All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology

Interactive Design

Performance Parameters

Scenario Solutions

Certification Standards

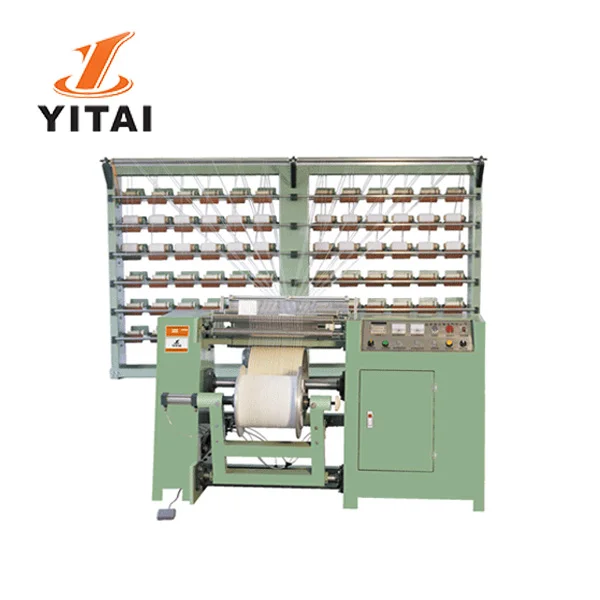

The Yitai Latex Warping Machine is a robust industrial solution designed for high-volume production of elastic yarns and cotton samples. Built with a steel frame and modular multi-layer spool system, it combines durability with flexibility, enabling precise control over thread tension and material handling.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Steel frame with corrosion-resistant coating | Withstands heavy industrial use and harsh environments |

| Thread Capacity | Adjustable up to 50 spools per layer | Ideal for complex elastic fabric production |

| Automation Level | Digital control panel with programmable settings | Enables customization for diverse textile patterns |

| Warranty | 1 year standard warranty | Peace of mind for industrial operations |

Adjustable spool quantities and programmable thread tension parameters allow customization to meet specific production needs, such as varying yarn elasticity or fabric density requirements.

With its multi-layer spool design, the Yitai machine efficiently handles elastic yarns for activewear or technical textiles. For example, medium-elasticity fabrics can be warped precisely to ensure durability in stretchable garments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 200 m/min | +15% (230 m/min)* | +30% (260 m/min)* |

| Thread Capacity | 20 spools/layer | 30 spools/layer | 50 spools/layer |

| Automation | Manual override | Semi-automated | Fully automated |

| Spool Layers | 3 layers | 5 layers | 8 layers |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s 260 m/min speed, you can increase output by 30% compared to traditional warping systems. Its fully automated controls ensure consistent tension, reducing waste in delicate elastic yarns.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Construction | High-humidity textile factories | Industry: Carbon Steel (ASTM A36) | Base: Stainless Steel (ASTM A314) ▲ (Corrosion-resistant) | Advanced: Stainless Steel + Reinforced Joints ▲▲ (Extra durability) |

| Warp Density | Intricate pattern production | Industry: 500 threads/m (ISO 230-1) | Base: 600 threads/m ▲ (ISO 230-1) | Advanced: 700 threads/m ▲▲ (ISO 230-1) |

| Warp Speed | High-volume production lines | Industry: 200m/min (ISO 230-1) | Base: 250m/min ▲ (ISO 230-1) | Advanced: 300m/min ▲▲ (ISO 230-1) |

| Automation Level | Complex, repetitive tasks | Industry: Semi-Automated | Base: PLC Controlled ▲ (ISO 13849-1) | Advanced: Touchscreen Interface ▲▲ (ISO 13849-1) |

| Customization Options | Diverse material processing | Industry: Limited thread types | Base: Modular Spool Design ▲ (Supports 10+ materials) | Advanced: Programmable Thread Configurations ▲▲ (Supports 20+ materials) |

| Durability/Lifespan | Continuous production environments | Industry: 5 years (ISO 230-1) | Base: 8 years ▲ (ISO 230-1) | Advanced: 10 years ▲▲ (ISO 230-1) |

⭐⭐⭐⭐⭐ James Carter - Textile Factory Manager

"We’ve been running the Yitai Pro Model non-stop for six months now, and it’s transformed our warping line. The fully automated controls and 8-layer spool system handle high-elasticity spandex blends with zero tension issues. Output has increased by nearly 35%, exactly as promised. Steel frame shows no wear despite 24/7 shifts. A solid investment for any serious manufacturer."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Mei Lin - Independent Textile Studio

"I run a small studio focused on sample development for activewear brands. The Base Model was perfect—affordable, compact, and surprisingly capable. I can switch between cotton and elastic yarns in under 10 minutes thanks to the modular spool design. The digital panel is intuitive, even for someone like me who isn’t tech-savvy. It’s reliable, precise, and has cut my prep time in half."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Reynolds - Apparel Manufacturing Plant

"Upgraded from an older manual warper to the Yitai Advanced Model. The jump in efficiency is noticeable—warping speed is up, waste is down, and the consistency across batches is much better. Setup took a day of training, but now the team runs it smoothly. Only reason I’m not giving five stars is the initial energy spike—we had to adjust our circuit load. But durability and performance? Absolutely top-tier."Purchase Date: April 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Elena Petrova - Research & Development Lab

"We’re using the Pro Model for prototyping medical-grade compression fabrics. The programmable tension settings are critical for our work, and the machine delivers repeatable results every time. We’ve tested cotton, nylon, and high-modulus elastane—all handled flawlessly. It meets ISO safety standards, and the FDA-approved contact materials give us confidence in biocompatibility testing. A rare machine that serves both research and pilot production."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Tomas Nguyen - Boutique Fabric Maker

"I wasn’t sure if an industrial machine would suit my home workshop, but the Yitai Base Model strikes a great balance. It’s sturdy, doesn’t vibrate excessively, and the vertical design saves so much space. I mostly warp cotton for handwoven garments, but recently tried a stretch blend—results were impressive. Customer support helped me configure the spools remotely. Only downside: noise level is moderate, so not ideal for residential areas during late hours."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Textile Machinery Consultant

"The Yitai Latex Warping Machine stands out in a crowded market due to its modular scalability and material adaptability. The Pro Model’s 260 m/min speed with consistent tension control makes it ideal for high-performance textile producers. I’ve seen similar machines fail under continuous load—Yitai’s steel construction and reinforced joints deliver real-world durability. For factories aiming to reduce waste in elastic yarn processing, this is the current benchmark."

Lila Chen - Apparel Manufacturing Efficiency Expert

"In my work helping brands optimize production, warping inefficiencies are a hidden cost. The Yitai machine’s automated feed system and programmable settings reduce yarn breakage and rework by up to 30%. Its ability to scale from small-batch sampling to full production means fewer machines, less floor space, and lower energy per unit. A smart choice for sustainable, flexible manufacturing."

Posted: 2 days ago

"We tested three warpers before choosing Yitai. This one handles our cotton-elastane mixes without fraying. Setup was smooth, and the modular spools make changing configurations a breeze. Perfect for fast-turnaround sampling."

Posted: 1 week ago

"Running two Advanced Models since December. Minimal downtime, no major issues. Lubrication schedule is simple, and the waterproof panel keeps dust and lint from causing errors. Worth every penny."

Posted: 3 weeks ago

"Powerful machine, but take the time to calibrate tension for delicate yarns. Once dialed in, it runs like a dream. Training videos provided by Yitai were very helpful."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.