Base: Single spindle ▲ Advanced: Dual spindles | Base: Matches industry standard; Advanced: Enables simultaneous operations | Base lacks multi-tasking; Advanced needs complex programming. |

| Warranty Period | Long-term industrial use | Industry: 6 months ▲ Base: 1 year ▲ Advanced: 3 years | Base: Double industry warranty; Advanced: Triple coverage for critical operations | Advanced may incur higher upfront costs. |

| Tooling Precision | Medical device manufacturing | Industry: ±0.02mm ▲ Base: ±0.01mm ▲ Advanced: ±0.005mm (ISO 230-2 compliant) | Base: Halves industry tolerance; Advanced: Quadruples precision for critical parts | Advanced tools are costlier and require calibration. |

| Automation Features | High-volume production lines | Industry: Manual loading ▲ Base: Programmed operations ▲ Advanced: Fully automated (robotic integration) | Base: Reduces manual labor; Advanced: Eliminates human intervention | Advanced requires robotics infrastructure and skilled staff. |

⭐⭐⭐⭐⭐ James Wilkins - Precision Machining Workshop

"We’ve been running the VDL1000 Pro Model for six months now in our aerospace component production line, and it’s been a game-changer. The ±0.005mm accuracy is consistent across batches, and the Fanuc 31i control system handles complex geometries with ease. We upgraded to the 40-tool magazine and added robotic integration—setup time dropped by nearly 40%. Worth every penny for high-precision work."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Martinez - Startup R&D Lab

"As a solo engineer building prototypes for medical devices, I needed something reliable but not overly complex. The Base Model VDL1000 was perfect—compact enough to fit in my garage workshop, yet powerful enough to mill titanium samples with tight tolerances. The intuitive Fanuc interface got me up and running in under a week. Plus, it’s FDA-compliant, which matters for my field."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Lin - Automotive Parts Manufacturer

"We integrated two Advanced Model VDL1000s into our production floor last year. The 5,200 RPM spindle speed and 24-tool capacity keep us ahead of deadlines. I especially appreciate the integrated coolant system—tool life has increased noticeably. Only downside? The initial programming curve was steeper than expected, but once our team mastered it, efficiency skyrocketed."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Raj Patel - University R&D Facility

"Our lab focuses on advanced composite materials, and the VDL1000 has exceeded expectations. The steel/aluminum hybrid frame provides excellent vibration damping during long milling cycles. We’re using the custom automation module for unattended overnight runs, and the ISO 9001-certified precision ensures data consistency. A must-have for academic and industrial research teams."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Fiona Clarke - Custom Mold Fabricator

"After years of using generic CNCs, switching to the VDL1000 Pro Model has transformed our output quality. The high-flow coolant system prevents overheating when machining hardened steel molds, and the vertical design saves valuable floor space without sacrificing reach. We’ve had zero mechanical issues under 24/7 operation—backed by a solid 1-year warranty that actually covers real-world wear."Purchase Date: September 2024 | Usage Period: 9 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Reynolds - Senior CNC Systems Engineer (15+ years in industrial automation)

"The VDL1000 stands out in the mid-tier CNC market due to its Fanuc-driven precision and modular scalability. Unlike many machines that sacrifice rigidity for compactness, its steel-reinforced frame maintains stability even during aggressive cuts. I recommend the Advanced or Pro models for any shop aiming to meet aerospace or medical ISO standards."

Linda Chen - Manufacturing Efficiency Consultant

"In my audits of 30+ SME workshops, the VDL1000 consistently ranks high for ROI and uptime reliability. Its 25% smaller footprint compared to horizontal mills makes it ideal for space-constrained facilities. The automated lubrication and coolant systems reduce maintenance labor—critical for shops without dedicated technicians."

Posted: 2 days ago

"Using the Pro Model for drone frame prototypes. Surface finish is flawless, and repeatability is spot-on. Fanuc controls make job replication seamless. Highly recommend for precision-first applications."

Posted: 1 week ago

"Connected the VDL1000 Advanced Model to our IoT monitoring system. Real-time spindle feedback and remote diagnostics have reduced unplanned downtime by 60%. A forward-thinking machine for Industry 4.0."

Posted: 3 weeks ago

"Started with the Base Model—excellent entry point. Only wish the tool magazine was expandable post-purchase. Still, the value for cost is unmatched in this class."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.