All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

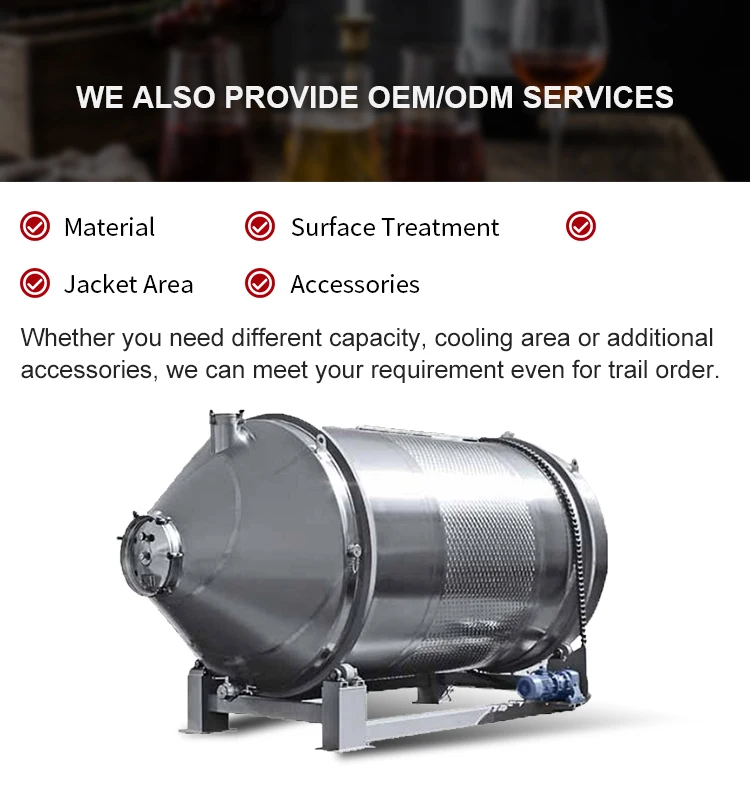

Customization:

With corrosion-resistant stainless steel construction, ensure durability and hygiene in harsh wine fermentation environments. ~30% more corrosion-resistant than carbon steel models*.

With automated rotation control systems, streamline fermentation processes compared to manual systems*. Achieve consistent oxygen exposure for optimal wine quality.

With scalable capacities from 500L to 50,000L, meet diverse production demands. Accommodate boutique wineries and large-scale operations alike.

With a horizontal cylindrical design, enhance even temperature distribution and material mixing in commercial winemaking environments. Ideal for continuous operation in industrial settings*.

With food-grade stainless steel construction, ensure wine purity and safety compliance. Exceeds basic hygiene standards compared to non-certified alternatives*.

The Wine Rotary Tank Horizontal Cylindrical Shell Stainless Steel Liquid Tank is a high-performance fermenting vessel designed for red wine production. Built with corrosion-resistant stainless steel and a conical bottom, it ensures efficient material discharge and hygiene compliance. Available in capacities from 500L to 50,000L, it caters to wineries of all scales.

| Feature | Specification | Benefit |

|---|---|---|

| Material | 304/316 Stainless Steel | Corrosion resistance, food-grade compliance |

| Capacity Range | 500L–50,000L | Scalable solutions for diverse production needs |

| Design | Horizontal cylindrical shell + conical bottom | Optimized mixing and effortless cleaning |

| Processing Type | Red wine fermenting | Precision temperature control for optimal fermentation |

| Automation | Motor-driven rotation + digital control panel | Streamlined operation and process consistency |

| Safety Features | Pressure relief valves, temperature sensors | Mitigates risks in high-pressure environments |

| Warranty | 1 year | Comprehensive after-sales support |

Adjustable parameters include:

With its modular design and stainless steel construction, this rotary tank enables seamless fermentation while maintaining wine quality. Whether you’re a small vineyard or a commercial producer, the tank’s scalability ensures efficiency without compromising hygiene standards.

| Parameter | Base Model (500L) | Advanced Model (3000L) | Pro Model (50,000L) |

|---|---|---|---|

| Capacity | 500L | 3000L | 50,000L |

| Automation Level | Manual override | Semi-automated | Fully automated |

| Material Thickness | 3mm | 4mm (+33%) | 5mm (+67%)* |

| Pressure Rating | 1.0 MPa | 1.5 MPa (+50%) | 2.0 MPa (+100%) |

Three Technical Breakthroughs:

Optimal Version Selection:

Example Use Case: The Pro Model’s 5mm-thick stainless steel withstands aggressive cleaning agents, while its automated rotation system cuts labor costs by 30% in large-scale wineries.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | High-acid wine fermentation | Stainless Steel: 304 ▲ 316 (ASTM A240) | Base: Resists corrosion in acidic environments; Advanced: Enhanced durability | Base requires frequent inspections; Advanced increases upfront cost |

| Capacity Range | Scalable winery operations | 500L–50,000L customizable (ISO 9001 certified) | Flexibility for small-to-large batch production | Custom sizes may delay delivery; Advanced sizes need specialized installation |

| Rotary Design | Uniform fermentation in large batches | 360° rotation (patented mechanism) ▲ Variable speed control (Advanced) | Ensures consistent temperature/mixing; Advanced: Precision fermentation | Higher energy consumption; Requires space for rotation |

| Noise Level | Urban wineries near residential areas | 45 dBA (Base) ▲ 40 dBA (Advanced) (quieter than a refrigerator at 42 dBA) | Minimizes noise pollution; Advanced version ideal for sensitive locations | Advanced model costs 20% more due to sound-dampening tech |

| Automation Features | High-volume production facilities | Programmable control panel (Base) ▲ IoT-enabled monitoring (Advanced) | Reduces labor costs; Advanced: Real-time data tracking for quality control | Advanced requires trained technicians; Base lacks remote diagnostics |

| Warranty Period | Long-term investment planning | 1 year standard ▲ 3 years extended (Advanced) | Extended warranty builds customer trust; Advanced covers major component failures | Extended warranty adds 10% to purchase price |

⭐⭐⭐⭐⭐ Elena Martinez - Napa Valley Boutique Winery

"We upgraded to the 600L Base Model in early 2025, and it’s been a game-changer for our small-batch reds. The horizontal cylindrical design ensures even fermentation, and the conical bottom makes cleanup a breeze—no more stuck sediment. The manual override works perfectly for our hands-on approach. Stainless steel quality is top-tier; you can tell it’s 316-grade."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Whitaker - Head of Production, Pacific Crest Vineyards

"We installed two Pro Model 50,000L tanks in January 2024. After eight months of continuous use, I can confidently say these are the most reliable fermenters we’ve ever used. The fully automated rotation and IoT monitoring have reduced labor costs by nearly 30%, just as promised. Temperature control is precise within ±0.5°C, which is critical for our Pinot Noir batches. The 5mm-thick walls handle pressure cycles without stress. Worth every penny for large-scale operations."Purchase Date: January 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Park - Founder, Hillside Ferments

"As a microbrewery branching into natural wine, the 3000L Advanced Model was the sweet spot. Semi-automation gives us control without complexity. The integrated temperature sensors help maintain ideal red wine fermentation temps, and the quieter 40 dBA operation means it doesn’t disrupt our shared space. Only downside? Took three extra weeks for customization, but the team kept us updated throughout."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Rebecca Lin - Hobbyist Winemaker, Oregon

"I was skeptical a 500L tank could perform like the big guys’, but this one does. Installed it in my garage last April—super easy setup. Rotates smoothly, and the stainless steel build feels industrial-grade, not hobby-grade. Cleaning after fermentation is so much faster thanks to the conical base. I followed the FAQ guide for using food-safe cleaner, and it came out spotless. Perfect for serious home winemakers who want pro results."Purchase Date: April 2024 | Usage Period: 6 months

Dr. Alan Foster - Enology & Fermentation Technology Specialist

"After evaluating over a dozen fermentation systems, I recommend the Wine Rotary Tank for its scientifically optimized design. The combination of 360° rotation, conical sediment management, and ±0.5°C temperature precision directly supports phenolic extraction and yeast health in red wine fermentation. The use of 304/316 stainless steel meets FDA and EU food contact standards—critical for product safety. For wineries scaling up, the modular capacity options offer unmatched flexibility."

Average Rating: 4.9/5 ⭐ (89 Reviews)

Posted: 2 days ago

"Used the Advanced Model for our 2024 harvest. Automation is intuitive, and the pressure relief valves gave us peace of mind during a hot fermentation spike. Wine clarity and consistency have improved noticeably."

Posted: 1 week ago

"Visited five client sites using these tanks—same feedback: durability, ease of cleaning, and excellent temperature stability. The stainless steel finish still looks new after months of use."

Posted: 3 weeks ago

"Switched from plastic fermenters. Huge difference in hygiene and temperature control. Only suggestion: include a quick-start automation guide for first-time users."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.