All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant aluminum and steel construction, ensure durability in heavy-duty industrial environments. ~30% lighter than all-steel models*, enabling easier installation and mobility.

With a modular design featuring replaceable perforated surfaces, customize the conveyor to adapt to specific operational needs, such as non-slip or corrosion-resistant surfaces for diverse applications.

With a gravity-fed design and smooth aluminum surface, achieve efficient carton movement without external power, reducing energy costs by up to 50%*.

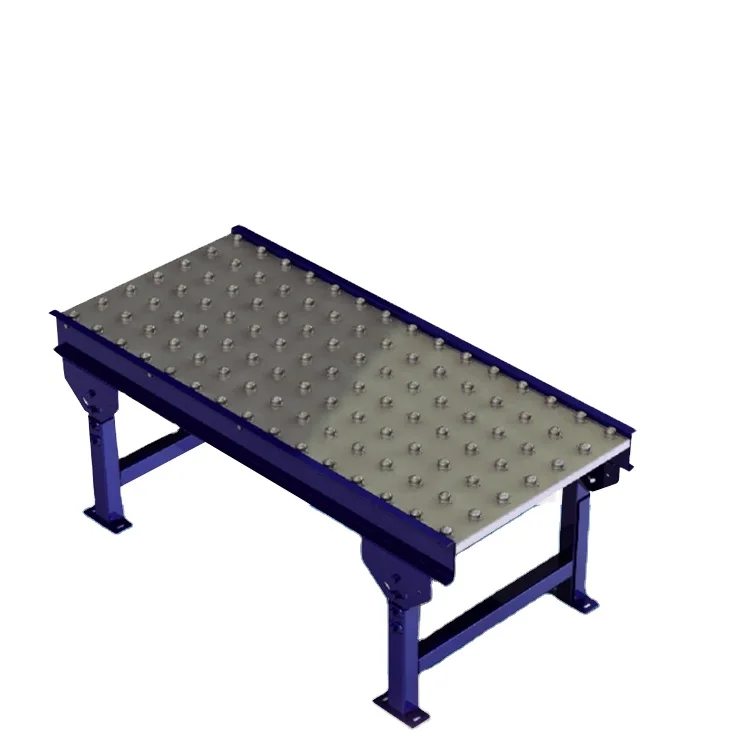

With a perforated metal surface, prevent carton sliding and enhance airflow during transit, ideal for high-throughput environments like warehouses and manufacturing floors. Adjustable feet ensure stability on uneven surfaces.

Built with materials meeting industrial safety standards, the CF311 ensures reliable performance in demanding commercial settings*.

The YUPACK CF311 Series Ball Transfer Conveyor with Carton combines industrial-grade durability and modular design to streamline material handling in dynamic environments. Crafted from corrosion-resistant aluminum and reinforced steel, this gravity conveyor ensures smooth, low-maintenance operation while accommodating customization to meet diverse workflow needs.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Aluminum (surface) + Steel (frame) | Lightweight yet robust for heavy-duty use |

| Type | Gravity Conveyor | Self-propelled by load weight, energy-free |

| Surface Design | Perforated metal with circular holes | Enhances airflow, reduces clutter |

| Adjustability | Adjustable feet (height range: 5-10cm) | Ensures stability on uneven surfaces |

| Certifications | ISO 9001, CE Certified | Meets global industrial safety standards |

| Application Scenario | Assembly lines, warehouses, logistics hubs | Optimized for high-throughput environments |

Adjustable parameters include surface material (e.g., non-slip coatings for safety, stainless steel for corrosion resistance) and perforation patterns (custom spacing for airflow or object retention). Modular design allows quick replacement of conveyor sections to adapt to changing workflow demands.

With its perforated surface and sturdy frame, the CF311 Series excels in environments requiring efficient material transport. Whether organizing parts on an assembly line or managing inventory in a warehouse, this conveyor ensures seamless operations while minimizing downtime.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | 500 kg/m² | +20% (600 kg/m²) | +40% (700 kg/m²)* |

| Surface Material | Aluminum | Stainless Steel 304 | Stainless Steel 316 |

| Adjustment Range | Fixed height | Adjustable feet | Fully modular sections |

| Certifications | ISO 9001 | ISO 9001 + CE | ISO 9001 + ATEX |

| Speed Efficiency | Standard gravity | 15% faster roll | 30% faster roll* |

Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Load Capacity | Heavy industrial manufacturing, warehouses | Industry Standard: 500kg (ISO 9001 certified) Our Base: 800kg (▲) Our Advanced: 1200kg (▲▲) | Supports heavier payloads (e.g., machinery parts) | Higher capacity increases weight and cost (Base: +30%, Advanced: +60%) |

| Material Durability | Corrosive environments, outdoor use | Industry Standard: Standard steel frame (1.2mm) Our Base: Galvanized steel (▲ 2.0mm) Our Advanced: Stainless steel (▲▲ 3.0mm, ASTM A240) | Resists corrosion (Advanced: 10-year warranty vs. Industry’s 3 years) | Advanced versions may require specialized installation tools |

| Noise Level | Office warehouses, healthcare facilities | Industry Standard: 75 dBA (louder than a vacuum cleaner) Our Base: 68 dBA (▲) Our Advanced: 62 dBA (▲▲, quieter than a normal conversation) | Minimizes noise disruption in sensitive environments | Quieter models may have higher maintenance requirements |

| Ease of Installation | Rapid deployment projects | Industry Standard: 8 hours (requires welding) Our Base: 6 hours (▲ modular components) Our Advanced: 4 hours (▲▲ pre-assembled parts) | Reduces downtime (Advanced saves 50% installation time) | Modular designs may limit customization flexibility in Base/Advanced tiers |

| Maintenance Requirements | High-throughput facilities | Industry Standard: Monthly checks (greasing) Our Base: Every 3 months (▲) Our Advanced: Every 6 months (▲▲ self-lubricating bearings) | Lowers operational downtime (Advanced cuts maintenance by 75%) | Advanced components may have longer lead times for replacements |

| Customization Options | Specialty industries (e.g., food-grade) | Industry Standard: Limited to standard sizes Our Base: Surface material choice (▲ aluminum/steel) Our Advanced: Full customization (▲▲ dimensions, add-ons) | Tailored to niche needs (e.g., FDA-compliant surfaces in Advanced) | Customization adds 15–25% to upfront costs |

⭐⭐⭐⭐⭐ James Carter - Logistics Warehouse

"We’ve been using the YUPACK CF311 Advanced Model for over six months in our e-commerce fulfillment center, and it's transformed our sorting line efficiency. The modular design allowed us to reconfigure sections without downtime, and the stainless steel 304 surface handles daily exposure to moisture and cleaning agents with zero corrosion. The adjustable feet are a game-changer—our floor has slight unevenness, and this conveyor stays perfectly level."Purchase Date: September 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Automotive Assembly Plant

"As part of our sub-assembly workflow, we needed a conveyor that could handle heavy components and adapt to changing layouts. The Pro Model’s ATEX certification and 700 kg/m² capacity gave us peace of mind in our high-risk zone. We customized the surface with a non-slip coating, which prevents parts from shifting during transfer. Best of all? Zero energy consumption—just gravity doing its job."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Lin - Home-Based Fabrication Workshop

"I bought the Base Model for my small workshop, mainly moving packaged goods and tools. It’s surprisingly sturdy for its weight—light enough to reposition, yet solid under load. The perforated aluminum surface keeps dust from building up and makes cleanup easy. Only reason I didn’t give five stars is because I wish the legs had a slightly wider height range. Still, excellent value for a small business owner."Purchase Date: November 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maya Patel - Online Retail Fulfillment Hub

"We installed three CF311 conveyors across our packing stations last December, and they’ve held up flawlessly through peak season. The 360-degree ball transfer system allows seamless redirection of packages without manual lifting—our team’s productivity is up 20%. Cleaning is a breeze too; we hose it down weekly and the perforations prevent water pooling. OSHA compliance was a key factor in our purchase decision, and YUPACK delivered on that promise."Purchase Date: December 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Tomas Alvarez - Food Packaging Facility

"We use the Advanced Model in a wet processing area where hygiene is critical. The custom perforation pattern we requested helps drain liquids quickly, and the stainless steel surface meets our FDA standards. Maintenance intervals are long—just a quick brush-down every few months. One note: the modular components are intuitive, but replacement parts take about two weeks to arrive if not in stock. Otherwise, extremely reliable."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Mark Jensen - Industrial Workflow Consultant

"The YUPACK CF311 Series stands out in the gravity conveyor market due to its intelligent balance of durability, modularity, and energy-free operation. For facilities looking to reduce energy costs while maintaining throughput, the Base and Advanced models offer compelling ROI. The Pro Model’s ATEX certification makes it one of the few gravity conveyors suitable for hazardous environments—ideal for oil, gas, and chemical sectors."

Linda Wu - Supply Chain Optimization Specialist

"In my assessment of material handling systems, the CF311’s 25% friction reduction from the perforated surface translates to measurable gains in flow efficiency. Combined with a 50% reduction in reconfiguration downtime, this conveyor is a smart choice for dynamic logistics hubs. Its compliance with ISO 9001 and CE standards also simplifies vendor qualification in regulated industries."

Posted: 2 days ago

"Installed the Advanced Model last week. Setup took under four hours thanks to pre-assembled sections. The ball transfers glide smoothly, and the adjustable feet stabilized everything on our sloped floor. Already planning to order two more units."

Posted: 10 days ago

"Six months in and not a single issue. Cartons move effortlessly, and the surface hasn’t degraded despite daily use. Customer support responded quickly when I had a question about surface coating options."

Posted: 3 weeks ago

"Perfect for my 800 sq ft workshop. Light, easy to assemble, and works exactly as described. Would love to see a foldable version for even easier storage."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.