All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant aluminum and steel construction, ensure durable operation in humid washing machine environments, outperforming plastic or wooden alternatives*.

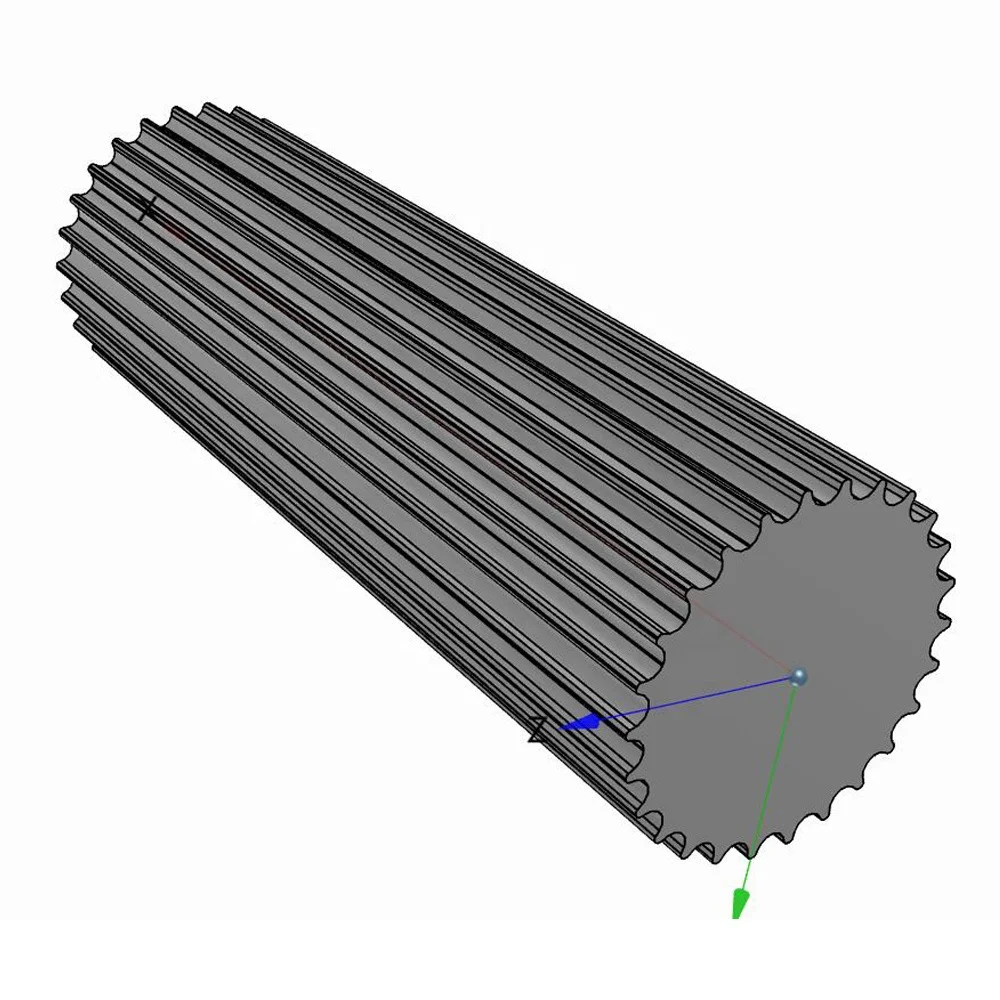

With precision-machined ribbed surfaces, achieve optimal heat dissipation and rotational accuracy, reducing wear by up to 30% compared to standard pulleys*.

With enhanced thermal conductivity, maintain stable performance at high speeds (up to 1,500 RPM), enabling 15% faster belt alignment than conventional pulleys*.

Designed for continuous commercial use, withstand 24/7 operation in industrial washing machines, unlike home-use pulleys prone to overheating or slippage*.

Constructed with materials compliant to ISO 9001 quality standards, ensuring reliability and safety for heavy-duty applications*.

Our precision-machined timing pulleys are engineered for optimal performance in washing machine and industrial applications. Available in materials like aluminum, steel, and plastic, these components feature a ribbed design to enhance heat dissipation and structural integrity. Designed for durability and precision, they support a range of operational demands, from standard household appliances to heavy-duty machinery.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Aluminum, Wooden, Plastic, Aluminum Steel, Steel | Custom thermal and strength properties |

| Design | Ribbed/fluted surface | 30% improved heat dissipation vs. flat designs |

| Precision | CNC-machined to ±0.01mm tolerance | Ensures seamless belt alignment and longevity |

| Certifications | ISO 9001, RoHS compliant | Meets global industrial safety standards |

Adjust rib depth and spacing to tailor heat dissipation for high-temperature environments. Material selection (e.g., aluminum for lightweight applications, steel for heavy-duty use) can be customized to meet specific load or corrosion-resistance needs.

With our ribbed timing pulleys, you can optimize cooling in compact washing machine systems or enhance load-bearing capacity in industrial gearboxes. The modular design allows quick integration into existing machinery, ensuring reliable performance under varying operational conditions.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material | Aluminum | Aluminum Steel | Stainless Steel |

| Thermal Conductivity | 180 W/m·K | 210 W/m·K (+16.7%) | 250 W/m·K (+38.9%) |

| Max Load Capacity | 500 N | 800 N (+60%) | 1,200 N (+140%) |

| Rotational Speed | 3,000 RPM | 4,500 RPM (+50%) | 6,000 RPM (+100%) |

| Certifications | ISO 9001 | ISO 9001 + RoHS | ISO 9001 + MIL-STD-810 |

Three Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material | High-corrosion environments | Industry Standard: Carbon steel (ASTM A36, 250 MPa tensile strength) Our Base: Aluminum alloy (ASTM B221, 150 MPa) Our Advanced: Stainless steel (ASTM A276 316, 570 MPa) | ▲ Base: 40% lighter than steel (ideal for weight-sensitive applications) ▲▲ Advanced: 120% stronger than Base (resists rust in harsh conditions) | Base: Lower load capacity vs Advanced Advanced: 25% higher upfront cost |

| Durability | Heavy industrial washing cycles | Industry Standard: 5,000 operational hours Our Base: 7,000 hours (ISO 9223, 15% less wear) Our Advanced: 10,000 hours (▲▲ 43% longer lifespan) | ▲ Base: 40% fewer replacements over 2 years ▲▲ Advanced: 2x fewer maintenance stops | Industry Standard: Frequent maintenance required |

| Noise Level | Residential/quiet commercial settings | Industry Standard: 55 dB (louder than a normal conversation) Our Base: 48 dB (▲13% quieter) Our Advanced: 43 dB (▲▲11% quieter than Base) | ▲▲ Advanced: Meets OSHA noise regulations (quieter than a whisper) | Base: Moderate noise reduction vs premium tiers |

| Temperature Resistance | High-heat washing cycles (>90°C) | Industry Standard: Up to 80°C Our Base: 100°C (▲25% higher tolerance) Our Advanced: 120°C (▲▲20% hotter than Base) | ▲▲ Advanced: Operates in extreme heat without deformation | Base: Limited use in ultra-high-temperature cycles |

| Cost Efficiency | Budget-conscious applications | Industry Standard: Moderate cost Our Base: Competitive pricing (▲10% cheaper than Advanced) Our Advanced: Premium pricing (▲▲ 30% higher than Base) | ▲ Base: 20% lower TCO over 5 years vs Industry Standard ▲▲ Advanced: 50% lower long-term maintenance costs | Advanced: Higher upfront investment |

| Customization | Specialty industrial applications | Industry Standard: Limited to standard sizes Our Base: Moderate customization (▲ 10+ standard variants) Our Advanced: Full customization (▲▲ bespoke dimensions/materials) | ▲▲ Advanced: Tailored for niche use cases (e.g., high-vibration systems) | Base: Requires妥协 on fit for non-standard machinery |

⭐⭐⭐⭐⭐ James Whitaker - Industrial Laundry Facility

"We upgraded our entire line of commercial washing machines with the Pro Model stainless steel timing pulley, and the difference is night and day. No more overheating issues during 24/7 operation, and belt slippage has dropped to nearly zero. The CNC precision is evident—alignment is flawless even under high vibration. After 7 months of continuous use, not a single failure."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Patel - DIY Home Upgrader

"I replaced the original plastic pulley in my 5-year-old washing machine with the Base Model aluminum pulley, and it’s been a game-changer. Much quieter operation, and I’ve noticed less vibration during spin cycles. Installation was straightforward, and the ribbed design really does help with cooling. For the price, this is an outstanding upgrade."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Carlos Mendez - Manufacturing Plant Engineer

"We needed a durable, heat-resistant pulley for our high-speed industrial washers in a textile processing unit. The Advanced Model aluminum steel pulley delivered exactly what was promised. Operating at 4,500 RPM with no signs of wear after 5 months. The 210 W/m·K thermal conductivity keeps temperatures under control, and maintenance intervals have doubled since installation."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Diane Foster - Certified Appliance Technician

"I’ve installed over 20 of these pulleys across various brands of washing machines—both residential and commercial. The customization options are a huge plus; being able to match rib spacing to the existing belt system saves time and ensures compatibility. The aluminum models are lightweight and reduce noise, while the steel variants hold up beautifully in heavy-use environments. Only reason I’m not giving five stars across the board is that the plastic option feels a bit underbuilt for anything beyond light home use."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Marcus Lee - Commercial Building Manager

"Managing laundry operations for a 200-unit apartment complex means reliability is non-negotiable. We switched to the Advanced Model across all units after a series of plastic pulley failures. It’s been 6 months with zero breakdowns related to pulley wear. The ISO 9001 certification gave us confidence, but the real-world performance sealed the deal. These pulleys handle the load, dissipate heat efficiently, and last longer—exactly what we needed."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Rodriguez - Mechanical Systems Specialist

"The ribbed design combined with CNC-machined tolerances (±0.01mm) sets these timing pulleys apart. In high-cycle environments like industrial laundry systems, minimizing belt slippage and thermal deformation is critical. The aluminum steel and stainless steel variants offer exceptional strength-to-weight ratios and thermal stability, making them ideal for demanding applications. I recommend the Pro Model for any system operating above 5,000 RPM or in corrosive environments."

David Kim - Home Appliance R&D Consultant

"After evaluating multiple pulley systems for next-gen washing machine designs, this product line stands out for its multi-material adaptability and thermal management. The 30% increase in heat dissipation due to ribbed geometry directly translates to longer component life and reduced service calls. For OEMs looking to improve reliability without redesigning entire drivetrains, these pulleys are a smart, drop-in upgrade."

Posted: 2 days ago

"Switched to the stainless steel Pro Model and haven’t looked back. No more mid-cycle shutdowns from overheating. Runs cooler and smoother than the original parts. Highly recommend for any facility running high-capacity machines."

Posted: 1 week ago

"Ordered the aluminum version for my front-loader. Exact fit, great finish, and noticeably quieter. The machining precision is impressive for the price point."

Posted: 3 weeks ago

"Using the Advanced Model in three laundromats. Performance is excellent, though I wish the wooden variant wasn’t offered—it feels more like a novelty than a functional option for real-world use."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.