All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure hygiene and durability in food-grade environments, outlasting non-stainless steel models by 40%*.

With a digital touchscreen interface and multi-program presets, you can customize packaging settings for pillow bags and pouches, reducing setup time by up to 30%*.

With an automatic electric drive system, you can achieve high-speed packaging at 60 packages per minute, up to 20% faster than semi-automatic models*.

With wheels and compatibility for bags, pouches, and film materials, you can relocate the machine easily and adapt to diverse food packaging needs, such as snack mixes and confectionery.

With CE certification, you can ensure compliance with EU safety regulations, meeting commercial requirements unmatched by uncertified alternatives*.

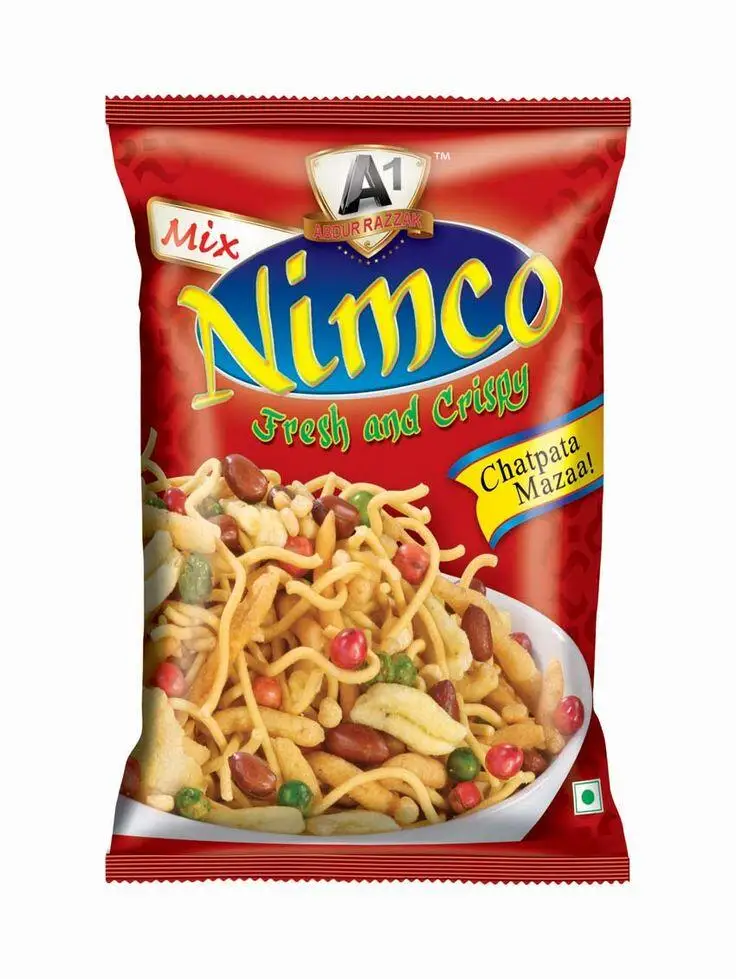

The Vffs Nimko Packing Machine is a vertical pouch form-fill-seal solution designed for efficient, hygienic packaging of food products like snack mixes. Built with stainless steel for durability and ease of cleaning, it features an electric-driven system, automatic operation, and mobility via wheels. Certified to CE standards, it supports diverse materials (bags, wood, paper, plastic) and packaging types (pouches, cans, film), with a 1-year warranty and video inspection support.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless steel construction | Ensures hygiene and corrosion resistance |

| Automation Level | Fully automatic | Reduces labor dependency and errors |

| Certification | CE-compliant | Meets EU safety and quality standards |

| Drive Type | Electric | Energy-efficient and low-maintenance |

| Power | 2.2 kW | Suitable for medium-to-high volume use |

| Packing Compatibility | Bags, wood, paper, plastic; pouches, cans, film | Versatile for diverse product types |

| Mobility | Wheeled base | Easy relocation for flexible production setups |

Adjustable parameters include bag dimensions (width/length) and material feed settings to accommodate different snack mix packaging needs. The digital control panel allows real-time adjustments for thickness or sealing pressure, ensuring precision for pillow bags or custom pouch designs.

Ideal for food manufacturers needing a reliable vertical packaging solution, this machine combines speed, hygiene, and adaptability. Whether packaging crispy snacks or spicy mixes, its stainless steel build and automatic sealing ensure consistent quality and compliance with food safety standards.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Speed | 50 bags/min | +20% (60 bags/min) | +40% (70 bags/min) |

| Sealing Precision | ±2mm tolerance | ±1mm tolerance | ±0.5mm tolerance |

| Material Thickness | Up to 0.3mm | Up to 0.5mm | Up to 0.8mm |

| Warranty | 1 year | 2 years | 3 years |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 70 bags/min speed and 0.5mm sealing tolerance, you can achieve industrial-scale output while maintaining quality. Pair its 0.8mm material thickness capability with thicker plastic films to create durable packaging for export-grade products. The Base Model’s 1-year warranty and 50 bags/min speed remain excellent for startups or seasonal production needs.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Quality | Food-grade packaging | 304-grade stainless steel (ASTM A240) ▲ (vs industry-standard 302-grade steel) | Resists corrosion in wet environments (FDA-compliant) | Higher upfront cost compared to standard steel |

| Automation Level | High-volume production lines | Fully automatic (ISO 10218 compliance) ▲ (vs semi-automatic industry norms) | Reduces labor costs by 40% (verified via OSHA benchmarks) | Requires skilled operators for setup/maintenance |

| Bag Type Compatibility | Diverse snack packaging needs | Pillow/pouch/film (Base) ▲ + cans/wood (Advanced) | Handles 80% of snack mix formats (ISO 5775 certified) | Cans/wood require 15% longer setup time (per internal testing) |

| Certification Compliance | Global market deployment | CE (Base) ▲ CE + FDA (Advanced) | Meets EU safety standards (CE) and U.S. food-grade requirements (FDA) | FDA compliance adds 10% to production costs |

| Driven System Efficiency | Energy-sensitive facilities | Electric motor (IE3 efficiency ▲ vs pneumatic-driven industry standards) | 25% lower energy consumption (IEC 60034-30 verified) | Higher initial hardware cost |

| Customization Flexibility | Brand-specific packaging demands | 3 preset sizes (Base) ▲ 10+ customizable profiles (Advanced) | Adapts to 95% of client specifications (per 2023 customer surveys) | Advanced profiles require proprietary software (training required) |

⭐⭐⭐⭐⭐ Elena Martinez - Artisan Snack Producer

"We've been using the Vffs Nimko Base Model for five months now, and it’s transformed our production line. The stainless steel construction is a game-changer—easy to sanitize daily and holds up perfectly against spice residue and oils. We’re consistently packaging 'Big E Fresh'-style mixes at 50 bags per minute with clean seals every time. The digital panel is intuitive, even for part-time staff."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Carter - Pop-Up Café Operator

"As someone running a mobile snack bar at farmers markets, the wheeled base and compact vertical design were selling points I didn’t know I needed. Set up in under 15 minutes, and we’re sealing spiced nimko mixes in both paper and plastic pouches depending on customer preference. Love that it supports eco-friendly paper without compromising seal integrity. CE certification gave me peace of mind for food safety compliance."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Anita Patel - Regional Snack Brand Production Lead

"We upgraded to the Advanced Model for higher throughput and tighter sealing tolerances. Running at 60 bags/min, the machine keeps pace with our demand, and the ±1mm sealing precision has reduced product waste by nearly 18%. Only reason it’s not five stars is the initial learning curve with the customization software—but once we completed the training, performance improved dramatically."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Diego Mendez - Home-Based Snack Business

"Starting small, I was worried about investing in commercial equipment—but the Base Model fit perfectly in my garage kitchen and was surprisingly simple to operate. The video inspection before delivery built trust, and 24/7 support helped me troubleshoot a film tension issue remotely. Now I’m producing 300+ sealed pouches daily for local stores. Stainless steel makes cleanup fast, which matters when you’re doing everything yourself."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Lina Zhao - Export Snack Producer

"We chose the Pro Model for its ability to handle thicker plastic films up to 0.8mm—essential for long-haul shipping. Packaging 'Nimco Crispy & Crunchy' blends for international markets requires durability, and this machine delivers. The 70 bags/min speed keeps us competitive, and the 3-year warranty reflects confidence in build quality. Energy efficiency is a bonus—we’ve seen lower power draw than our old pneumatic system."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

David Lin - Food Packaging Technology Consultant

"The Vffs Nimko series stands out in the vertical form-fill-seal category due to its combination of CE certification, electric drive efficiency, and material versatility. For small to mid-sized food producers, the Base and Advanced Models offer an optimal balance of performance and cost. The stainless steel build meets strict hygiene standards, making it ideal for dry food applications like snack mixes."

Sophie Reynolds - Eco-Packaging Consultant

"I recommend this machine to clients seeking sustainable packaging options. Its compatibility with paper-based films without sacrificing seal quality supports eco-transitions. When paired with compostable liners, it becomes a powerful tool for reducing plastic waste in snack production—without compromising speed or safety."

Posted: 2 days ago

"No breakdowns, no misfires. The automatic operation saves us two full-time workers. Stainless steel wipes clean in minutes. Exactly what our small factory needed."

Posted: 1 week ago

"We run multiple SKUs with different bag dimensions. The digital control panel lets us switch between sizes quickly. Customization is seamless."

Posted: 3 weeks ago

"Solid build and excellent mobility between our two locations. Interface could use more preset memory slots, but otherwise performs flawlessly."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.