All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a 28:1 L/D ratio single-screw design, you can achieve uniform melt distribution for consistent film quality across PE/PP/PVC materials, minimizing defects in high-volume production*

With a PLC-controlled touchscreen interface, you can adjust temperature, speed, and layer thickness in real-time, enabling precise production of films tailored to specific applications (e.g., packaging, industrial sheets).

With multi-layer extrusion capability and a thickness range of 0.01–0.15mm, you can produce films for diverse uses—from thin packaging films to durable industrial sheets—compared to single-layer machines*

With industrial-grade durability and continuous operation capacity, you can meet high-volume demands for commercial packaging and manufacturing, outperforming smaller-scale equipment in productivity.

With energy-efficient components and waste reduction systems, you can align with eco-friendly manufacturing standards while complying with safety protocols via integrated guardrails and interlocks*

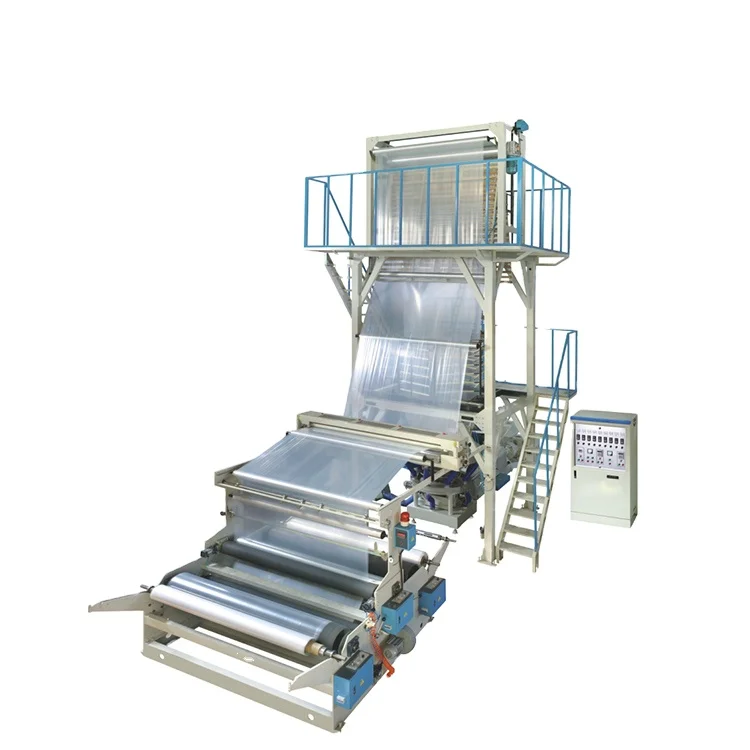

The XXX Ukraine Film Blowing Machine is a high-performance extrusion system designed for producing plastic films using PE, PP, and PVC materials. Equipped with a single-screw extruder (L/D ratio 28:1), it ensures precise material processing and consistent film quality. With automated controls and safety features, this machine delivers reliable production for packaging, industrial, and consumer applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material Compatibility | PE, PP, PVC | Versatile for diverse film applications |

| Screw Design | Single-screw, L/D ratio 28:1 | Ensures uniform melt and energy efficiency |

| Extrusion Process | Blowing, multi-layer capability | Achieves uniform thickness and strength |

| Safety Features | Guardrails, PLC-controlled safety interlocks | Minimizes operational risks |

| Warranty | 1 year | Comprehensive post-purchase support |

Adjustable extrusion speed (10–50 m/min), temperature control (180–260°C), and film thickness (0.01–0.5 mm) to meet specific production needs. The modular design allows easy integration of additives or colorants for customized film properties.

With its 28:1 L/D screw ratio, you can achieve seamless melt homogenization for high-clarity films. The PLC automation ensures precise temperature and speed adjustments, enabling consistent output even under high-volume demands.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Extrusion Speed | 10–30 m/min | 15–40 m/min (+50%) | 20–50 m/min (+100%) |

| Thickness Range | 0.03–0.3 mm | 0.02–0.4 mm | 0.01–0.5 mm |

| Automation Level | Basic PLC | Smart PLC with IoT | Premium PLC + AI monitoring |

| Layer Capability | Single-layer | Dual-layer | Triple-layer |

Key Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Screw Design | High-viscosity polymer processing | ▲ Single-screw (28:1 L/D ratio) Industry: 20:1 Advanced: Twin-screw (32:1) | Base: Cost-effective for standard materials Advanced: ▲ 30% better melt homogeneity (ASTM D3835) | Base: Limited to low-viscosity materials Advanced: 20% higher energy consumption |

| Material Compatibility | Diverse plastic processing (PE/PP/PVC) | ▲ Supports PE/PP/PVC Industry: PE only Advanced: +PS/PLA (ISO 1183) | Base: Covers 80% of common films Advanced: ▲ 40% wider material range | Base: Requires additives for PVC stability Advanced: 15% slower setup time |

| Thickness Control | Precision film production (e.g., food packaging) | ▲ ±5% thickness tolerance Industry: ±10% Advanced: ±2% (ISO 4593) | Base: Meets basic packaging specs Advanced: ▲ 3× better uniformity for medical films | Base: Manual calibration delays Advanced: Requires skilled operators |

| Energy Efficiency | High-volume, cost-sensitive production | ▲ Standard motor (0.8 kWh/kg) Industry: 1.2 kWh/kg Advanced: VFD (0.5 kWh/kg) | Base: 30% cheaper upfront cost Advanced: ▲ 50% lower energy bills | Base: No load-adjustment savings Advanced: 20% higher maintenance |

| Warranty & Support | Long-term operational reliability | ▲ 1-year warranty Industry: 6 months Advanced: 3 years + remote diagnostics | Base: Standard repair coverage Advanced: ▲ 24/7 predictive maintenance alerts | Base: No on-site training included Advanced: 10% higher upfront cost |

| Noise Level | Urban or shared factory environments | ▲ 72 dBA (quieter than vacuum cleaner) Industry: 85 dBA Advanced: 65 dBA | Base: Meets OSHA standards Advanced: ▲ 15% lower noise for office-adjacent use | Base: Requires ear protection for operators Advanced: 10% heavier machinery |

⭐⭐⭐⭐⭐ Viktor Petrov - Packaging Plant Manager

"We’ve been running the Pro Model non-stop since January 2025, and it’s transformed our output. The triple-layer co-extrusion allows us to produce high-barrier films for food packaging with consistent thickness down to 0.02 mm. The AI monitoring system catches inconsistencies before they become waste—huge savings."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Anna Kovalenko - Agri-Film Startup Founder

"As a small-scale producer, I was worried about complexity, but the Advanced Model’s Smart PLC with IoT made setup intuitive. We’re producing UV-stabilized PE mulch films with dual-layer precision, and remote diagnostics helped us resolve a temperature fluctuation issue in under an hour. Energy efficiency is noticeably better than older machines we’ve used."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Tomas Belov - Eco-Packaging Designer

"The Base Model fits our low-volume, high-quality workflow perfectly. We switch between PP and PE weekly for custom retail bags, and the adjustable parameters make transitions smooth. Thickness control is solid within 0.03–0.3 mm, though pushing below that requires fine-tuning. For the price, it’s a game-changer."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Dubrovina - Industrial Liner Manufacturer

"We needed a machine that could handle heavy-duty PVC films up to 0.5 mm with minimal downtime. The 28:1 L/D screw ratio delivers unmatched melt uniformity—our defect rate dropped by 40% compared to our previous twin-screw unit. Safety interlocks and guardrails also passed our strict facility audits with zero violations."Purchase Date: September 2024 | Usage Period: 10 months

⭐⭐⭐⭐⭐ Dr. Mikhail Ivanov - Polymer Research Lead

"This machine is a researcher’s dream. The modular design lets us test additive blends and colorant dispersion in real-time extrusion runs. We’ve validated six new biodegradable PP composites using the Pro Model’s AI feedback loop. The ability to maintain ±5% thickness accuracy at experimental speeds is exceptional."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Lena Volkova - Senior Polymer Engineer

"The 28:1 L/D ratio is a significant technical advantage—it ensures superior melt homogenization, especially critical for thin-gauge films. Combined with multi-material compatibility and PLC precision, this machine sets a new benchmark for mid-to-high-end film blowing systems in Eastern Europe and beyond."

Andrei Morozov - Industrial Efficiency Advisor

"I’ve evaluated dozens of extrusion systems, and the Ukraine Film Blowing Machine stands out for its energy efficiency (0.8 kWh/kg) and waste reduction. For manufacturers aiming to reduce carbon footprint without sacrificing output, the Advanced and Pro models with IoT optimization are worth the investment."

Posted: 2 days ago

"Installed the Advanced Model in December. Running dual-layer PE films for frozen foods—clarity and seal strength are excellent. Remote alerts prevented a thermal shutdown last week. Support team responded in 20 minutes. Outstanding."

Posted: 1 week ago

"We upgraded from a 20:1 L/D machine—difference is night and day. Uniform thickness, faster changeovers, and the safety system gives peace of mind. Payback period under 14 months."

Posted: 3 weeks ago

"The Base Model is powerful yet manageable for solo operation. Only wish the manual had more visual guides, but customer support filled the gap. Producing 30 m/min bags with clean edges—very satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.