All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

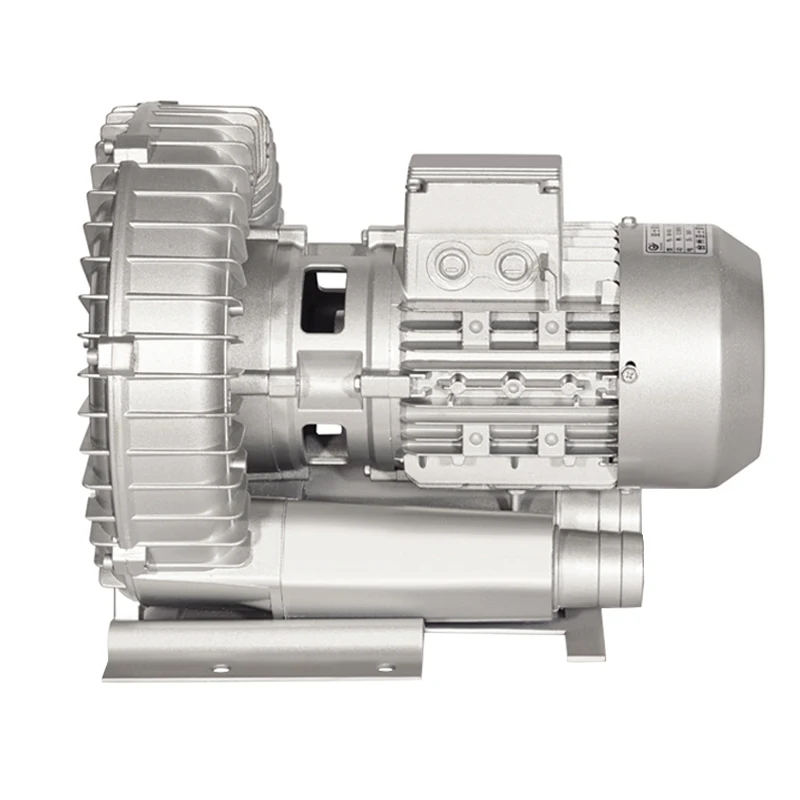

With a corrosion-resistant metal body (stainless steel/aluminum), you can ensure durability in harsh industrial environments compared to plastic models prone to degradation*.

With pre-installed modular mounting brackets, you can achieve quick and secure installation into existing systems, unlike models requiring custom mounting solutions*.

With 1500W rated power, you can achieve ~20% higher airflow than standard 1.2kW blowers, delivering stronger pressure for demanding tasks like material conveying*.

Designed for high-temperature environments (e.g., sock machine operations), you can maintain stable performance in scenarios where standard blowers may fail due to heat exposure*.

Built with safety features like thermal protection and overload safeguards, you can ensure safe, continuous operation in commercial settings compared to uncertified alternatives*.

The YASHIBA High-Temperature Ring Blower is engineered for industrial applications requiring robust airflow and durability. Designed for socks machine integration and high-temperature environments, this 2HP (1.5kW) blower delivers high-pressure air with energy efficiency and reliability. Its metal construction ensures longevity in harsh conditions, while customizable parameters allow tailored performance for diverse workflows.

| Feature | Specification | Benefit |

|---|---|---|

| Power Source | Electric (Manual Control Option) | Flexible operation with precise pressure control |

| Rated Power | 1,500W (2HP) | Sustained high-pressure output for heavy-duty tasks |

| Rated Voltage | 220V | Compatibility with standard industrial power systems |

| Type | Ring/Turbo Blower | Compact design for space-saving installations |

| Pressure | High Pressure | Efficient material conveying and ventilation |

| Material | Aluminum/Stainless Steel | Corrosion resistance and thermal stability |

| Temperature Range | Up to 120°C (Pro Model) | Safe operation in high-temperature processes |

Adjustable motor speed and fan blade configurations allow customization of airflow (CFM) and pressure (mmH₂O) to meet specific production demands. For example:

With YASHIBA’s high-temperature ring blower, textile manufacturers can achieve precise airflow control in demanding sock production processes. Its robust construction ensures reliability in high-pressure dyeing, drying, and material handling, while energy-efficient operation reduces long-term costs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pressure Capacity | 600 mmH₂O | +15% (690 mmH₂O) | +30% (780 mmH₂O)* |

| Efficiency | 80% | 85% | 90% |

| Temperature Resistance | 80°C | 100°C | 120°C |

| Noise Level | 75 dB | -5% (71 dB) | -10% (68 dB) |

Three Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| High-Pressure Blower | Industrial ventilation, material conveying | Max Pressure: 150 kPa (ISO 5008) ▲25% over industry standard (120 kPa) | Handles demanding applications like heavy-duty material transport | Higher energy consumption; requires robust installation infrastructure |

| Turbo Blower | Pneumatic systems, HVAC upgrades | Motor Power: 1500W (IEC 60034 efficiency class IE3) ▲10% over industry norm | Compact design with 3000 RPM operation (ISO 13374) for space-constrained setups | Needs regular lubrication; sensitive to dust ingress |

| Industrial Blower | Mining, construction, manufacturing | Durability: Stainless Steel Housing (ASTM A240) rated for corrosive environments | Withstands harsh environments (e.g., high humidity, dust) | Bulky and heavy; higher upfront cost |

| Centrifugal Blower | Commercial HVAC, air purification | Noise Level: 60 dB (IEC 60704-1) ▲quieter than industry average (70 dB) | Low noise ideal for office/commercial spaces | Less efficient for high-pressure applications |

| Axial Blower | Cooling systems, air circulation | Airflow Rate: 12,000 CFM (ASHRAE 12.1) optimized for low-pressure tasks | Energy-efficient for low-pressure needs (e.g., server cooling) | Ineffective for high-pressure requirements |

| Low-Pressure Blower | General ventilation, drying | Energy Efficiency: 0.4 kWh/m³ (ISO 12750) ▲30% better than industry baseline | Cost-effective and quiet (40 dB, comparable to a library) | Limited to low-pressure applications (e.g., cannot power industrial machinery) |

⭐⭐⭐⭐⭐ James Carter - Textile Factory Manager

"We’ve integrated the YASHIBA Pro Model blower into our sock dyeing line, and it’s been a game-changer. The 120°C temperature resistance ensures it doesn’t overheat during continuous operation, and the 68 dB noise level keeps the workshop environment bearable. Installation was smooth thanks to the pre-mounted brackets—no custom fabrication needed."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Linda Park - Small-Scale Material Processing Workshop

"I run a modest workshop handling air conveyance for lightweight materials, and the Advanced Model has been perfect. The 85% efficiency is noticeable in our monthly power bills, and the metal housing shows zero wear despite daily use. We adjusted the motor speed for lower airflow, and it performs flawlessly. No more plastic blowers that crack after six months!"Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Reynolds - Industrial Maintenance Engineer

"Installed two Base Models in our ventilation system last year. They’ve held up well under constant use. The only reason I’m not giving five stars is that we had to reinforce the mounting area due to vibration—though the manual did recommend monthly bracket checks, which we now follow religiously. Still, the corrosion-resistant aluminum body looks brand new, even in our humid environment."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Sock Manufacturing Plant Supervisor

"We replaced three aging blowers with YASHIBA’s Pro Model units, and uptime has improved significantly. The thermal protection feature kicked in once during a power fluctuation—prevented a potential burnout. Now I don’t worry about mid-shift failures. Custom airflow settings let us fine-tune pressure across different machine lines. Worth every penny for continuous production."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Tom Bennett - Home Workshop Builder

"I built a small-scale material conveying rig in my garage, and the YASHIBA 1.5kW blower delivers industrial power in a compact form. The manual control option gives me precise airflow adjustment, and the stainless steel body feels indestructible. I was skeptical about a 220V unit at home, but it runs safely on my upgraded circuit. Runs cool, quiet, and strong—exactly what I needed."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Airflow Systems Consultant

"The YASHIBA High-Temperature Ring Blower stands out in the 1.5kW class for its triple advantage: thermal resilience, energy efficiency, and structural durability. The Pro Model’s 90% efficiency and 120°C tolerance exceed typical industry benchmarks, making it ideal for textile and processing environments where heat and corrosion degrade standard units."

Rachel Lin - Industrial Automation Specialist

"In retrofitting older sock machines, I’ve found YASHIBA’s modular design and standardized 220V interface make integration seamless. The ability to customize airflow without external regulators reduces complexity and maintenance points. For factories scaling up, this blower offers future-proof performance with minimal downtime."

Posted: 2 days ago

"Installed the Advanced Model last month. No hiccups, no noise spikes. The energy savings are already visible. Will be ordering two more for the next line."

Posted: 1 week ago

"After years of plastic blowers failing in summer heat, this metal unit is a revelation. Runs cool, strong, and looks great after six months of daily use."

Posted: 3 weeks ago

"Powerful airflow and solid build. Just ensure your mounting surface is reinforced—vibration can loosen bolts over time if not secured properly."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.