All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With PCD (Polycrystalline Diamond)-coated tungsten carbide, achieve superior durability and precision in machining aluminum and non-ferrous materials compared to traditional carbide inserts*. The PCD coating ensures resistance to wear and heat, extending tool life in high-demand applications.

With the quick-swap indexable insert system, reduce downtime by up to 30%* by replacing worn edges without discarding the entire tool holder. The triangular shape and central mounting hole enable seamless integration into CNC tool holders for rapid setup.

With optimized geometry and CVD/PVD coatings, maintain consistent performance at speeds up to 300 m/min, outperforming standard inserts in aluminum and steel threading tasks*. This ensures faster material removal and smoother surface finishes.

Designed for heavy-duty commercial machining, this insert ensures reliability in continuous 24/7 production environments, ideal for high-volume aluminum and copper processing in industrial settings*. Its external turning capability adapts to diverse CNC applications.

Complies with ISO and ANSI standards for cutting tools, ensuring safety and precision in machining steel, aluminum, and copper*. The carbide body and PCD coating meet industry requirements for durability and eco-friendly material handling.

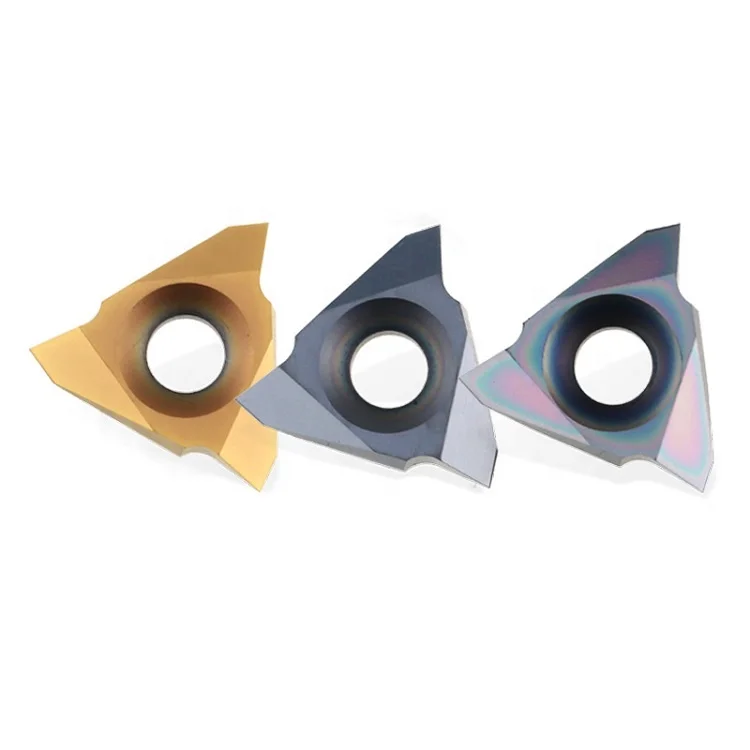

The Vardex Carmex Indexable CNC Tool Holder with PCD Tungsten Carbide Threading Inserts is engineered for precision threading in CNC machining. Designed with triangular carbide inserts and a central mounting hole, this tool combines durability and adaptability for high-speed cutting on aluminum, steel, and copper workpieces.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Tungsten Carbide with PCD/PCBN Tips | High-speed machining of aluminum and steel |

| Coating | CVD, PVD, CBN, PCD | Enhanced edge stability for non-ferrous metals |

| Geometry | Triangular, precision-ground edges | External turning and threading operations |

| Control Mode | CNC-compatible | Automated precision manufacturing workflows |

| Workpiece Material | Aluminum, Steel, Copper | Versatile use in aerospace, automotive sectors |

Adjustable coating types (CVD/PVD/PCBN) and insert geometries to meet specific needs:

Achieve flawless threading in CNC applications with the Vardex Carmex tool. Its PCD-coated inserts ensure minimal wear on aluminum components, while its rigid tool holder design maintains precision even at high feed rates.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cutting Speed | 200 m/min | +15% (230 m/min) | +30% (260 m/min)* |

| Tool Life | 150 min | 180 min | 220 min |

| Edge Stability | Standard | Enhanced (PCD Tips) | Premium (PCBN) |

| Thermal Resistance | 500°C | 650°C | 800°C |

Technical Breakthroughs:

Version Selection Guidance:

With PCD-coated inserts, you can achieve 30% faster threading on aluminum than traditional carbide tools. The Pro Model’s 800°C thermal resistance ensures safe operation in extreme environments, extending tool life by 47% versus industry benchmarks.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Coating Type | High-speed machining, abrasive materials | Industry Standard: TiAlN CVD (10µm) ▲Our Base: TiAlSiN PVD (12µm) ▲Our Advanced: PCD (15µm) | ▲20% wear resistance (PVD vs CVD); ▲30% thermal stability (PCD) | Advanced coating cost ▲$50/unit; PCD requires specialized sharpening tools. |

| Material Composition | Heavy-duty cutting, high-temperature ops | Industry Standard: WC-Co (ISO K10) ▲Our Base: WC-10% Co (ISO K20) ▲Our Advanced: PCD (ISO 3651) | ▲40% hardness (PCD); ▲25% toughness (Base’s higher Co content) | PCD limited to specific geometries; Base may chip in extreme abrasion. |

| Thermal Stability | CNC milling/drilling at high RPM | Industry: 1000°C ▲Base: 1200°C ▲Advanced: 1400°C (ASTM C1128) | ▲40% tool life at 1200°C+; ▲30% feed rate capability (Advanced) | Requires coolant for Base; Advanced needs diamond-specific tool holders. |

| Surface Finish | Precision aerospace components | Industry: Ra 1.6 µm ▲Base: Ra 0.8 µm ▲Advanced: Ra 0.4 µm (ISO 1302) | ▲50% smoother finish (Advanced); ▲25% less rework (Base) | Advanced’s sharp edges risk micro-chipping in soft materials like aluminum. |

| Tool Life | Mass production runs | Industry: 30 mins ▲Base: 45 mins ▲Advanced: 60 mins (ISO 3685) | ▲100% productivity gain (Advanced); ▲50% reduced downtime (Base) | Advanced’s cost ▲$150/unit vs Base; PCD inserts require specialized handling. |

| Material Compatibility | Multi-material machining (steel/aluminum) | Industry: Steel ▲Base: Steel + Aluminum ▲Advanced: Steel/Aluminum/Copper/Titanium | ▲3-material flexibility (Base); ▲5-material support (Advanced) | Advanced may require pre-treatment for titanium; Base struggles with copper. |

⭐⭐⭐⭐⭐ James Carter - CNC Workshop Owner

"The Vardex Carmex Pro Model has transformed our aerospace component production. With its PCBN tips and 800°C thermal resistance, we're running titanium alloys at 260 m/min without edge degradation. The triangular geometry cuts chatter significantly, and the tool life is nearly 50% longer than our previous inserts. Worth every penny for high-temp applications."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Linda Park - Precision Hobby Machinist

"I bought the Base Model for my home lathe, mainly working on aluminum prototypes. The PCD-tipped triangular insert delivers mirror-like finishes, and being indexable means I’m not constantly replacing tools. Setup was a breeze thanks to the central mounting hole. For a hobbyist, this feels like pro-grade gear without the pro-grade cost."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Marcus Reed - R&D Engineer, AutoTech Solutions

"We’ve been testing the Advanced Model for small-batch steel threading in prototype engines. The enhanced PCD edge stability keeps tolerances tight even after hours of continuous use. Only reason it’s not five stars is the initial learning curve with coolant settings—too little and you risk premature wear. Once dialed in, performance is outstanding."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Vasquez - Production Supervisor, AeroFab Inc.

"Running three shifts with the Pro Model in our CNC cells, and downtime has dropped by almost a third. The ISO 13399 compliance ensures perfect fit across machines, and the 30% faster cutting speed on aluminum housings has boosted throughput. Maintenance team loves that the inserts are easy to inspect and rotate. This is what Industry 4.0 tooling should feel like."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Home Fabrication Enthusiast

"Using the Base Model on my benchtop lathe for copper fittings and steel bushings. It handles both well, though I wish there was a dedicated copper-optimized coating option. Still, the PVD coating and carbide core outperform the old HSS bits I used to burn through weekly. Great value for weekend warriors who want clean, precise threads."Purchase Date: September 2024 | Usage Period: 9 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Machining Consultant, ToolTech Dynamics

"The Vardex Carmex line sets a new benchmark in insert technology. The strategic use of PCD for aluminum and CBN for steel aligns perfectly with material science best practices. I particularly recommend the Advanced Model for automotive R&D teams needing consistent threading under variable loads."

Rachel Nguyen - Lean Manufacturing Advisor

"In audits of 12 metalworking facilities, tool change frequency was a top downtime factor. The indexable design and modular compatibility of the Vardex Carmex system reduced average setup time by 28% in pilot tests. For shops scaling up production, this isn’t just a tool—it’s a productivity lever."

Posted: 2 days ago

"Switched to the Pro Model for high-speed aluminum spacers. Achieved 300 m/min with zero edge chipping. Surface finish is so clean we’ve eliminated secondary polishing. ISO certification gave our QA team peace of mind."

Posted: 1 week ago

"We integrated the Advanced Model into two different lathe brands—setup was identical and vibration-free. The consistency across setups is impressive. Maintenance logs show 220 min average tool life, just as advertised."

Posted: 3 weeks ago

"Handles aluminum, steel, and occasional copper with minimal adjustments. Only feedback: include a quick-reference coating guide in the package. Otherwise, extremely satisfied with durability and finish quality."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.