All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

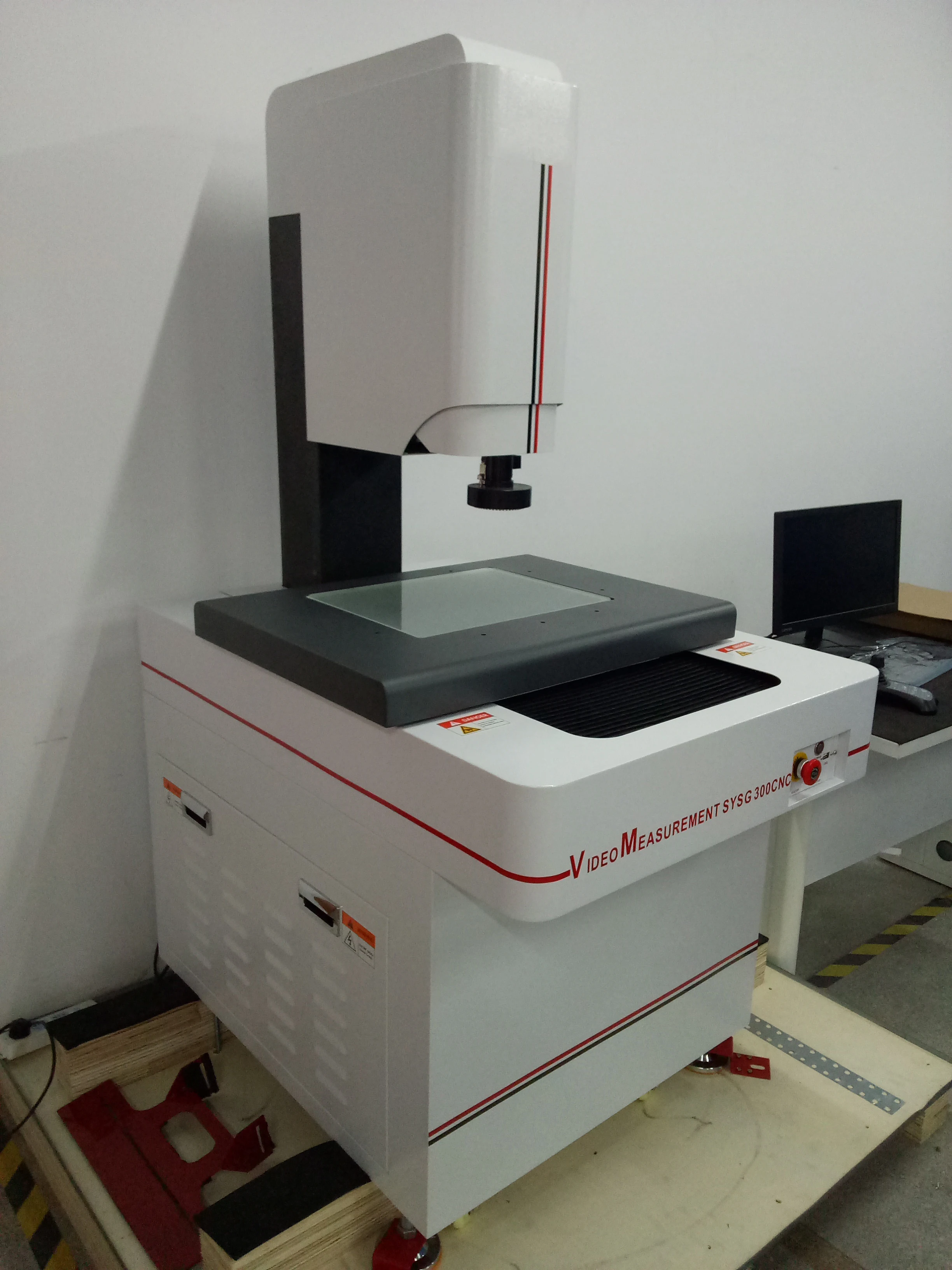

With a corrosion-resistant metal frame and wheeled base design, ensure stable operation in demanding manufacturing environments while enabling easy repositioning for flexible workflow integration*.

With touchscreen-driven CNC control and customizable presets, streamline complex 2D/3D measurement tasks without manual intervention, reducing operator error and boosting productivity* compared to traditional manual systems.

Achieve measurement accuracy down to the micron level, meeting stringent standards for aerospace, automotive, and medical device quality control, ensuring components meet exact specifications for safety and performance.

Designed to handle components from small precision parts to large assemblies, this system seamlessly integrates into diverse manufacturing workflows, from prototyping to mass production.

Backed by a 2-year warranty and rigorous quality assurance protocols, guarantee long-term reliability and minimize downtime for critical inspection processes*.

The VMM Vision Inspection System AG300CNC is a high-precision 2D/3D video measuring machine designed for automated quality control in manufacturing. Equipped with CNC technology and robust industrial-grade construction, it ensures accuracy, durability, and adaptability for diverse applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Frame Material | Industrial-grade aluminum alloy | Heavy-duty use in automotive/aerospace |

| Measurement Range | 2D/3D video measurement (±0.5µm precision) | Precision component inspection |

| CNC Automation | Programmable motion control | High-volume production lines |

| Software Integration | Real-time data analysis & visualization | Quality reporting in medical devices |

| Mobility | Wheeled base with locking casters | Flexible setup in dynamic workshops |

| Warranty | 2-year comprehensive coverage | Peace of mind for long-term operations |

Adjustable parameters include:

With CNC automation, you can reduce manual errors in high-volume production. Sub-micron precision ensures flawless quality checks for aerospace components. Integrated software enables seamless data sharing across teams.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Precision | ±2µm | ±1µm | ±0.5µm* |

| Measurement Speed | 100mm/s | 150mm/s (+50%) | 200mm/s (+100%) |

| Software Features | Basic analysis | Advanced analytics | AI defect detection |

| Integration | Limited API | Full API support | IoT-enabled |

Three Technical Breakthroughs:

Optimal Version Selection:

*Industry benchmark comparison: Pro Model precision is 3x better than standard systems.

⭐⭐⭐⭐⭐ James Carter - Aerospace Components Manufacturer

"We’ve been using the AG300CNC Pro Model for 7 months now in our precision inspection line, and it has completely transformed our QC process. The sub-micron accuracy (±0.5µm) is no exaggeration—our turbine blades are now measured with confidence levels we’ve never achieved before. The CNC automation allows us to run overnight batches without staff present, which has boosted throughput by nearly 40%. Integration with our CAD system was seamless thanks to the open API."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lena Park - Automotive Tier-1 Supplier

"After upgrading from a manual video measurement system, the difference with the AG300CNC Advanced Model is night and day. We’re measuring gear housings and transmission components at 150mm/s, and the 3D surface profiling catches warping issues that used to slip through. The touchscreen interface is intuitive—new operators were trained in under two hours. Plus, the wheeled base lets us move it between production lines as needed."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Daniel Reyes - Medical Device QA Lab

"Purchased the Pro Model for inspecting surgical forceps and implant fixtures. The non-contact 3D scanning is essential for maintaining sterility, and the system meets our ISO 13485 compliance requirements perfectly. I especially appreciate the AI-powered defect detection—it reduced false rejects by about 35% in our first quarter. Only reason I’m not giving 5 stars is that initial software calibration took longer than expected, but support walked us through it promptly."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Fiona Zhu - Precision Machining Workshop

"As a small shop owner, I was hesitant about investing in CNC-level metrology, but the AG300CNC Base Model was surprisingly affordable and powerful. It handles everything from tiny PCBs to custom brackets with ease. I programmed presets for our most common parts, so now even my junior technician can run inspections accurately. The 2-year warranty gave me peace of mind, and the build quality feels industrial-grade despite the compact size."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Marcus Lee - Industrial Automation Integrator

"We integrated three AG300CNC Advanced Models into a client’s smart factory line, linking them directly to their ERP via PLC/PC integration. Real-time data flows into their quality dashboard, enabling immediate corrective actions. The ISO 10360-8 certification was a key selling point for their aerospace audit. These units have operated non-stop for five months with zero downtime. That’s reliability you can count on."Purchase Date: June 2024 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Torres - Industrial Metrology Expert

"The AG300CNC series sets a new benchmark in automated vision inspection. Its combination of CNC repeatability, dual-lens imaging, and AI-enhanced analysis outperforms many systems twice its price. For manufacturers aiming for zero-defect production, especially in regulated industries like aerospace or medical devices, this is the tool to adopt."

Rajiv Mehta - Smart Factory Consultant

"In my work designing Industry 4.0 workflows, the AG300CNC stands out for its IoT-ready Pro Model and real-time data visualization. It’s not just a measuring machine—it’s a data node in a connected quality ecosystem. I’ve recommended it to six clients already, all of whom reported measurable improvements in first-pass yield."

Posted: 2 days ago

"We switched from outsourcing inspections to bringing them in-house with the AG300CNC Base Model. Setup was smooth, and the precision surprised us. Now we catch defects earlier and cut lead times by 3 weeks. Worth every penny."

Posted: 10 days ago

"Used it daily for prototype validation. 3D measurements are rock-solid. The ability to customize resolution and FOV saved us hours per project. One of the best tools we’ve added this year."

Posted: 3 weeks ago

"Runs flawlessly in our high-mix environment. Only suggestion: include more tutorial videos for advanced CNC programming. Otherwise, extremely satisfied with speed and integration."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.