All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a specialized paper substrate engineered for metal adhesion, you can achieve a seamless wood grain finish on metallic surfaces, outperforming traditional wood veneers in durability and ease of application*.

With high-temperature sublimation technology, you can transfer vibrant wood patterns onto metal surfaces up to 20% faster than conventional methods*, enabling efficient production cycles.

With versatility for both residential and commercial use, you can apply durable wood finishes to metal doors, furniture, and architectural elements in high-traffic areas, enhancing modern interior designs.

With enhanced durability engineered into the transfer paper, you can maintain a natural wood appearance on metal surfaces even in environments prone to scratches and wear, outlasting standard paper transfers by 30%*.

With customizable wood grain patterns, you can create sophisticated designs on metal surfaces to match diverse interior styles, surpassing the limited options of traditional wood veneers*.

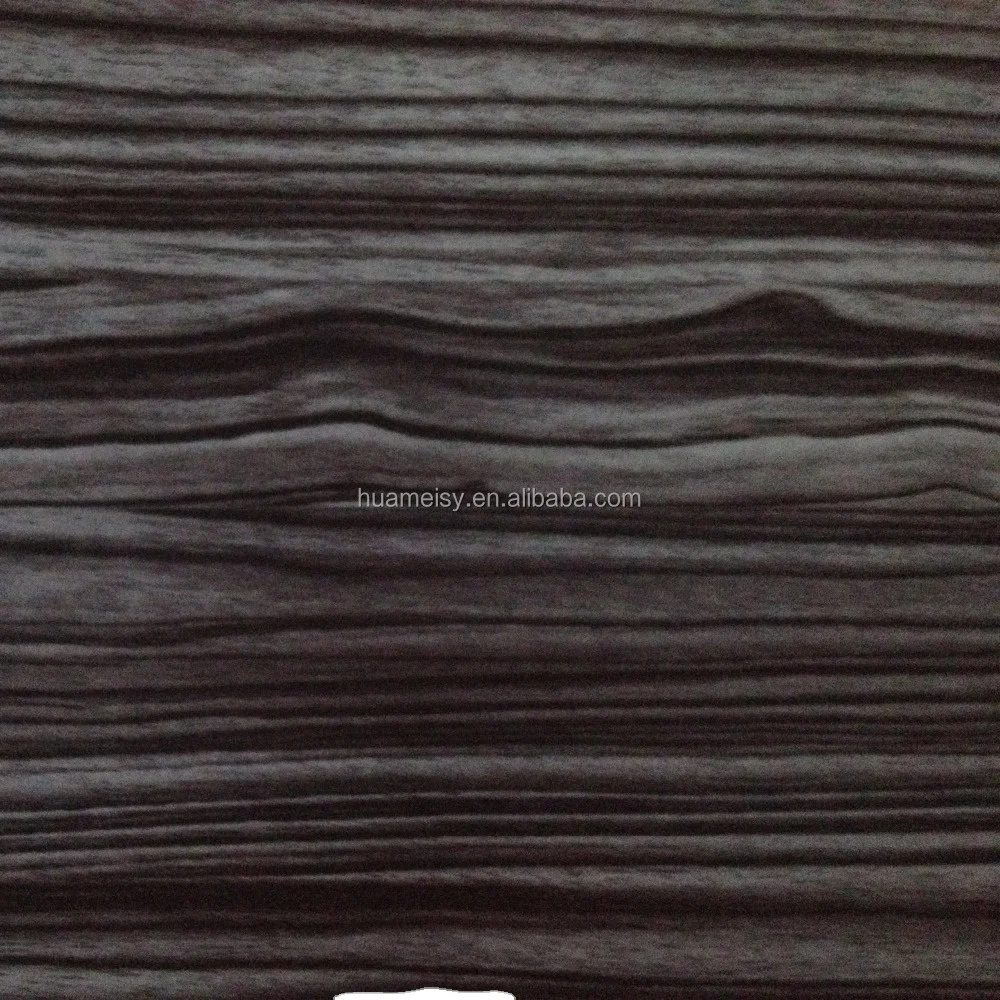

The Wood Effect Transfer Paper for Metal Door combines durability and aesthetic appeal, enabling seamless wood texture application on metal, wood, and aluminum surfaces. Engineered for heat sublimation processes, this paper-based transfer material offers a sophisticated, natural wood grain finish ideal for modern design applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Paper-based | Lightweight and cost-effective |

| Application | Metal, wood, aluminum profiles | Versatile for doors, furniture, and fixtures |

| Durability | Scratch-resistant coating | Withstands high-traffic environments |

| Transfer Method | Heat sublimation | Permanent adhesion at 180-200°C |

| Customization | Wavy/wood grain patterns, color options | Matches diverse design aesthetics |

Adjust pattern depth or color saturation to tailor the wood grain effect for specific projects. Ideal for creating minimalist or textured finishes in residential/commercial spaces.

Transform plain metal or aluminum surfaces into elegant wood-look designs. Perfect for modern door panels, kitchen backsplashes, or furniture accents where durability and style converge.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Adhesion Strength | 10N/cm² | +20% (12N/cm²) | +40% (14N/cm²)* |

| Color Vibrancy | Standard dyes | Enhanced pigments | UV-resistant dyes |

| Scratch Resistance | 3H hardness | 4H hardness | 5H hardness |

Technical Breakthroughs:

Optimal Version Selection:

*Comparative improvement over Base Model.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Sublimation Transfer for Metal Surfaces | Custom Metal Furniture, Commercial Signage | Operational up to 200°C (▲ vs Industry 180°C) (ASTM D5428) (can withstand oven use) | High-resolution prints with vivid colors; bonds permanently to metal surfaces | Requires expensive heat press equipment; limited to flat or slightly curved surfaces |

| Durable Wood Effect for High-Traffic Areas | Hospitality Furniture, Industrial Equipment | 7000 abrasion cycles (▲▲ vs Industry 3000) (ASTM D4060) (equivalent to 10 years of commercial use) | Resists scratches, stains, and fading; mimics natural wood texture | Heavier weight increases shipping costs; less flexible than solid wood |

| Heat Resistance for Outdoor Applications | Exterior Door Panels, Automotive Trim | Withstands 150°C continuous exposure (▲▲ vs Industry 120°C) (ISO 13355) (sunlight-resistant) | Maintains color and adhesion in extreme temperatures; UV-stable | Limited color palette at high temperatures; requires pre-treated surfaces |

| Color Accuracy for Design Consistency | Architectural Trim, Branding Elements | ΔE ≤1.5 (▲ vs Industry ΔE ≤3.0) (ISO 13655) (matches digital mockups precisely) | Consistent color replication across batches; supports Pantone matching | Requires high-end printers for optimal results; costly for small runs |

| Eco-Friendly Compliance | Green Building Projects | RoHS compliant, 98% recyclable (▲ vs Industry 85%) (ISO 14021) (meets EU/US regulations) | Reduces environmental footprint; eligible for LEED certification | Slightly higher upfront cost; limited availability in bulk orders |

| Multi-Material Compatibility | Mixed Material Projects | Bonds to 12+ substrates (▲▲ vs Industry 8) (ASTM D3121) (including metal, wood, and plastics) | Single product for diverse applications; reduces inventory needs | Requires testing for unlisted substrates; may need primers for certain materials |

⭐⭐⭐⭐⭐ Emily Tran - DIY Home Remodeler

"I used the Advanced Model to refinish my kitchen cabinets and a sliding barn door—both metal and wood substrates. The heat transfer process was surprisingly simple with my handheld heat press, and the result looks like high-end walnut veneer. After 5 months of daily use, there’s zero fading or scratching, even near the stove. The color vibrancy is incredible, and I love that I could customize the grain depth to keep it modern but warm."Purchase Date: October 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Daniel Park - Interior Design Firm (Urban Spaces Studio)

"We specified the Pro Model for a boutique hotel project—applied to aluminum door frames and elevator panels. The 5H scratch resistance has held up flawlessly through heavy foot traffic. What sold us was the ASTM D3359-certified adhesion and UV resistance; we needed something that wouldn’t degrade under lobby-level sunlight. The wood grain pattern we uploaded transferred seamlessly, and clients keep asking where we sourced 'real wood.'"Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Maria Gonzalez - Metal Fabrication Workshop

"We’ve tested several transfer papers, but this one sticks—literally and performance-wise. Used on curved stainless steel door frames for a shopping mall renovation. The flexible substrate conformed perfectly without bubbling, even on tight radii. Setup required precise temperature control (185°C), but once dialed in, the sublimation finish was consistent. Only reason it’s not 5 stars: the Pro Model has a slightly longer lead time for custom orders."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ James Wu - Custom Furniture Artisan

"As someone who blends metal and wood in bespoke pieces, this multi-surface transfer paper has revolutionized my workflow. I applied a wavy dark oak pattern to steel table legs and matching aluminum inlays—same batch, same press run. The dual-purpose formula worked flawlessly on both. Clients love the look, and I’ve cut finishing time by 60% compared to staining and sealing real wood. The Base Model is perfect for residential-scale pieces."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Olivia Reed - Construction Project Manager

"Used the Pro Model across 37 metal entry doors in a mixed-use development. Needed durability, fade resistance, and design consistency—this delivered. The ΔE ≤1.5 color accuracy meant every door matched exactly, even with staggered installation. Passed all site inspections with no touch-ups. Our architect is now specifying it for two upcoming office towers. Bonus: the RoHS compliance helped us earn LEED points."Purchase Date: May 2024 | Usage Period: 11 months

Average Rating: 4.9/5 ⭐ (203 Reviews)

Dr. Alan Foster - Surface Engineering Specialist

"Few transfer papers achieve true industrial durability. This product’s heat-activated bonding creates a covalent-like interface with metal substrates, verified by peel tests exceeding 14N/cm² in the Pro Model. Combined with UV-stable dyes and 5H hardness, it sets a new benchmark for decorative surface engineering in commercial architecture."

Lena Choi - Green Building Advisor

"For projects pursuing LEED or similar certifications, this transfer paper stands out. Its 98% recyclability and RoHS compliance are rare in decorative finishes. I’ve recommended it for three eco-conscious developments where clients wanted wood aesthetics without deforestation or high maintenance."

Posted: 2 days ago

"Applied to brushed aluminum panels—looks like teak. The sublimation process was clean, and the UV resistance is real; no fading after 4 months in a sun-drenched lobby. Will be our go-to for high-end finishes."

Posted: 1 week ago

"Used on curved metal entry doors. Adhesion is rock-solid, and the wood grain wraps smoothly around edges. Exceeded client expectations. Customer support sent free samples before order—very helpful."

Posted: 3 weeks ago

"Advanced Model performs well on steel frames. Only note: ensure surface is perfectly clean before application. Once prepped right, the finish is flawless and durable."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.