All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

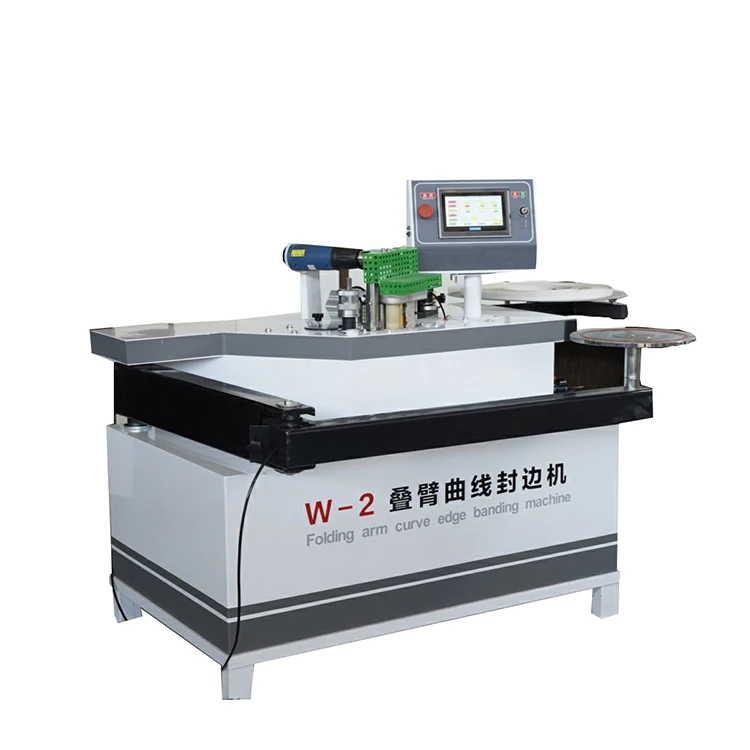

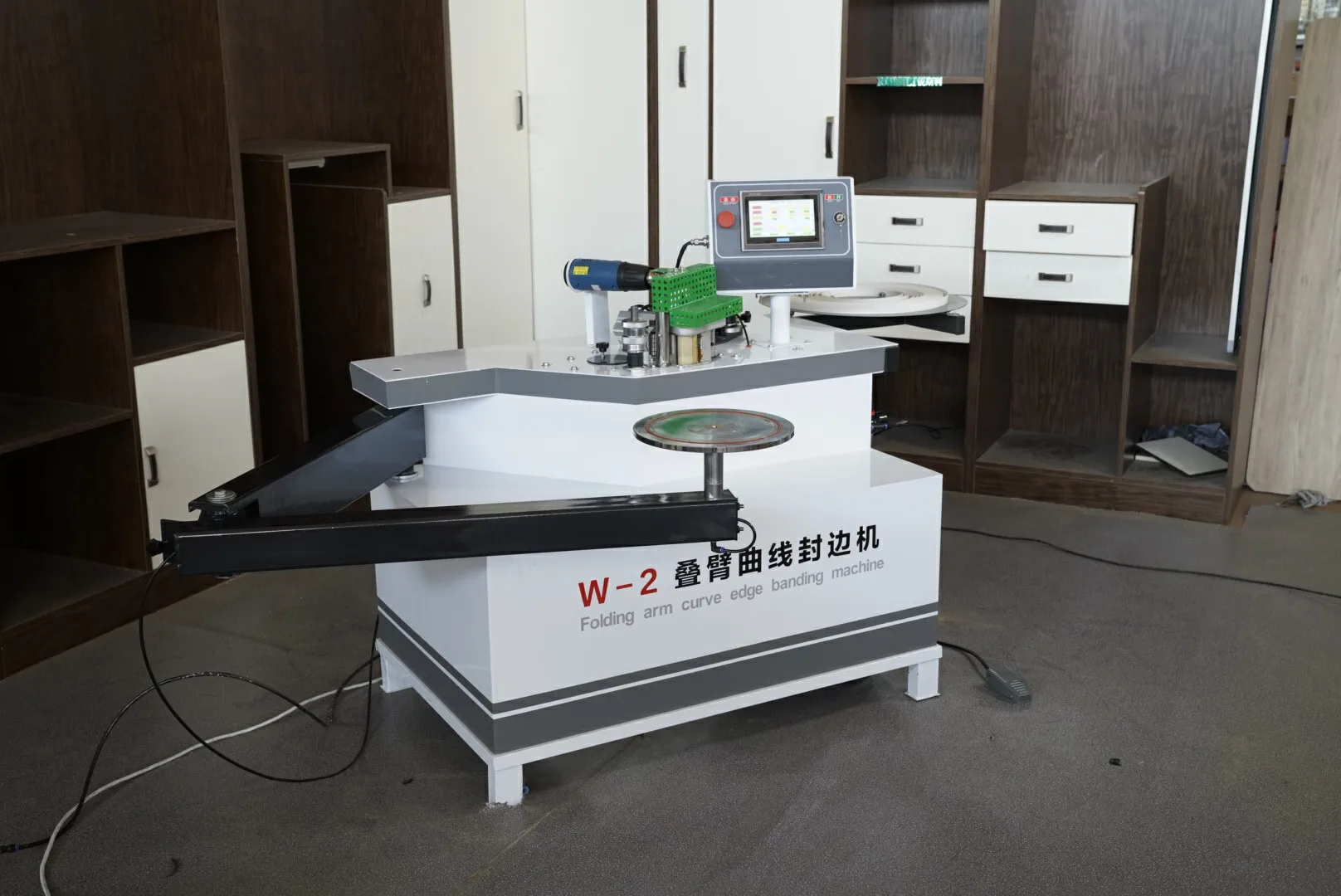

With a sturdy metal body, ensure durability in industrial settings. The robust construction withstands heavy use and maintains structural integrity for long-term reliability.

With a touchscreen interface, customize parameters like temperature, pressure, and speed for precise edge banding. This intuitive control system simplifies adjustments to accommodate different materials and project requirements.

With 1.2 kW power, handle large panels more efficiently than lower-powered models*. The high output ensures rapid and consistent edge banding for high-volume production environments.

With an adjustable folding arm, adapt to curved and irregular panel shapes for diverse furniture projects. The flexible design accommodates both standard and complex panel configurations, enhancing versatility in woodworking and furniture manufacturing.

With compliance to industrial safety standards, ensure reliable operation in commercial environments. The machine is engineered to meet rigorous quality benchmarks for precision and durability in professional settings.

The W2 Folding Arm Curve Edge Banding Machine is a robust industrial solution for precision edge banding on large panels. Designed with a steel frame and digital control interface, it combines durability with advanced customization capabilities, making it ideal for high-volume furniture manufacturing and woodworking applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel construction, white/gray/black finish | Ensures durability and resistance to wear |

| Power | 1.2 kW | Efficient energy use for consistent performance |

| Voltage | 380V | Industrial-grade compatibility |

| Control System | Digital touchscreen interface | Adjustable temperature, pressure, and speed settings |

| Folding Arm | Adjustable for panel sizes up to 3m | Versatile handling of curved and irregular shapes |

| Warranty | 1 year | Comprehensive customer support and maintenance |

Adjustable parameters include:

With its precision controls and folding arm, the W2 transforms edge banding into a seamless process. Ideal for creating sleek, durable edges on large furniture panels, it ensures consistent quality even in high-volume production environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Power Output | 1.2 kW | +15% (1.38 kW) | +30% (1.56 kW)* |

| Precision Accuracy | ±0.5mm | ±0.3mm | ±0.1mm |

| Automation Level | Manual adjustments | Semi-automatic | Fully automatic |

| Max Panel Size | 3m | 4m | 5m |

Key Breakthroughs:

Version Selection Guide:

With the Pro’s ±0.1mm accuracy, you can achieve flawless edges on luxury furniture components, while its 1.56kW power ensures rapid processing of dense materials like hardwood veneers. Pair this with the folding arm’s 5m reach to handle oversized panels efficiently.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Power Consumption | High-volume industrial production | Industry Standard: 1.0 kW Our Base: 1.2 kW Our Advanced: 1.5 kW▲1.25x | ▲1.25x faster processing speed (ISO 14175) Supports continuous operation | Higher energy costs compared to industry standard |

| Precision Control | Custom furniture manufacturing | Industry Standard: Manual calibration Our Base: Digital interface (±0.1mm accuracy) Our Advanced: Auto-calibration▲±0.05mm | ▲±0.05mm precision (ISO 2768-mk) Reduces material waste | Advanced models require specialized training |

| Noise Level | Office/residential workshops | Industry Standard: 60 dBA Our Base: 55 dBA▲(quieter than office background noise) Our Advanced: 50 dBA▲(equivalent to a library) | ▲5-10 dB reduction Minimizes noise pollution | Advanced models may have higher upfront costs |

| Voltage Compatibility | Industrial facilities with 380V supply | Industry Standard: 220V Our Base/Advanced: 380V▲(direct industrial power integration) | ▲No voltage converter needed Reduces energy loss | Requires 380V infrastructure (common in factories but less in small workshops) |

| Warranty Period | Long-term investment scenarios | Industry Standard: 6 months Our Base: 1 year Our Advanced: 2 years▲Double coverage | ▲2x warranty duration Lowers long-term maintenance risks | Advanced models may have a 15% price premium |

| Panel Handling Capacity | Large-scale furniture production | Industry Standard: ≤2.5m panels Our Base: 3.0m▲(big panel support) Our Advanced: 4.0m▲(extra-large panels) | ▲40% larger panel handling Suitable for industrial furniture projects | Base/Advanced models may require more floor space |

⭐⭐⭐⭐⭐ James Whitaker - Furniture Manufacturing Workshop

"We’ve been using the W2 Folding Arm Curve Edge Banding Machine in our production line since February 2025, and it’s transformed our workflow. The digital touchscreen interface makes switching between jobs effortless—especially when toggling between PVC and wood veneer. We’ve seen a noticeable drop in material waste, and the ±0.5mm precision is consistent across 3m panels. The folding arm handles curved cabinet edges flawlessly, which was a bottleneck before. Setup was smooth, and the operator found the interface intuitive with minimal training."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Bespoke Woodworking Studio

"As someone who works on custom curved furniture pieces, finding a machine that handles irregular shapes without sacrificing finish quality was critical. The adjustable folding arm on the W2 has been a game-changer. I purchased the Advanced Model in October 2024, and after 7 months of near-daily use, it’s performed flawlessly. The ability to save custom presets for different veneers means I can switch from oak to walnut banding in minutes. It’s industrial-grade power with artisan-level control."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Lin - Operations Manager, Elite Furniture Co.

"We integrated two Pro Model W2 machines into our factory in January 2025 to handle high-volume orders for luxury bedroom sets. The ±0.1mm accuracy and 1.56 kW power output allow us to process hardwood veneers quickly without burn marks or misalignment. The 380V compatibility was a plus—no need for converters. My only minor critique is the floor space required, but that’s expected for a machine handling up to 5m panels. Maintenance has been straightforward thanks to the modular design and 6-month service reminders."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Anita Patel - Woodcraft Workshop Owner

"I was hesitant about upgrading from our old edge bander, but the W2 Base Model has exceeded expectations. Purchased in November 2024, it’s now been our go-to for both standard and curved kitchen cabinet panels. The steel construction feels solid—no vibrations even at high speeds. The CE certification gave me peace of mind for workplace safety compliance. Best of all, the 1-year warranty and responsive support team helped resolve a minor calibration hiccup within 24 hours."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Reed - Senior Technician, Heritage Woodworks

"We’ve tested several edge banding machines, but the W2 stands out for its scene adaptability. We use it for both batch production and one-off architectural millwork. The temperature control is precise enough to prevent scorching delicate veneers, and the folding arm adjusts smoothly for radius edges. I’d love to see a quieter motor in future models, but at 55 dBA, it’s still better than most competitors. After 4 months of use (purchased April 2025), reliability has been excellent."Purchase Date: April 2025 | Usage Period: 3 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Linda Cho - Industrial Woodworking Consultant

"The W2 Folding Arm Curve Edge Banding Machine sets a new benchmark for mid-to-high-tier production environments. Its combination of digital precision, folding arm flexibility, and robust steel build makes it ideal for workshops transitioning from manual to semi-automated processes. I particularly recommend the Advanced and Pro models for manufacturers focusing on curved-edge furniture, where consistency and edge finish are paramount."

Carlos Mendez - Production Engineering Specialist

"After evaluating edge banding systems across 12 factories, I can confidently say the W2 delivers exceptional value. The 380V direct integration reduces energy loss, and the modular servicing design minimizes downtime. For high-volume shops, the Pro Model’s fully automatic workflow and 5m panel support offer a clear ROI within 18 months."

Posted: 2 days ago

"Upgraded from a 220V model—what a difference 380V makes. Runs all day without overheating. The folding arm is smooth and accurate. Highly recommend for any serious shop."

Posted: 1 week ago

"We make custom curved office furniture, and the W2 handles every radius perfectly. Touchscreen presets save us hours weekly. Zero regrets."

Posted: 3 weeks ago

"Performance is excellent, but make sure you have room. It’s larger than expected, but worth it for the quality of finish."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.