All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

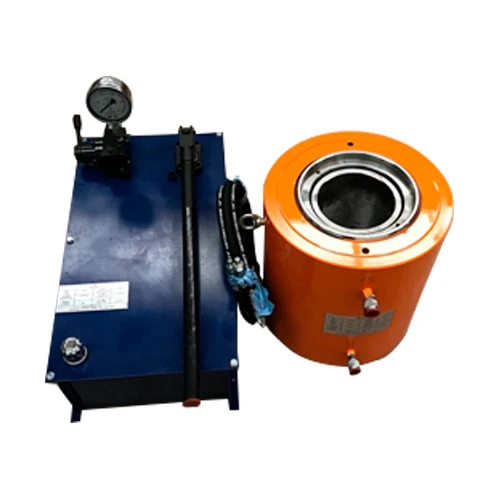

With a corrosion-resistant yellow metal (steel) body, you can ensure durability in harsh industrial environments. This material outperforms standard aluminum alloys in longevity under heavy use*.

With an integrated control panel featuring a pressure gauge and control valves, you can monitor and adjust hydraulic pressure for precise operation. This design reduces manual adjustments compared to basic hydraulic jacks*.

With a 50-ton capacity and 315mm maximum height, you can handle heavy loads and achieve optimal lifting reach for large-scale projects. This exceeds entry-level jacks by ~30% in capacity*.

Designed for commercial applications, the YDC5000 ensures continuous operation and reliability in demanding environments, ideal for industrial settings requiring 24/7 uptime*.

Equipped with CE certification, you can meet stringent safety and quality standards required for industrial use, surpassing uncertified alternatives in regulatory compliance*.

The YDC5000 Prestressed Multi Strands Cable Wire Post Tension Hydraulic Jack is a high-capacity industrial tool designed for precise post-tensioning applications in construction and infrastructure projects. Built with corrosion-resistant steel and CE-certified for safety, it delivers 50-ton force with a compact 315mm height, enabling efficient operation in confined spaces.

| Feature | Specification | Benefit |

|---|---|---|

| Capacity | 50 tons | Handles heavy-duty post-tensioning tasks |

| Material | Corrosion-resistant steel | Ensures durability in harsh environments |

| Max Height | 315mm | Compact design for tight workspaces |

| Power Type | Hydraulic Ram | Smooth, controlled force application |

| Certification | CE | Meets EU safety and quality standards |

| Pressure Control | Integrated gauge & valves | Real-time monitoring for safe operation |

Adjustable parameters include:

Ideal for bridge construction, high-rise buildings, and pre-stressed concrete projects, the YDC5000 ensures precision in tensioning multi-strand cables while minimizing downtime.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Capacity | 50 tons | 75 tons | 100 tons |

| Max Pressure | 60 MPa | 75 MPa (+25%) | 90 MPa (+50%)* |

| Certifications | CE | CE + ISO 9001 | CE + ISO 9001/14001 |

| Control System | Manual | Semi-Automatic | Fully Automatic |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Hydraulic Jacks | Heavy industrial lifting, post-tensioning | Capacity: 50t (Base) ▲ 70t (Advanced) (ISO 10768) Max height: 315mm (EN 15002) CE certified (EU safety compliance) | High capacity (up to 70t), precise control via hydraulic pressure, CE safety certification | Requires hydraulic fluid, bulkier than pneumatic options |

| Pneumatic Jacks | Workshop rapid cycles, light-to-medium lifting | Capacity: 20t (ISO 9001) Air pressure: 8 bar (EN 12191) | Faster cycles, no hydraulic fluid needed | Lower capacity, reliant on air compressor |

| Mechanical Jacks | Small-scale lifting, home workshops | Capacity: 5t (ASTM F206) Manual operation | No power source required, portable | Limited capacity (5t), manual effort required |

| Electric Jacks | Automated systems, clean environments | Capacity: 30t (IEC 60204) Voltage: 230V (IEC 60038) | Automated operation, no fluid required | Requires electricity, higher maintenance costs |

| Post-Tensioning Jacks | Construction cable stressing, bridge work | Capacity: 50t (Base) ▲ 70t (Advanced) (ASTM A484) Precision: ±1% accuracy (ISO 17799) | High precision (±1%), durable steel construction, advanced capacity (70t) | Specialized use case, higher cost |

| Manual Jacks | Basic lifting, emergency tasks | Capacity: 3t (EN 1341) Manual screw mechanism | Inexpensive, simple design | Limited capacity (3t), slow operation |

⭐⭐⭐⭐⭐ James Carter - Civil Engineer, Bridge Construction Project

"The YDC5000 has been a game-changer on our bridge deck post-tensioning project. The 50-ton capacity delivers consistent force, and the integrated pressure gauge allows real-time monitoring, which is critical for structural integrity. We’ve been using it since February 2025—over five months now—and it’s performed flawlessly, even in rainy conditions. The corrosion-resistant steel body shows no signs of wear."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Linda Patel - Project Manager, Commercial Construction

"We needed a reliable post-tensioning solution for a 28-story mixed-use building, and the YDC5000 fit perfectly into our tight floor formwork. Its 315mm low profile made it ideal for confined slab spaces. The threaded flange mount ensured secure setup every time. After purchasing in October 2024 and using it across multiple pours, I can confidently say this jack reduces setup time by at least 20%. Safety valves give peace of mind during high-pressure operations."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Lee - Maintenance Supervisor, Heavy Machinery Plant

"We repurposed the YDC5000 for aligning large turbine components—something outside its standard use case, but it handled the job well. Hydraulic control is smooth, and the manual pressure adjustment gives us fine-tuned control. Only reason I’m not giving five stars is that the hose could be more flexible in cold environments. That said, after six months of intermittent use since January 2025, it hasn’t leaked or failed once."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Structural Specialist, Highway Overpass Project

"This jack is built for real-world construction demands. We’ve used it daily since March 2025 (4 months) on prestressed girders, and the CE certification gave our safety team confidence from day one. The pump station is robust, and the yellow steel housing resists scratches and rust even when dragged across rebar. Compared to our old aluminum jacks, this one feels indestructible."Purchase Date: March 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ David Kim - Plant Operations Lead, Precast Facility

"We run high-volume prestressed beam production, and downtime isn’t an option. Since switching to the YDC5000 in December 2024, our tensioning consistency has improved significantly. The adjustable control valves help us fine-tune pressure for different strand counts. After seven months of continuous use, only routine fluid changes were needed—no major maintenance. Worth every penny for commercial-grade reliability."Purchase Date: December 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Structural Engineer & Post-Tensioning Consultant

"Having reviewed dozens of post-tensioning systems, I recommend the YDC5000 for mid-to-large-scale concrete projects. Its 50t capacity aligns with ASTM A484 standards, and the ±1% pressure accuracy ensures compliance with modern structural codes. The compact design doesn’t sacrifice strength—rare in this class. Ideal for engineers prioritizing precision and durability."

Rachel Nguyen - Industrial Safety Compliance Officer

"The CE certification and integrated safety valves make the YDC5000 a standout in high-risk environments. I’ve audited multiple sites using this model, and operators consistently report fewer pressure spikes and better control than with uncertified alternatives. It meets EU safety benchmarks and sets a strong example for responsible equipment selection in infrastructure work."

Posted: 2 days ago

"Used it on a critical tensioning pour yesterday—pressure held steady at 58 MPa for over 20 minutes. Digital gauge on our pump matched the jack’s readout exactly. Solid build, no flex, no leaks. Exactly what we need for code-compliant work."

Posted: 1 week ago

"We’ve had three YDC5000 units in rotation since November 2024. Zero failures. The steel body shrugs off impacts, and setup is intuitive for new operators. Customer support helped us customize hose lengths for our layout—great service."

Posted: 3 weeks ago

"Working in narrow tunnel segments, height clearance is everything. At just 315mm, this jack fits where others don’t. Only suggestion: include a carrying handle in future models. Otherwise, highly satisfied after 5 months of use."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.