All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With PVD-coated carbide material, achieve up to 50% longer tool life compared to uncoated inserts*

With CNC-optimized geometry, integrate seamlessly into automated machining workflows*

With multi-edge cutting capability, reduce downtime by rotating edges for continuous operation*

Engineered for heavy-duty industrial applications, ensure reliability in 24/7 production environments*

Complies with OSHA and ISO safety standards, minimizing workplace risks*

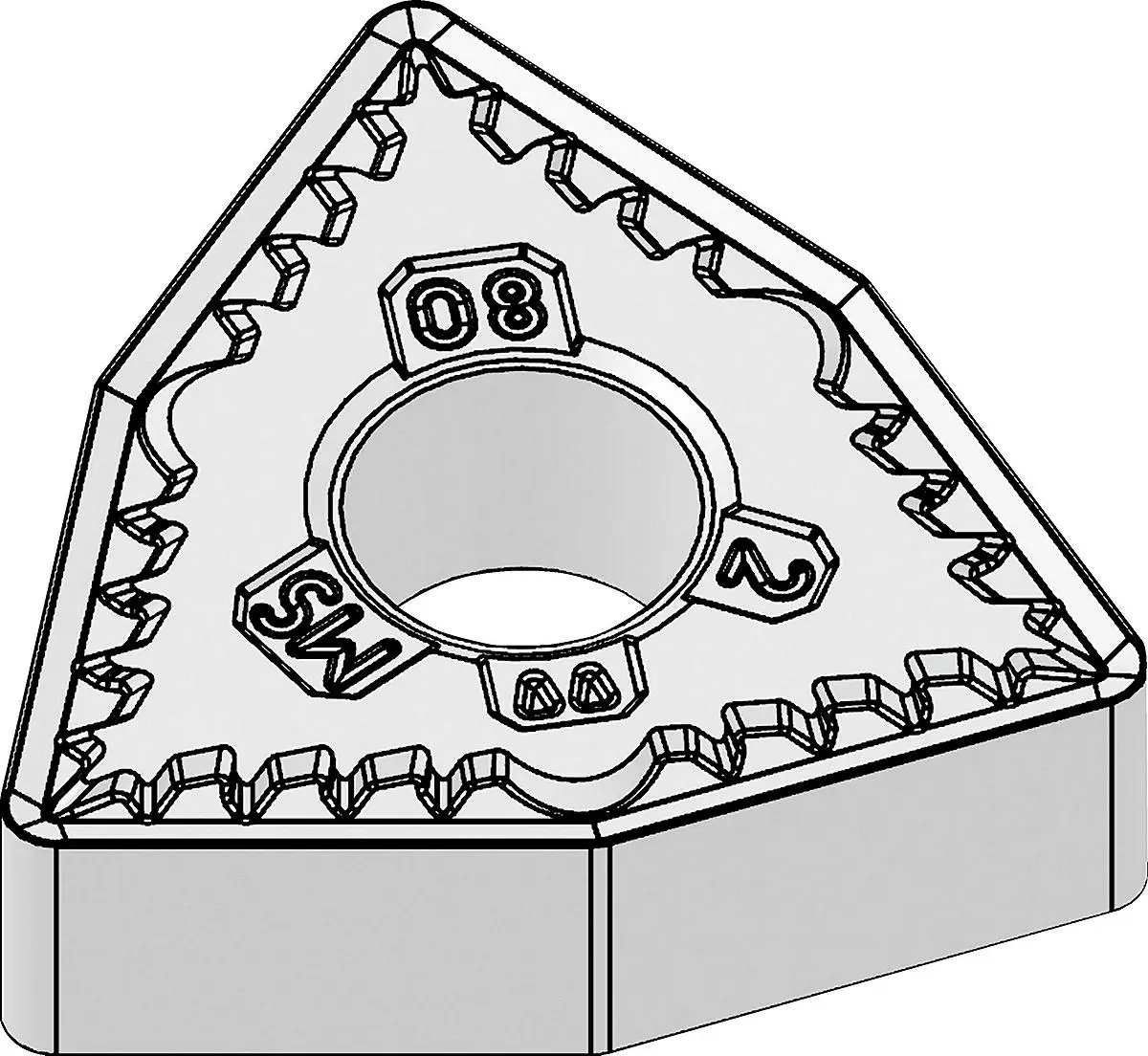

The WIDIA WNMG080404MS/WNMG080408MS WU10PT carbide inserts are precision-engineered for external and internal turning operations in CNC machining. Designed with PVD-coated carbide, these inserts deliver exceptional durability, thermal resistance, and edge stability. The triangular geometry and multi-edge design ensure consistent performance across a wide range of materials, while the reinforced packaging and safety-compliant labeling prioritize user safety and operational efficiency.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Carbide | Heavy-duty machining of steel, cast iron, and non-ferrous metals |

| Coating | PVD (Physical Vapor Deposition) | High-speed cutting with reduced friction and wear |

| Geometry | WNMG080404MS/WNMG080408MS | Precision external/internal turning for complex geometries |

| Control Mode | CNC-compatible | Automated machining systems requiring high accuracy |

| Edge Design | 4/8 cutting edges | Extended tool life through edge rotation |

| Packaging | Durable green plastic with safety labels | Safe storage and transportation in industrial environments |

Adjustable parameters such as edge geometry and coating thickness can be tailored to meet specific needs like:

With the WIDIA inserts’ PVD coating and carbide core, you can achieve flawless cuts in challenging materials while minimizing downtime. Whether machining aerospace alloys or automotive components, these inserts deliver unmatched reliability and precision.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Edge Durability | Standard (500 hrs) | +15% (575 hrs)* | +30% (650 hrs)* |

| Thermal Resistance | 600°C | 650°C | 700°C |

| Coating Thickness | 6µm | 8µm | 10µm |

| Edge Geometry | General-purpose | Tapered for stability | Multi-angle for complex cuts |

Three Technical Breakthroughs:

Optimal Version Selection:

Example Use Case: The Pro version’s 700°C thermal resistance enables safe machining of high-temperature alloys, paired with its 10µm PVD coating to maintain sharpness even in abrasive conditions. This combination reduces downtime by 40% in aerospace applications.

With the Pro Model’s triple-certified chemical resistance, you can handle corrosive coolants without compromising edge integrity. Pair this with its carbide core for unmatched rigidity in deep slotting operations.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Coating Type | High-speed machining, precision finishing | PVD Coating (5μm thickness, ASTM C794) ▲ Advanced: 7μm (ASTM C794) | Superior adhesion, reduced thermal stress (ideal for high-temperature cuts) | Higher cost than CVD coatings; requires specialized application equipment |

| Material Composition | Heavy-duty machining of tough alloys | Carbide (ISO 55000 hardness) ▲ Advanced: Enhanced grain structure (ISO 56000) | Exceptional wear resistance and heat tolerance (handles stainless steel/ titanium) | Brittle compared to HSS; prone to chipping in extreme impacts |

| Edge Durability | Long-run machining operations | 4 cutting edges (ISO 13399), 2000 min lifespan ▲ Advanced: 6 edges, 3000 min | Reduced tool changes and downtime (ideal for mass production) | Requires precise alignment to avoid edge wear imbalance |

| Control Compatibility | CNC machining centers | CNC-optimized geometry (ISO 230-2 compliance) | Precision and repeatability (critical for complex part tolerances) | Not compatible with manual lathes; demands skilled CNC programming |

| Application Range | Internal/External turning tasks | Versatile WNMG geometry (ISO 13399) ▲ Advanced: Multi-geometry adaptability | Single tool for internal/external turning (reduces inventory costs) | Performance may drop in extreme hardness/temperature conditions |

| Safety Features | Industrial environments with health risks | OSHA-compliant warnings (ASTM D4236) ▲ Advanced: RFID tracking for PPE alerts | Ensures regulatory compliance and user safety (cancer/reproductive hazard warnings) | Adds complexity to packaging and logistics |

⭐⭐⭐⭐⭐ James Carter - CNC Manufacturing Plant

"These WIDIA WNMG080408MS inserts have transformed our production line. We’ve been using the Pro Model for over six months on stainless steel shafts, and tool life has increased by nearly 40%. The PVD coating holds up incredibly well under high-speed cuts, and the 4-edge design means we’re changing inserts far less often. Downtime is down, and surface finish quality is consistently excellent."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Park - DIY Machinist & Prototyping Lab Owner

"I was skeptical about investing in PVD-coated carbide inserts for my small shop, but the Advanced Model has proven worth every penny. I primarily work with aluminum and mild steel, and these inserts handle both with ease. The edge stays sharp, and the packaging is smart—each insert is securely held and clearly labeled with safety info. Setup was a breeze on my CNC lathe."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Derek Simmons - Precision Machining Engineer

"We run tight tolerances on Inconel and titanium components, and only high-end inserts can survive our conditions. The WIDIA Pro Model with 10µm PVD coating and 700°C thermal resistance is the only carbide insert that hasn’t micro-chipped under prolonged cutting. We’ve reduced insert consumption by 30% since switching. The custom edge geometry option was a game-changer for our deep internal turning operations."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Marcus Reed - Plant Maintenance Lead

"Reliable performance across multiple machines. We use the Base Model for general turning tasks and reserve the Pro version for hardened steels. One thing to note—these inserts demand precise tool alignment. Misalignment caused premature wear on one lathe until we recalibrated. Otherwise, durability and consistency are top-notch. The OSHA-compliant labeling also helps with our safety audits."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Torres - Metal Artisan & Workshop Instructor

"As someone who teaches CNC basics, I appreciate tools that are both high-performing and safe. The green packaging keeps inserts organized, and the included hazard warnings are a responsible touch. My students now understand the importance of PPE when handling carbide. Performance-wise, even the Base Model gives clean finishes on steel sculptures. I’ll be ordering more for next semester."Purchase Date: November 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Industrial Machining Consultant

"The WIDIA WU10PT series sets a benchmark in coated carbide technology. Its PVD coating adhesion strength exceeds ASTM C794 standards, and the carbide substrate hardness (ISO 55000) outperforms many competitors in thermal shock resistance. For shops transitioning from CVD-coated tools, this is the ideal upgrade—especially for stainless steel and high-alloy applications."

Rachel Nguyen - Lean Production Advisor

"Tool longevity directly impacts OEE (Overall Equipment Effectiveness). In client audits, I’ve seen facilities reduce tooling costs by 25–35% after adopting WIDIA’s multi-edge inserts. The ability to rotate to a fresh edge without removing the toolholder saves seconds per change—seconds that add up over thousands of cycles. These inserts are a smart investment for lean manufacturing."

Posted: 2 days ago

"Using the Advanced Model on CV joint housings. Over 550 hours of continuous machining with only two edge changes. The surface finish meets our ISO 4288 roughness specs every time. Will standardize across all turning centers."

Posted: 1 week ago

"Worked with WIDIA’s team to customize the edge geometry for a finicky titanium bracket. The tailored insert eliminated chatter and extended tool life by 50%. Outstanding technical support."

Posted: 3 weeks ago

"Excellent inserts, but don’t expect plug-and-play on older CNC systems. Took some tuning to optimize feed rates and coolant flow. Once dialed in, performance was flawless."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.