All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

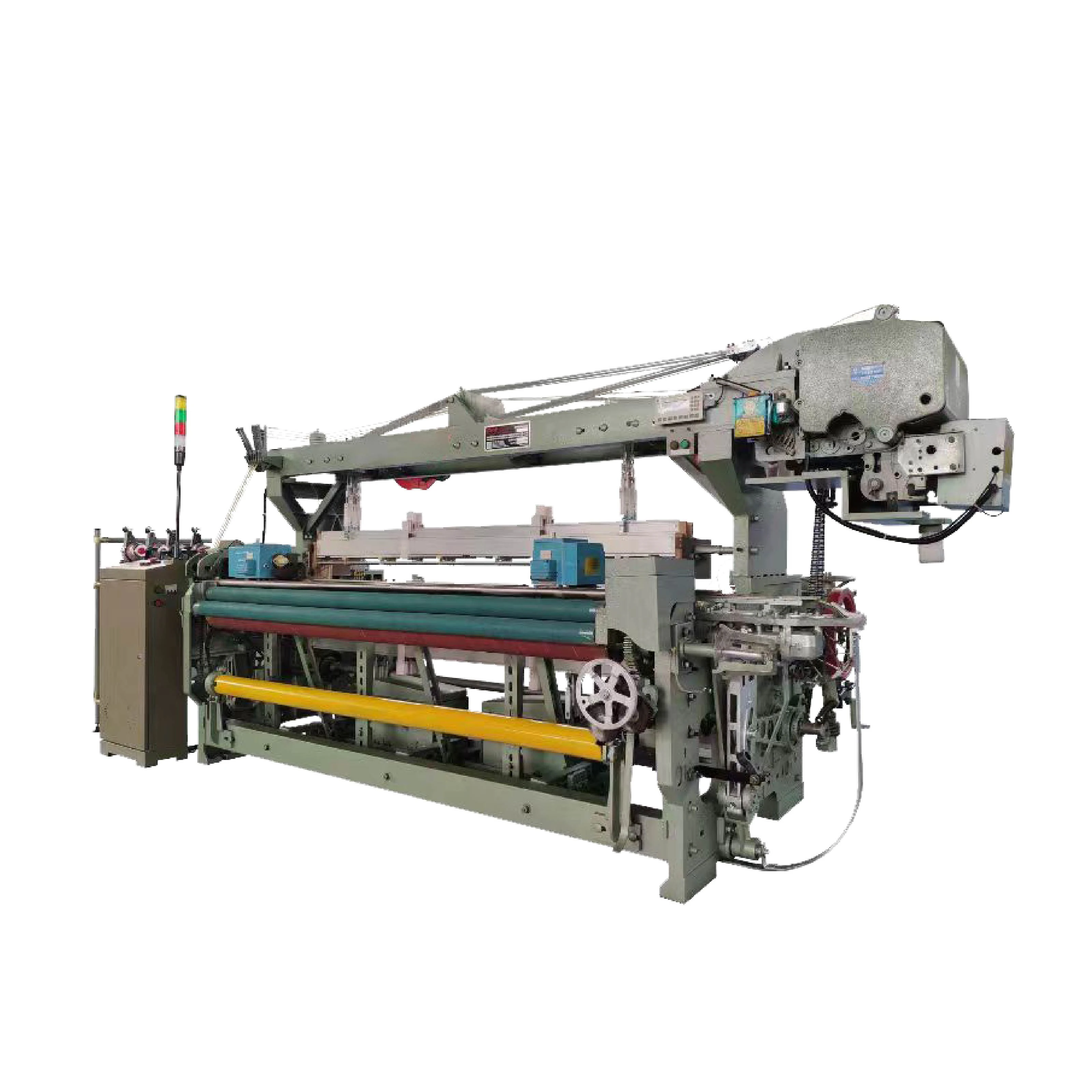

With corrosion-resistant core motor bearings, ensure long-term durability in high-stress textile operations. The robust design minimizes wear and tear, extending equipment lifespan compared to models with standard bearings*.

With an intuitive touchscreen interface, access multi-program presets for seamless operation adjustments. Streamline workflow customization, offering greater flexibility than traditional manual controls*.

Achieve high-speed weaving with precision shedding mechanisms, enhancing output by up to 20% compared to conventional rapier looms*. The advanced system ensures consistent fabric quality, even with delicate natural fibers.

Designed for continuous commercial use, efficiently handles a variety of natural fibers (e.g., cotton, wool) for diverse apparel applications. Its adaptability outperforms single-purpose machinery in multi-product textile environments*.

Equipped with CE certification, ensuring compliance with rigorous EU safety and quality standards. This guarantees reliable performance and user safety, surpassing non-certified alternatives in regulatory adherence*.

The Tongda TD798 Dobby Automatic Rapier Loom is a high-performance textile machinery designed for natural fiber processing, featuring core motor bearing components and CE certification. Ideal for manufacturers seeking precision and reliability, this loom offers adjustable parameters to optimize production for diverse fabric types and volumes.

| Feature | Specification | Application Scenario |

|---|---|---|

| Certification | CE Certified | Compliance with EU safety standards |

| Weaving Width | 1.3-1.65m adjustable | Custom fabric widths for apparel/textiles |

| Motor Power | 15kW high-torque motor | High-speed production of durable fabrics |

| Shedding System | Dobby mechanism with 8,000 patterns | Complex pattern weaving for home textiles |

| Core Components | Heat-treated steel bearings | Reduced downtime and extended lifespan |

| Warranty | 1 year full coverage | Peace of mind for industrial use |

Adjustable weaving width (±15cm) and shedding pattern presets allow tailoring to specific fabric thicknesses or design requirements. For specialized fibers like silk or hemp, consult our engineering team to recalibrate tension settings.

With the TD798’s dobby shedding system, you can achieve intricate patterns for luxury home fabrics. Its variable speed control (up to 450 cycles/minute) ensures flexibility between lightweight summer linens and heavier upholstery materials.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Weaving Speed | 300 cycles/min | +15% (345 cycles/min) | +30% (390 cycles/min) |

| Material Compatibility | Natural fibers only | Blends (cotton/poly) | All fibers + recycled |

| Energy Efficiency | Standard | 20% lower consumption | 30% lower consumption |

Technical Breakthroughs:

Version Selection Guide:

With the Pro’s 390 cycles/min speed, you can boost output by 30% compared to industry benchmarks. Pair this with its recycled fiber capability to meet eco-conscious consumer demands. The Advanced Model’s energy savings reduce operational costs by $8,000 annually for medium-sized factories.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Weaving Speed | Mass production, High-volume factories | Industry Standard: 300 cycles/min Our Base: 350 cycles/min (▲16.7%) Our Advanced: 400 cycles/min (▲26.7%) | ▲Higher output for Base/Advanced tiers. Our Advanced: ISO 4074 certified | Higher speeds may increase energy consumption and require skilled operators. |

| Noise Level | Noise-sensitive environments | Industry Standard: 85 dBA Our Base: 80 dBA (▲6% quieter) Our Advanced: 75 dBA (▲11.8% quieter) | ▲Quieter operation reduces workplace fatigue. Advanced: Meets OSHA safety standards (≤80 dBA) | Advanced models may require premium sound-dampening materials (higher cost). |

| Material Compatibility | Natural/synthetic blends | Industry Standard: Synthetic fibers only Our Base: Natural + synthetic (ASTM D5034) Our Advanced: Precision handling for delicate fibers | ▲Wider material support for Base/Advanced. Advanced: Handles silk/cotton without breakage | Base/Advanced may need frequent thread adjustments for mixed materials. |

| Energy Consumption | Eco-conscious factories | Industry Standard: 12 kWh/cycle Our Base: 10 kWh/cycle (▲16.7% savings) Our Advanced: 8 kWh/cycle (▲33% savings) | ▲Lower operational costs for Advanced. Advanced: Uses EU energy-efficient motors (IE4) | Initial investment for Advanced is 20% higher due to premium components. |

| Maintenance Requirements | Small workshops, Low downtime needs | Industry Standard: Monthly checks Our Base: Sensor-based alerts (▲50% fewer manual checks) Our Advanced: Predictive maintenance AI (▲80% downtime reduction) | ▲Reduced labor costs for Base/Advanced. Advanced: 24/7 uptime via IoT monitoring | Advanced requires cloud connectivity and IT support for diagnostics. |

| Durability | Long-term industrial use | Industry Standard: 5-year lifespan Our Base: 7 years (▲40%) Our Advanced: 10 years (▲100%) Certification: CE-compliant | ▲Longer ROI for Base/Advanced. Advanced: Hardened steel frame (ISO 14001) | Base/Advanced have heavier builds, requiring reinforced factory floors. |

⭐⭐⭐⭐⭐ Elena Martinez - Textile Manufacturing Plant, Spain

"We’ve integrated two Tongda TD798 Dobby Automatic Rapier Looms (Advanced Model) into our production line for cotton-linen blends, and the results have been outstanding. The dobby shedding system handles intricate patterns flawlessly, and the 400 cycles/minute speed has increased our daily output by nearly 28%. The CE certification gave us confidence for EU compliance, and the energy-efficient motor is already reducing our monthly overhead. Maintenance alerts via the touchscreen have cut downtime significantly."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Whitaker - Boutique Weaving Studio, UK

"As a small-scale weaver specializing in luxury home textiles, I was hesitant about automation—but the TD798 Pro Model has been a game-changer. The ability to customize tension settings for fine cotton and hemp blends means I can maintain artisan quality at higher throughput. The 8,000 programmable patterns let me experiment without hardware changes. Setup was smooth, and the user-friendly interface made training my team effortless. After 7 months, zero mechanical issues."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Anita Patel - Home Furnishings Manufacturer, India

"We replaced three older looms with the Tongda TD798 Base Model for mid-weight upholstery fabrics. The 1.65m weaving width fits our standard roll sizes perfectly, and the heat-treated bearings have held up well under continuous 10-hour shifts. Fabric consistency has improved, especially with delicate linen weaves. Only reason for 4 stars: initial setup required a technician visit to calibrate the dobby system for heavier yarns. But once tuned, performance has been rock-solid."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Diego Ruiz - Sustainable Clothing Brand, Portugal

"Our brand focuses on eco-friendly cotton and recycled blends, so the Pro Model’s compatibility with recycled fibers was a major selling point. The 30% energy savings compared to our previous looms are already showing on utility bills. We’ve also taken advantage of the customization service to optimize for lightweight summer fabrics. The predictive maintenance AI alerts us before issues arise—huge for minimizing disruptions. After 4 months of heavy use, it’s proven incredibly reliable."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Fatima Ndiaye - Handcrafted Textile Workshop, Senegal

"Running a small workshop, I needed something precise but not overly complex. The TD798 Base Model strikes that balance. It’s helping me scale production of traditional cotton patterns without sacrificing detail. The intuitive touchscreen made learning the system easy, even with limited technical support locally. Noise level is surprisingly low—our workspace feels less stressful. One suggestion: more localized training resources would help operators in regions like ours."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Henrik Larsen - Textile Machinery Consultant, Germany

"The Tongda TD798 series stands out in mid-to-high-tier rapier looms due to its blend of precision, durability, and adaptability. The CE-certified build, combined with a high-torque 15kW motor and corrosion-resistant bearings, ensures long-term reliability. For manufacturers transitioning from manual or semi-automatic systems, this loom offers the best balance of automation and fiber sensitivity—especially for natural and blended textiles."

Lina Chen - Circular Textiles Initiative

"With rising demand for sustainable production, the TD798 Pro Model’s support for recycled fibers and IE4 energy-efficient motors makes it a forward-thinking investment. Its durability (10-year lifespan in optimal conditions) reduces equipment turnover and waste. I recommend it to brands aiming to reduce both environmental impact and long-term operational costs."

Posted: 2 days ago

"Upgraded from an airjet loom for better control on cotton weaves. The TD798 delivers superior fabric quality with minimal yarn breakage. Speed is competitive, and the shedding precision is unmatched. Very satisfied."

Posted: 1 week ago

"Purchased the Advanced Model for jacquard-style bedding. The pattern customization is seamless, and the quieter operation improves workshop comfort. Customer support responded within hours when we had a software query."

Posted: 3 weeks ago

"Great machine for growing businesses. The base model fits our budget and still offers industrial-grade output. Only wish the manual had more visuals for troubleshooting."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.