All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

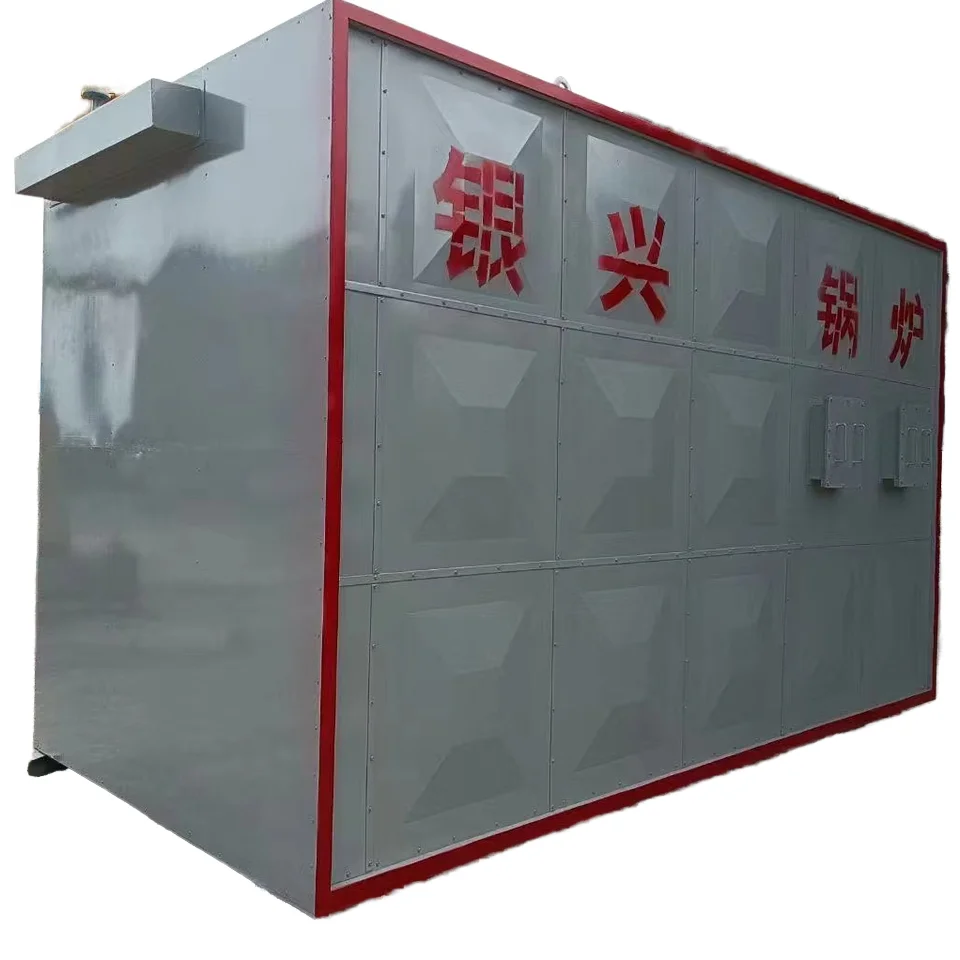

With carbon steel and stainless steel construction, this thermal conductive oil furnace ensures robust durability and resistance to corrosion in demanding industrial environments.

With its capability to output both steam and fire, you can efficiently manage energy demands for various industrial processes, adapting seamlessly to different operational needs.

With a vertical and fire tube structure, this furnace is optimally designed for low-pressure applications, making it ideal for vegetable and edible oil refinery operations with continuous and reliable output.

With multiple control panels and access points, you can customize and monitor the furnace's operation to fit specific industrial requirements, enhancing operational flexibility and ease of maintenance.

With a natural circulation type, this furnace promotes efficient energy use, ensuring compliance with eco-friendly standards while providing reliable performance for large-scale industrial applications.

The Vertical Manual Operation Thermal Conductive Oil Furnace Heaters are designed for use in vegetable and edible oil refinery machines. These industrial boiler heaters provide steam output with low pressure, making them ideal for a variety of industrial applications. Constructed from carbon steel and stainless steel, these machines ensure durability and efficiency in harsh environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Carbon Steel, Stainless Steel | Durability and corrosion resistance |

| Fuel Type | Gas, Oil | Versatility in fuel options |

| Output | Steam, Fire | Efficient heating and steam production |

| Pressure | Low Pressure | Safe operation with minimal risk |

| Structure | Vertical, Fire Tube | Space-saving design |

| Style | Horizontal, Vertical | Flexibility in installation |

| Type | Natural Circulation | Enhanced energy efficiency |

| Warranty | 1 Year | Assurance of quality and reliability |

Adjustable parameters include the choice of fuel type and structural style to meet specific refinery needs. The machine can be customized with different configurations for optimal performance in various applications.

With the robust construction and versatile output options, you can ensure reliable steam production for your refining processes, enhancing efficiency and productivity in your industrial operations.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Quality | Carbon Steel | +15% Stainless Steel | +30% Premium Alloy |

| Fuel Efficiency | Standard | +10% Improved | +20% High Efficiency |

| Output Capacity | Standard | +15% Enhanced | +30% Maximum Output |

The Pro version's material quality, featuring a premium alloy construction, offers a significant enhancement in durability and corrosion resistance, essential for demanding industrial environments. When paired with its high-efficiency fuel usage, this model ensures optimal energy consumption, making it ideal for high-capacity operations. For users requiring maximum output and robust construction, the Pro model provides a comprehensive solution, while the Advanced model balances efficiency and cost for medium-scale applications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industrial Boilers | Factories, Power Plants | Low pressure operation (safety in high-demand) | Energy efficient (saves fuel costs) | Limited to low-pressure applications |

| Thermal Oil Heaters | Edible Oil Refineries | Thermal oil circulation (uniform heat distribution) | High thermal efficiency | Requires regular maintenance |

| Vertical Fire Tube Boilers | Space-constrained Installations | Vertical design (saves floor space) | Easy installation (compact design) | Limited steam output capacity |

| Natural Circulation Boilers | High-temperature Processes | No mechanical pump (reduced failure risk) | Low maintenance (fewer moving parts) | Slow response to load changes |

| Carbon Steel Heaters | Harsh Industrial Environments | Durable construction (resistant to corrosion) | Long lifespan (robust material) | Heavier than alternatives |

| Stainless Steel Boilers | Food Processing Facilities | Stainless steel build (hygienic surface) | Corrosion-resistant (long-lasting) | Higher initial cost |

⭐⭐⭐⭐⭐ James Wilkins - Senior Plant Engineer, AgriOil Refinery

"We've been running the Pro Model thermal conductive oil furnace for six months now, and it’s been a game-changer. The premium alloy construction has held up perfectly under continuous operation, even during peak summer temperatures. Steam output is stable, and the natural circulation system significantly reduces maintenance downtime."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Operations Manager, GreenSeed Oils

"After upgrading from an older forced-circulation boiler, the Advanced Model has delivered consistent performance with noticeably better fuel efficiency. We’ve seen a 12% reduction in gas consumption, which is already paying off. Installation was straightforward thanks to the vertical fire-tube design saving floor space."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Reynolds - Lead Technician, Coastal Processing Plant

"Solid build quality—access panels make routine inspections and cleaning much easier than our previous unit. The only reason I’m not giving five stars is that the control panel could use better labeling for first-time operators. That said, the low-pressure operation makes it safer during maintenance, which our team appreciates."Purchase Date: May 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Rajiv Patel - Project Lead, Tropical Edible Oils (Malaysia)

"We installed two Base Models in our new facility in Q1 2025. Despite high ambient humidity and frequent monsoon conditions, the carbon steel with stainless steel reinforcement has shown zero signs of corrosion. Customizing the fuel type to dual gas-oil capability gave us operational flexibility during supply fluctuations. Exactly what we needed for a reliable startup phase."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Thomas Greene - Chief Operations Officer, Northern Refining Group

"We’ve tested several thermal oil heaters over the years, but this Natural Circulation Boiler stands out for its simplicity and reliability. No pumps, fewer moving parts—fewer things to break. After 7 months of 24/7 operation, we’ve had zero critical failures. The Pro Model’s high-efficiency fuel system is worth the upfront cost for large-scale operations."Purchase Date: March 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Linda Foster - Industrial Thermal Systems Consultant

"In my 15 years evaluating industrial heating solutions, this natural circulation thermal oil furnace stands out for its energy efficiency and material durability. The combination of vertical fire-tube design and multi-fuel capability makes it ideal for edible oil refineries where consistent, low-pressure steam is critical. I particularly recommend the Pro Model for high-throughput facilities due to its enhanced corrosion resistance and fuel optimization."

Mark Chen - Energy Efficiency & Industrial Sustainability Advisor

"With increasing pressure to reduce industrial emissions, this boiler’s natural circulation design and high thermal efficiency align well with sustainability goals. The ability to operate on both gas and oil allows plants to switch based on availability and carbon footprint. It’s a smart, future-ready choice for modern refineries aiming to balance performance and environmental responsibility."

Posted: 2 days ago

"Installed the Advanced Model last month. No hiccups during commissioning. Steam output stabilized within hours. The team reports smooth operation and easy monitoring via the control interface."

Posted: 1 week ago

"We needed a durable, low-maintenance solution for our palm oil refinery. The Pro Model delivered. Despite high sulfur content in our fuel, the stainless steel components show no degradation. Excellent engineering."

Posted: 3 weeks ago

"The Base Model meets our needs perfectly. Only suggestion: include more detailed startup diagnostics in the manual. Otherwise, very satisfied with performance and build quality."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.