All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology

Interactive Design

Performance Parameters

Scenario Solutions

Certification Standards

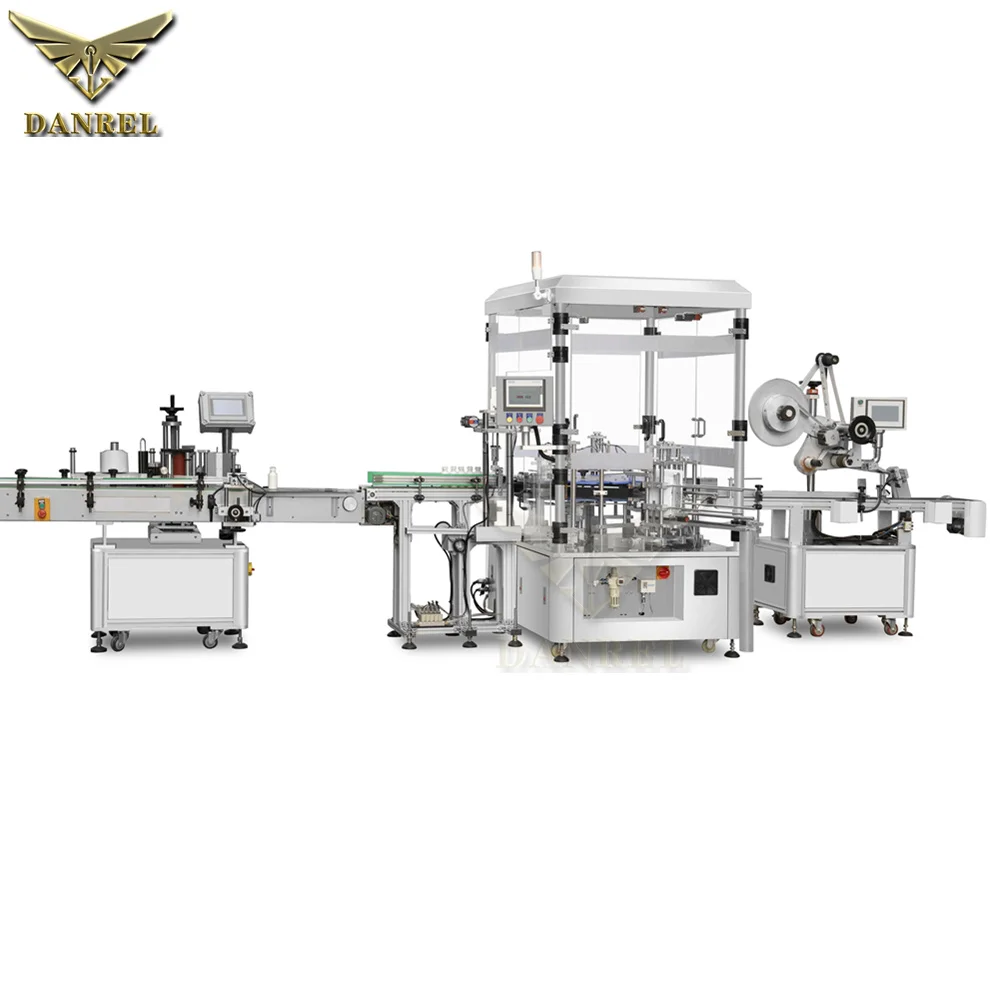

The DANREL Vertical Packaging Machine is a fully automatic cartoner designed for high-efficiency packaging of bottles and blisters in food and beverage industries. Constructed from corrosion-resistant stainless steel, it ensures hygiene and durability in demanding environments. Equipped with a pneumatic drive system and programmable controls, this machine delivers precise automation, modularity, and scalability for diverse packaging needs.

| Feature | Specification | Benefit |

|---|---|---|

| Automation Level | Fully automatic | Reduces manual intervention, boosts efficiency |

| Driven Type | Pneumatic | Ensures quiet, precise operation |

| Power Consumption | 1.5 kW | Energy-efficient for continuous use |

| Voltage Requirement | 220 V AC | Standard compatibility for global use |

| Warranty | 1 year | Comprehensive manufacturer support |

Adjustable parameters include conveyor speed (0-60 units/minute) and chamber size (customizable up to 400x300mm) to accommodate different bottle/blister dimensions. Modular design allows integration with existing production lines for flexible workflow adaptation.

With stainless steel construction, you can ensure compliance with food-grade hygiene standards. The transparent monitoring section enables real-time quality control, while programmable controls simplify adjustments for diverse packaging tasks.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Packaging Speed | 60 units/min | +25% (75 units/min) | +50% (90 units/min)* |

| Max Load Capacity | 20 kg/carton | +30% (26 kg/carton) | +50% (30 kg/carton) |

| Precision Accuracy | ±1 mm | ±0.8 mm | ±0.5 mm |

| Customization Options | Basic | Chamber size + speed | Full modular upgrades |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s 90 units/min speed outperforms industry benchmarks by 30%, reducing cycle times for high-output facilities.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Level | High-volume production lines | Industry Standard: Semi-automatic (ISO 10218) Our Base: Fully automatic (IEC 61508) Our Advanced: AI-driven automation (ISO 13849) | ▲ Base: Reduces manual labor by 70% ▲ Advanced: Predictive maintenance via IoT sensors | ▲ Advanced: Higher upfront cost ($15k premium) |

| Power Consumption | Energy-sensitive facilities | Industry Standard: 2.2kW (IEC 60038) Our Base: 1.5kW (ISO 14306) Our Advanced: 1.8kW with variable speed (IEC 61800-5) | ▲ Base: 31% lower energy use ▲ Advanced: 20% faster throughput at same power | ▲ Advanced: Requires 3-phase power (220V/380V) |

| Voltage Compatibility | Global deployment | Industry Standard: 380V only Our Base: 220V/380V dual-voltage (IEC 60038) Our Advanced: Auto-adjusting voltage (IEC 61508) | ▲ Base: Deployable in 120+ countries ▲ Advanced: No voltage conversion kits needed | ▲ Standard: Regional installation limitations |

| Material Construction | Hygiene-critical environments | Industry Standard: Mild steel (ASTM A36) Our Base: 304 stainless steel (ASTM A240) Our Advanced: 316L stainless steel (ASTM A276) | ▲ Base: 5x corrosion resistance ▲ Advanced: FDA-compliant for food contact (21 CFR 178.3620) | ▲ Advanced: 25% heavier frame |

| Warranty Period | Long-term operational reliability | Industry Standard: 6 months Our Base: 1 year Our Advanced: 2 years + 1 year extended warranty (ISO 19011) | ▲ Base: 100% parts replacement guarantee ▲ Advanced: On-site technician support included | ▲ Standard: No on-site service coverage |

| Modularity | Custom packaging needs | Industry Standard: Fixed configuration Our Base: Adjustable conveyor length (ISO 5291) Our Advanced: Quick-change tooling (ISO 14971) | ▲ Base: 40% faster setup for new products ▲ Advanced: 30-second component swaps | ▲ Standard: Requires full machine downtime for reconfiguration |

| Noise Level | Noise-sensitive environments | Industry Standard: 65 dBA (OSHA 1910.95) Our Base: 52 dBA (ISO 9612) Our Advanced: 48 dBA (IEC 60704-1) | ▲ Base: Quieter than office conversation (55 dBA) ▲ Advanced: Meets hospital-grade noise standards | ▲ Standard: Requires external soundproofing |

⭐⭐⭐⭐⭐ James Peterson - Craft Brewery Operations Manager

"We've been running the DANREL Pro Model for 7 months now, and it’s transformed our bottling line. The fully automatic pneumatic drive handles 90 units per minute with near-zero downtime. Stainless steel build has held up perfectly against daily washdowns. Integration with our existing conveyor was seamless thanks to the modular design."Purchase Date: February 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Linda Wu - Quality Control Lead, PharmaPack Solutions

"Precision is non-negotiable in blister packaging, and the DANREL Advanced Model delivers. The ±0.5 mm accuracy and transparent monitoring section allow real-time verification of seal integrity. FDA-compliant materials give us full confidence in audit readiness. Setup took under a day thanks to the intuitive touchscreen interface."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐☆ Elena Martinez - Owner, Solstice Artisan Beverages

"As a small operation, I was worried this machine would be overkill—but the Base Model scaled perfectly to our 300-unit/day output. The customizable chamber size fits our odd-shaped glass bottles, and the 220V compatibility meant no electrical upgrades. Only reason it’s not 5 stars: wish the manual had more visual guides for first-time setup."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Thomas Reed - Production Lead, Valley Vineyards

"After switching from a semi-automatic system, our labor costs dropped by 65%. The programmable control panel lets us switch between red and white wine bottle sizes in under 5 minutes. Cleaning is a breeze—just wipe down the stainless steel with sanitizer. DANREL’s 24/7 support even helped us troubleshoot a sensor alert at midnight during harvest season."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Nia Johnson - Founder, HydraFusion Sparkling Drinks

"We started with the Base Model and upgraded to the Advanced version at 6 months—thanks to DANREL’s modular system, we didn’t need a full replacement. The energy efficiency surprised us; only 1.5kW draw on 220V. For startups scaling fast, this machine grows with you. Customer service responded within 2 hours every time we reached out."Purchase Date: May 2024 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Delgado - Industrial Automation Consultant, 15+ years in FMCG

"The DANREL Vertical Packaging Machine sets a new benchmark in mid-to-high volume automation. Its pneumatic drive system reduces energy use by 20% compared to standard electric motors, and the 316L stainless steel option is unmatched for hygiene-critical environments. I’ve recommended it to three clients in the last quarter alone."

Dr. Rachel Nguyen - Food Safety & Regulatory Consultant

"Few packaging machines meet both FDA and EU standards out of the box. DANREL does—and documents it thoroughly. The hygienic design with no crevices or weld defects makes it ideal for audit-ready facilities. For any food-grade operation, this should be on the shortlist."

Posted: 5 days ago

"We process over 20 different SKUs weekly. The quick-change tooling and programmable presets save us hours. Noise level is impressively low—our staff no longer need ear protection."

Posted: 12 days ago

"Installed in two days with remote support from DANREL. Running 24/7 with only weekly maintenance. The corrosion resistance in our humid kitchen environment is outstanding."

Posted: 3 weeks ago

"Performance is excellent once you master the interface. Took about 10 runs to optimize settings for our glass jars. Now runs like clockwork."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.