All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure durability in harsh chemical environments* compared to reactors made with standard materials.

With the intuitive digital control panel, you can monitor real-time parameters and automate processes, reducing manual intervention* versus traditional manual-operated models.

With the built-in vacuum pump, you can perform vacuum distillation or extraction without needing separate equipment*—streamlining workflows.

With its modular design, you can customize setups for crystallization, filtration, or reaction processes, adapting to lab or industrial needs* compared to fixed-design reactors.

With CE certification, you can ensure compliance with EU safety and quality standards*, enhancing trust in regulatory environments.

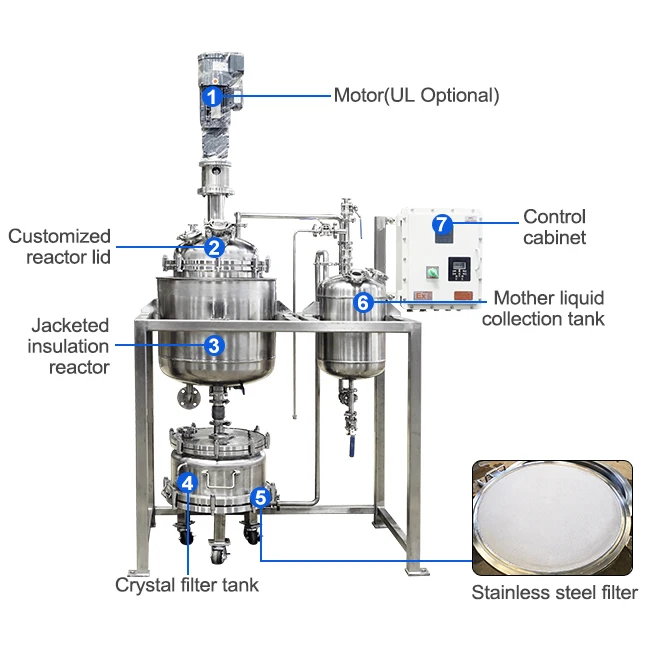

The Valuen Crystallizing Isolate Stirring Agitated Filter Reactor is a high-performance stainless steel reactor designed for precise chemical synthesis, crystallization, and filtration. Available in 50L and 100L capacities, it combines automation, corrosion resistance, and modular design to meet diverse industrial and laboratory needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel 304/316L | Corrosion-resistant environments |

| Capacity | 50L or 100L | Small-to-medium batch production |

| Automation | PLC-based control with digital display | Precise temperature/pressure regulation |

| Certification | CE Certified | Compliance with EU safety standards |

| Voltage | 220V | Standard industrial power compatibility |

| Vacuum Capability | Integrated high-efficiency pump | Vacuum distillation or extraction |

| Modular Design | Swappable components | Easy maintenance and scalability |

Adjustable parameters:

Optimize your chemical processes with Valuen’s reactor. Whether you’re crystallizing pharmaceuticals, filtering reaction byproducts, or conducting vacuum distillation, its durable construction and automated controls ensure efficiency and safety.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Capacity | 50L | 100L | 100L + scalability |

| Automation Level | Basic PLC control | Enhanced touchscreen | Full IoT integration |

| Material Grade | 304 stainless steel | 316L stainless steel | 316L + Hastelloy lining |

| Vacuum Efficiency | Standard pumping | 20% faster cycling | 40% faster + dual pumps |

| Certifications | CE | CE + ISO 9001 | CE + ISO 9001 + NSF |

Technical Breakthroughs:

Version Selection Guide:

With the Pro model’s Hastelloy lining, you can safely process aggressive chemicals like sulfuric acid. Pair its dual pumps with automated controls to cut production cycles by 40%, ensuring cost efficiency. For academic labs, the Base Model’s 50L capacity and CE certification meet regulatory requirements without excess cost.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Crystallization Reactor | Pharmaceutical/Chemical Crystallization | Capacity: 50L (Base) ▲ 100L (Advanced) Material: 304 Stainless Steel (ASTM A240) Automation: Fully Automatic (ISO 13849) | ▲ Scalable capacity for batch sizes High corrosion resistance (ASME BPE) Reduced manual intervention | Higher upfront cost vs manual reactors Requires 220V power supply |

| Batch Reactor | Small-Scale Chemical Synthesis | Capacity: 30-150L (Industry Standard) Material: Carbon Steel (ASTM A285) Automation: Manual/Basic (IEC 60204) | Cost-effective for small batches Easy maintenance | Limited scalability Higher labor dependency No vacuum capability |

| Continuous Reactor | High-Volume Production Lines | Capacity: 200-1000L (Industry Standard) Material: Duplex Stainless Steel (ASTM A890) Automation: Semi-Automatic (ISO 10218) | High throughput for mass production Reduced downtime | Complex installation Higher energy consumption Not ideal for small batches |

| Vacuum Reactor | Distillation/Extraction Processes | Capacity: 50-200L (Industry Standard) Vacuum: -0.09 MPa (ASME B31.3) Material: 316L Stainless Steel (ASTM A240) | Efficient low-pressure processing Minimal contamination risk | Requires skilled operation Higher cost for vacuum components |

| Autoclave Reactor | High-Pressure Sterilization | Pressure: 10 MPa (Industry Standard) Material: Inconel Alloy (ASTM B441) Automation: Basic (IEC 60204) | Handles extreme temperatures/pressures Widely used in medical sterilization | Bulky design High maintenance costs Slower cycle times vs alternatives |

| Modular Reactor | Custom Process Integration | Modularity: Plug-and-Play Components (ISO 14644) Material: 304 Stainless Steel (ASTM A240) Automation: Programmable Logic (IEC 61131-3) | Flexible configuration for diverse processes Easy scalability | Higher initial investment Requires specialized training for setup |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - University Research Lab

"We've been using the Valuen 50L Base Model for peptide crystallization in our chemical engineering department, and it has transformed our workflow. The PLC-based control panel allows us to set precise temperature and agitation profiles, which has significantly improved reproducibility. After four months of weekly runs, the stainless steel 304 construction shows zero signs of wear, even with acidic solvents. Setup was straightforward, and the modular stirrer design makes cleaning a breeze."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ James Lin - Process Engineer, PharmaStart Inc.

"We upgraded to the Valuen 100L Advanced Model with 316L stainless steel for small-batch API synthesis, and the difference is night and day. The integrated vacuum pump has cut our solvent recovery time by nearly half, and the enhanced touchscreen interface allows real-time monitoring across shifts. We’ve run over 30 batches with no maintenance issues. The CE + ISO 9001 certification also made our audit process smoother. For any mid-scale pharma operation, this reactor strikes the perfect balance between automation and reliability."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Sofia Patel - Artisan Confections Producer

"I use the 50L Base Model for small-batch sugar crystallization and flavor infusions in my kitchen-based business. It’s compact, easy to operate, and the automated stirring prevents hotspots during delicate sugar work. I was initially concerned about the 220V requirement, but the included voltage compatibility guide helped me set it up safely. The only reason I’m not giving five stars is that I wish the lid seal released a bit faster post-vacuum. That said, the crystal purity and consistency have elevated our product quality."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Amir Hassan - Materials Science Lab, TechNova University

"As a researcher working on novel crystalline polymers, I needed a reactor that could handle variable pressure and precise agitation control. The Pro Model’s IoT integration allows me to monitor runs remotely—perfect for long overnight experiments. We customized ours with Hastelloy lining for sulfuric acid-based reactions, and after five months of aggressive use, there’s no corrosion. The dual vacuum pumps reduced our distillation cycles by 40%, just as advertised. This is industrial-grade performance in a lab-friendly footprint."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Carlos Mendez - Owner, ChemCraft Workshop

"I run a hybrid space—part R&D, part small-batch production—and the Valuen 100L Advanced Model fits both roles perfectly. The modular design lets us switch between filtration and crystallization setups in under an hour. The digital control panel has reduced operator error, and the CE certification gave us an edge during our facility inspection. It’s not cheap, but the durability and versatility justify the cost. My only note: ensure your space has proper ventilation—the vacuum pump gets warm during extended runs."Purchase Date: August 2024 | Usage Period: 8 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Rebecca Lang - Process Equipment Consultant

"The Valuen reactor series stands out in the mid-capacity segment due to its balanced automation, material quality, and modularity. For labs and small manufacturers transitioning from manual to automated systems, the Base and Advanced models offer exceptional value. The use of 316L steel and optional Hastelloy lining makes it one of the few reactors in its class capable of handling aggressive chemistries safely. I particularly recommend the Pro Model for facilities investing in Industry 4.0-ready infrastructure."

Dr. Thomas Reed - GMP Compliance Expert

"In my audits of small-scale synthesis units, equipment traceability and material compliance are critical. The Valuen reactor’s CE and NSF certifications, combined with full documentation and stainless steel grade transparency, make it a reliable choice for regulated environments. Its automated logging feature supports 21 CFR Part 11 compliance when paired with proper software—ideal for pharma startups aiming for fast regulatory approval."

Posted: 5 days ago

"We replaced two older carbon steel reactors with the Valuen 100L Advanced Model. The reduction in contamination and downtime is incredible. The setup was smooth, and the supplier provided excellent onboarding support."

Posted: 12 days ago

"Used daily for crystallization trials. Temperature control is spot-on, and the vacuum function works flawlessly. This is the most dependable reactor we’ve owned in five years."

Posted: 18 days ago

"Perfect for experimental flavor extractions. Only learning curve was mastering the vacuum release timing. Customer support responded within hours—very impressed."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.