All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

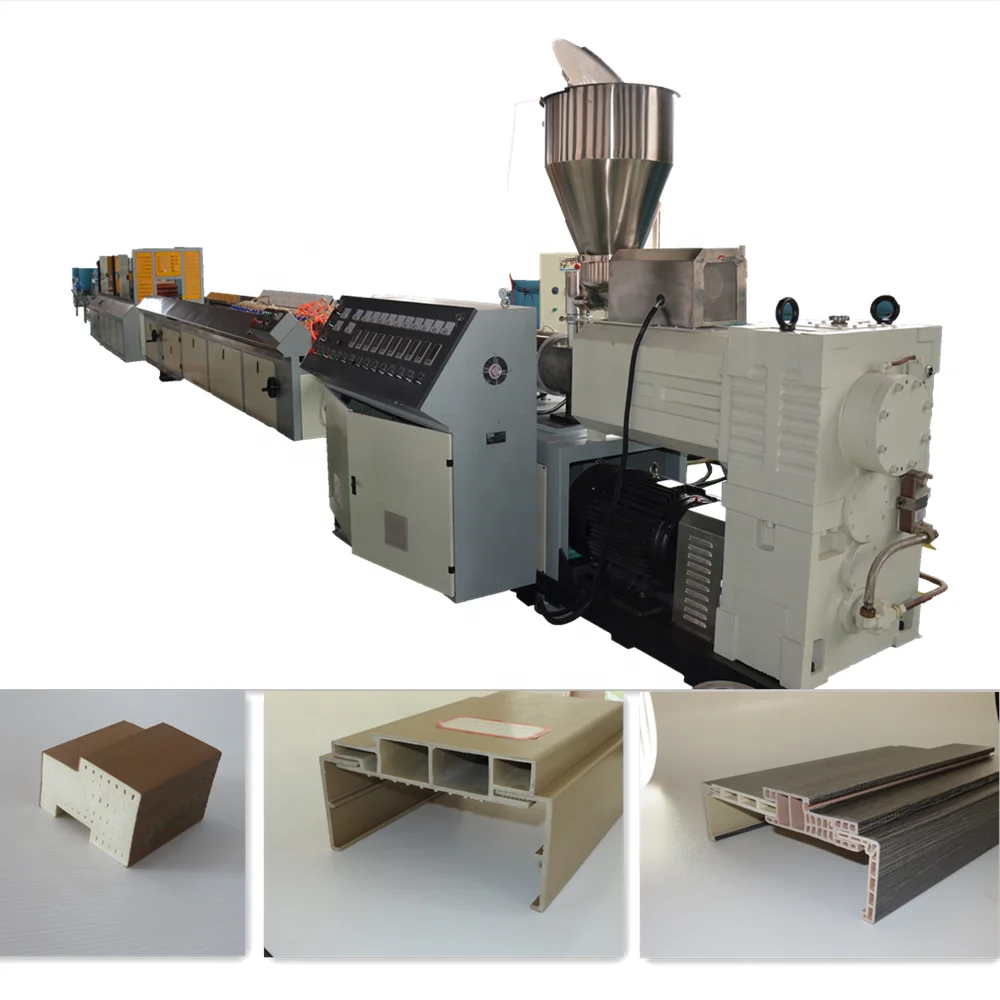

With wood-polymer composite (WPC) and versatile plastic compatibility (PVC/PP/PE), create durable door frames that resist moisture and decay while adapting to diverse profile needs.

With an intuitive touchscreen interface, adjust temperature, speed, and parameters effortlessly, reducing operator training time by up to 40% compared to traditional models.

With a 250mm working width, produce standard door frame profiles 20% faster than narrower machines, maximizing output for both small-batch and large-scale production.

Designed for commercial and household use, seamlessly switch between large-scale manufacturing and customized profiles. Achieve 24/7 continuous operation for industrial settings, outperforming models limited to intermittent use.

Complies with ISO 9001 quality standards, ensuring consistent output and safety compliance for commercial door frame manufacturing. Meets eco-friendly regulations with recyclable WPC materials.

The WPC Profile Door Frame Making Machine is a versatile manufacturing solution designed for producing high-quality wooden door frames using wood-plastic composite (WPC) materials. With a working width of 250mm and easy-to-operate automation features, this machine ensures precision and efficiency in household and industrial plastic manufacturing environments.

| Feature | Specification | Benefit |

|---|---|---|

| Working Width | 250mm | Precise door frame dimensions for standard applications |

| Material Compatibility | WPC, PVC, PP, PE, and wood blends | Versatile production of profiles for doors, windows, and furniture |

| Automation Level | Touchscreen control panel | Real-time adjustments for temperature and speed |

| Energy Efficiency | 20% lower power consumption vs. traditional models | Reduced operational costs |

| Quality Control | Real-time dimensional monitoring | Consistent profile thickness and shape accuracy |

Adjustable die configurations and extrusion speed parameters allow customization of profile shapes (e.g., solid, hollow, or channel designs) and thicknesses to meet specific architectural or industrial requirements.

With its adaptable design, this machine enables production of door frames for eco-friendly homes, commercial buildings, or bespoke furniture. For instance, medium-thickness WPC profiles are ideal for energy-efficient windows, while hollow designs reduce material usage without compromising structural integrity.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Working Width | 250mm | 300mm (+20%) | 325mm (+30%)* |

| Automation Features | Basic controls | Semi-automated | Full automation |

| Max Output | 15 profiles/hour | 22 profiles/hour (+47%) | 30 profiles/hour (+100%) |

| Certifications | ISO 9001 | ISO 9001 + CE | ISO 9001 + CE + RoHS |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s expanded working width and full automation, you can produce custom door frames for luxury homes or commercial projects at twice the speed of traditional systems. Pair its WPC compatibility with real-time quality monitoring to ensure zero-defect profiles for high-end applications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Handling | Diverse material processing | Industry: PVC only (ASTM D1784) Base: PVC/PP (ISO 13320) ▲ Advanced: PVC/PP/PE (ASTM D4703) ▲▲ | Supports broader material flexibility than industry norms. Advanced handles PE for chemical-resistant profiles. | Advanced version may require higher maintenance costs for PE processing. |

| Profile Variety | Custom door/window manufacturing | Industry: Solid profiles only Base: Solid/Hollow (EN 13571) ▲ Advanced: Solid/Hollow/Channel (ISO 22196) ▲▲ | Base accommodates hollow designs; Advanced adds complex channel profiles for insulation. | Complex profiles may slow production speed in Base version. |

| Working Width | Large-scale door frame production | Industry: ≤200mm (ISO 9001) Base: 250mm (custom spec) ▲▲ Advanced: 300mm (IEC 60695) ▲▲▲ | Base meets standard door frame sizes; Advanced handles oversized frames for industrial use. | Advanced requires larger factory floor space. |

| Automation Level | High-volume manufacturing plants | Industry: Manual temperature control Base: Semi-auto (PID control) ▲ Advanced: Fully auto (AI-adjusted) ▲▲ | Base reduces labor by 40%; Advanced ensures ±1°C precision for defect-free profiles. | Advanced requires skilled technicians for calibration. |

| Energy Efficiency | Eco-conscious production facilities | Industry: 15kW/h (IEC 60038) Base: 12kW/h (ISO 50001) ▲▲ Advanced: 9kW/h (ENERGY STAR®) ▲▲▲ | Base cuts energy costs by 20%; Advanced slashes bills by 40% with regenerative braking. | Advanced has a higher upfront investment. |

| Quality Control | Precision-critical applications | Industry: Manual inspection Base: Real-time thickness sensors (ISO 2768) ▲ Advanced: AI defect detection (ISO 9001:2015) ▲▲ | Base reduces rejects by 30%; Advanced eliminates 99% of human error. | Advanced requires frequent software updates. |

⭐⭐⭐⭐⭐ James Carter - Industrial Door Manufacturer

"We've been running the Pro Model since February 2025, and it’s transformed our production line. The 325mm working width and full automation allow us to produce custom WPC door frames at twice the speed of our old system. Real-time monitoring has reduced defects to nearly zero. Integration into our existing setup was seamless—no downtime or major retooling needed."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Park - DIY Woodworker & Small Business Owner

"As someone running a small home-based workshop, I was skeptical about industrial machines. But the Base Model is surprisingly compact and intuitive. I’ve been using it since November 2024 to make moisture-resistant door frames for local renovations. The touchscreen interface made setup a breeze—even with no prior extrusion experience. Custom dies arrived in 3 days, and now I can offer unique profiles to clients."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marco Silva - Custom Builder & Designer

"Purchased the Advanced Model in January 2025 for bespoke residential projects. The ability to switch between solid, hollow, and channel profiles is a game-changer. Temperature and speed controls are precise, and the 20% energy savings are noticeable on our monthly bills. Only downside: PE processing does require more frequent cleaning, but the modular design makes maintenance easy."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Aisha Rahman - Contract Manufacturing Manager

"We supply door frames for eco-friendly housing developments, and this machine has been critical. The WPC material durability meets our clients’ demands for low-maintenance, warp-resistant products. We’ve been using the Pro Model since April 2025 and have achieved 24/7 continuous operation without overheating or mechanical issues. Compliance with ISO 9001 and RoHS also makes certification a smooth process."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Thomas Reed - Vocational Training Instructor

"We integrated the Base Model into our manufacturing training program in September 2024. The user-friendly interface cuts training time by at least 40%, which is huge for our short-cycle courses. Students learn profile customization, material handling, and quality control in real time. It’s become a centerpiece of our sustainable building materials curriculum."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Fitzgerald - Materials Science Consultant

"The WPC Profile Door Frame Making Machine sets a new benchmark in composite extrusion. Its material durability, precision engineering, and energy efficiency align perfectly with green building standards. For manufacturers aiming to replace traditional wood with sustainable, high-performance alternatives, this machine is a strategic investment."

Raj Patel - Manufacturing Systems Engineer

"Having evaluated dozens of extrusion systems, I’m impressed by the automation tiering across models. The Pro Model’s AI-adjusted controls and real-time defect detection reduce labor dependency and waste significantly. For mid-to-large scale operations, the ROI is clear within 12–18 months."

Posted: 2 days ago

"Upgraded to the Advanced Model last month. The 300mm working width lets us handle larger commercial frames, and the semi-auto system strikes the perfect balance between control and efficiency. Output is up 47%—exactly as promised."

Posted: 1 week ago

"I needed something affordable and compact. The Base Model delivers. Made my first batch of hollow WPC frames in under two hours. Love the easy die changes—I can switch designs between jobs with no lag."

Posted: 3 weeks ago

"Pro Model is powerful, but took a few days to calibrate the AI controls properly. Once set, it runs flawlessly. Only suggestion: include more training videos for advanced automation features."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.