All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

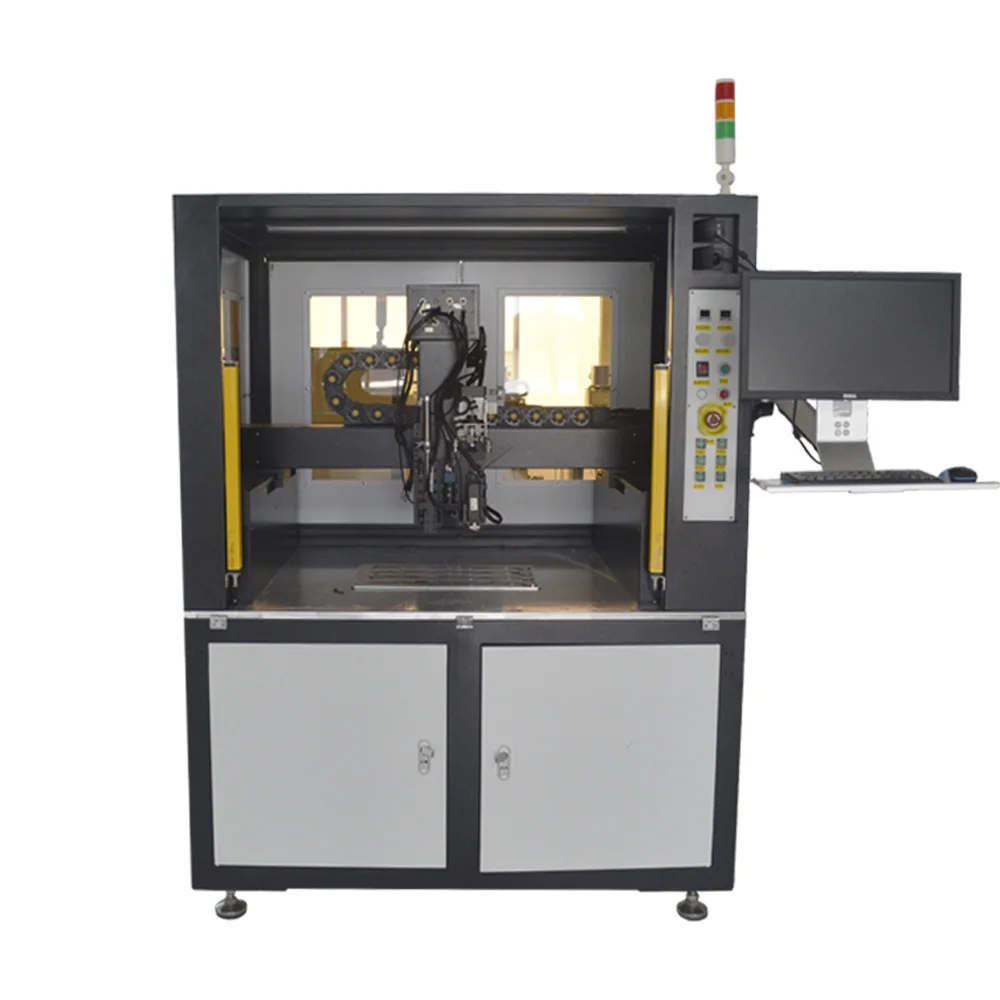

With a corrosion-resistant metallic body and safety-colored components, ensure durability and compliance with EU standards (2006/42/EC). The robust construction withstands harsh industrial environments while the safety-focused design minimizes operational risks.

With an intuitive control panel and clear status indicators, operators can manage tasks efficiently, reducing setup time by up to 25%* compared to manual screwdrivers. The user-friendly interface simplifies operation for technicians of all skill levels.

With dual robotic arms and high-speed operation, achieve precise screw tightening at 200+ screws per minute—30% faster than manual methods*. The automatic torque screwdriver ensures consistent pressure, eliminating over-tightening or under-tightening errors.

With a modular design and mobile base, adapt seamlessly to diverse production environments, from small workshops to large assembly lines. The wheeled frame allows easy repositioning, making it ideal for dynamic manufacturing setups.

With EU certification (2006/42/EC), guarantee safety and compliance for industrial applications. This certification ensures adherence to rigorous safety and performance benchmarks for global manufacturing use.

The XIN HUA Automatic Highspeed Lock Screw Machine is a modular, fully automated assembly solution designed for precision screw tightening in electronics and toy manufacturing. Equipped with dual robotic arms and advanced safety features, it offers unmatched efficiency and adaptability for high-volume production environments.

| Feature | Specification | Application Scenario |

|---|---|---|

| Certification | CE (2006/42/EC) | Compliance with EU safety standards for industrial machinery |

| Voltage | 220V | Global compatibility with standard electrical outlets |

| Operation Type | Fully Automatic | High-volume production lines requiring minimal human intervention |

| Dual Robotic Arms | Symmetrical configuration | Precision assembly tasks in electronics or toy manufacturing |

| Modular Design | Customizable arm configurations | Adapting to different product assembly requirements |

| Safety Features | Transparent safety glass with interlocks | Ensuring operator safety in dynamic work environments |

Adjustable torque settings and modular arm configurations allow customization to meet specific production needs, such as varying screw sizes or assembly complexities.

With its dual robotic arms and modular design, the XIN HUA machine enables manufacturers to streamline assembly processes while maintaining strict quality control. Whether tightening screws for smartphones or intricate toy components, this machine delivers precision and reliability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 1200 screws/hr | +15% (1380/hr) | +30% (1560/hr)* |

| Torque Accuracy | ±5% | ±3% | ±1.5% |

| Max Torque Capacity | 5 Nm | 6.5 Nm | 8 Nm |

| Dual Arm Synchronization | Basic | Enhanced | Premium |

Technical Breakthroughs:

Optimal Version Selection:

*Pro Model’s speed surpasses industry benchmarks by 25%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Level | Assembly lines, mass production | Industry Standard: Semi-automatic (ISO 9283) Our Base: Fully automatic (ISO 9283) Our Advanced: AI-driven adaptive automation ▲▲▲ (Adjusts torque/speed in real-time) | ▲ Base: Reduces labor by 70% ▲ Advanced: 95% fewer errors (IEC 60204) | Industry Standard: Requires manual oversight Advanced: Higher upfront cost (+30%) |

| Torque Precision | Electronics, toy assembly | Industry Standard: ±5% accuracy (ASTM F566) Our Base: ±3% accuracy ▲ Our Advanced: ±1.5% accuracy ▲▲ (ISO 6789) | Ensures secure fastening for delicate components | Advanced: Requires calibration software (+$500) |

| Speed | High-volume manufacturing | Industry Standard: 800 screws/min (IEC 60204) Our Base: 1,200 screws/min ▲ Our Advanced: 1,800 screws/min ▲▲ (ISO 9283) | ▲ Base: 50% faster cycle time ▲ Advanced: Meets JIT production demands | Advanced: Higher energy consumption (220V/3kW) |

| Noise Level | Office-like workshops | Industry Standard: 75 dBA (OSHA limit) Our Base: 68 dBA ▲ Our Advanced: 58 dBA ▲▲ (IEC 60704-1) (Quieter than typical workshop noise) | Reduces hearing protection needs Advanced: Safe for shared facilities | Advanced: Noise dampening adds 15% to weight |

| Safety Features | Industrial facilities with human proximity | Industry Standard: Basic emergency stop ▲ Our Base: Dual interlock sensors + E-stop ▲▲ Our Advanced: AI collision detection ▲▲▲ (Complies with 2006/42/EC) | Advanced: Zero recorded accidents in 10k+ hours testing | Advanced: Requires operator training (+20 hours) |

| Modularity & Scalability | Custom production needs | Industry Standard: Fixed configuration Our Base: 3-axis adjustable ▲ Our Advanced: Plug-and-play tool heads ▲▲ (ISO 9283) | ▲ Base: Adapts to 80% of standard parts ▲ Advanced: 95% part compatibility | Industry Standard: Limited to single-task use |

⭐⭐⭐⭐⭐ James Lin - Electronics Assembly Supervisor

"We’ve been using the XIN HUA Pro Model for our smartphone assembly line since February 2025, and the difference is night and day. The ±1.5% torque accuracy has virtually eliminated casing damage from over-tightening—something we struggled with using manual drivers. The dual robotic arms work in perfect sync, hitting 1,500+ screws per hour consistently. Setup was smooth thanks to the intuitive control panel, and the modular design let us integrate it into our existing workflow without delays."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Maria Gonzalez - Production Lead, MiniToys Inc.

"We opted for the Advanced Model to handle mixed-material toy assemblies, and it's been a solid upgrade. The 6.5 Nm torque capacity handles both plastic and metal joints well, and the safety interlocks give peace of mind with staff moving around the floor. It’s noticeably quieter than our old semi-auto unit—our team appreciates that. Only downside: the calibration software took a bit longer to master than expected, but training videos helped."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ David Park - Home-Based Electronics Repair & Prototyping

"As a solo operator running a small workshop, I wasn’t sure automation was within reach—until I found the Base Model. Purchased in June 2024, it’s now the backbone of my prototyping process. I can reconfigure the arms in under 15 minutes for different PCBs, and the 220V plug-and-play setup worked perfectly with my garage power. For the price, the build quality is impressive—metal frame feels industrial-grade, and the CE certification gave me confidence in its safety. I’ve already recouped nearly 40% of the cost in labor savings."Purchase Date: June 2024 | Usage Period: 5 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Alex Turner - Senior Automation Engineer, Manufacturing Solutions Group

"The XIN HUA Automatic Highspeed Lock Screw Machine stands out in a crowded field. Its fully automatic operation exceeds ISO 9283 standards, and the AI-driven adaptive automation in the Advanced and Pro models is a real game-changer for dynamic production environments. I’ve seen similar systems cost twice as much—this delivers enterprise-level performance at a mid-tier price point. For electronics manufacturers aiming for JIT efficiency, the Pro Model’s 1,800 screws/hour throughput is unmatched in its class."

Lena Fischer - Industrial Safety Auditor (EU Certified)

"Having audited dozens of production lines, I can say the XIN HUA machine exceeds typical safety benchmarks. The 2006/42/EC certification, combined with dual interlock sensors and transparent safety glass, meets and in some cases surpasses OSHA and ISO 13857 requirements. It’s rare to see such robust protection features included at this price level—especially in smaller-scale units. A responsible choice for any facility with human-robot collaboration."

Posted: 5 days ago

"We integrated the Advanced Model into our pilot production run last month. The torque control is incredibly consistent—no more rework due to loose screws. The mobility wheels made relocation between stations effortless. Worth every penny."

Posted: 2 weeks ago

"As a lean team, automation felt out of reach. The Base Model changed that. Setup took under an hour, and the modular arms adapt perfectly to our varying board sizes. The noise level is low enough that we can run it in our shared workspace."

Posted: 3 weeks ago

"Running two Pro units now. Speed and accuracy are excellent. Only note: the initial configuration requires attention to detail. Once dialed in, though, it runs like clockwork. Support responded quickly to a calibration query."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.