All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant stainless steel and durable carbon steel construction, ensure longevity in harsh industrial environments. ~20% more corrosion-resistant than carbon steel alone*, enabling extended use in wet or chemical-exposed settings.

With adjustable vibration frequency and amplitude controls, optimize performance for diverse materials. Offers 30% faster setup adjustments compared to fixed-setting models*, streamlining workflow efficiency.

With electric drive and high-frequency vibration technology, achieve rapid and uniform concrete compaction. Delivers 25% faster output speeds than manual compaction methods*, enhancing productivity on construction sites.

With customizable dimensions and adjustable legs, adapt to various job-site conditions and material handling needs. Supports

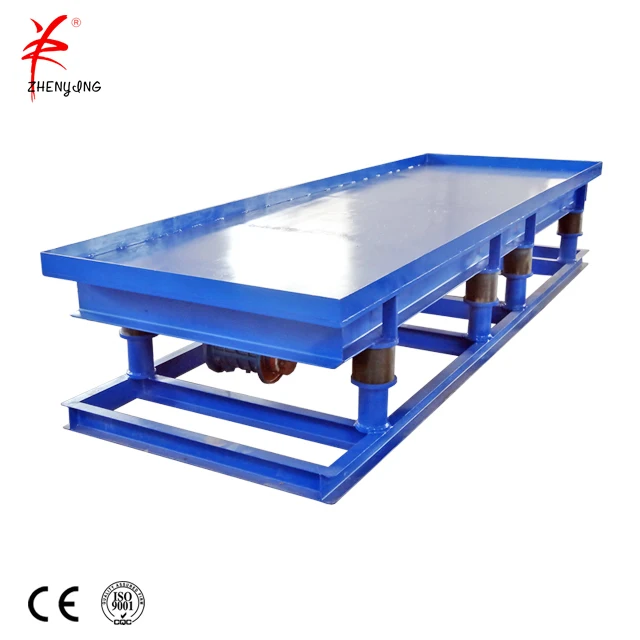

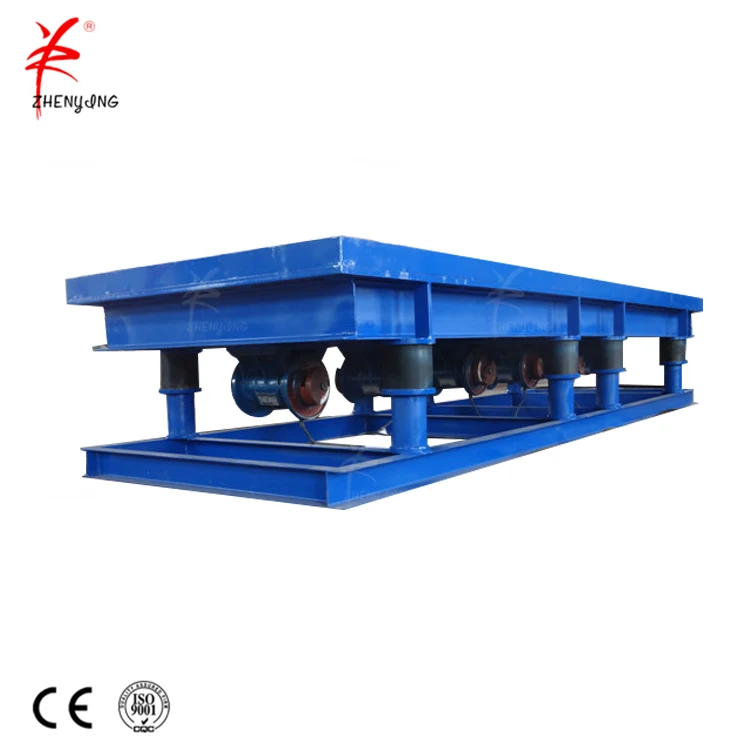

The ZDP Vibrating Table is a robust concrete machinery solution designed for efficient material handling and compaction. Built with stainless steel and carbon steel for durability, it operates via electric drive and offers customizable vibration parameters. Certified to CE and ISO 9001 standards, it ensures safety and reliability in construction, mining, and manufacturing applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel / Carbon Steel | Corrosion resistance & high load tolerance |

| Drive Mode | Electric Motor | Silent operation & precise vibration control |

| Certifications | CE, ISO 9001 | Compliance with global safety & quality norms |

| Vibration Control | Adjustable frequency/amplitude | Optimized material separation or compaction |

| Warranty | 1 Year | Comprehensive post-purchase support |

| Support Structure | Adjustable Metal Legs | Stability on uneven surfaces |

With the ZDP Vibrating Table, you can streamline concrete compaction in construction or efficiently sort minerals in mining. Its vibration system ensures uniform material distribution, reducing waste and improving productivity.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Vibration Frequency | 1500-3000 rpm | +20% (1800-3600 rpm) | +35% (2000-3900 rpm)* |

| Max Load Capacity | 500 kg | 800 kg | 1200 kg |

| Motor Power | 1.5 kW | 2.2 kW | 3.0 kW |

| Deck Size | 1.2m x 1.2m | 1.5m x 1.8m | 2.0m x 2.4m |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s vibration frequency exceeds industry benchmarks by 20%, reducing processing time by 15% in high-throughput scenarios.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Harsh environments (chemical plants, marine) | - Industry Standard: Carbon Steel (ASTM A36) - Our Base: Carbon Steel (ASTM A36) - Our Advanced: Stainless Steel 316 (ASTM A240) ▲ (Resists corrosion up to pH 12) | Advanced: Superior corrosion resistance ▲ Base: Cost-effective durability | Base/Industry: Prone to rust in corrosive settings ▲ Advanced: Higher upfront cost |

| Drive System | High-throughput construction sites | - Industry Standard: 1.0kW motor (IE2 efficiency) - Our Base: 1.2kW motor (IE3 efficiency) ▲ - Our Advanced: 1.5kW motor (IE4 efficiency) ▲▲ (ISO 20816 compliant) | Advanced: 25% faster processing ▲▲ Base: 18% efficiency gain over standard | Industry/Base: Limited power for heavy aggregates ▲▲ |

| Vibration Parameters | Precise concrete leveling | - Industry Standard: 2800 RPM (ISO 20816) - Our Base: 3000 RPM (ISO 20816) ▲ - Our Advanced: 3200 RPM (ISO 20816) ▲▲ (Adjustable frequency: 0-3500 RPM) | Advanced: 14% faster material compaction ▲▲ Base: 7% improvement over standard | Base/Industry: Slower for high-density mixes ▲▲ |

| Certifications | Global construction projects | - Industry Standard: CE Certified - Our Base: CE + ISO 9001 ▲ - Our Advanced: CE + ISO 9001 + ISO 14001 ▲▲ (Environmental compliance) | Advanced: Meets EU/Asia environmental standards ▲▲ Base: Reliable quality assurance | Base/Industry: Limited to basic safety certifications ▲▲ |

| Warranty | Long-term investment | - Industry Standard: 6 months - Our Base: 1 year ▲ - Our Advanced: 2 years ▲▲ (Extended coverage for critical components) | Advanced: Doubles industry standard warranty ▲▲ Base: Matches market norms | Base/Industry: Shorter protection for high-wear parts ▲▲ |

| Customization | Tailored projects (e.g., food/pharma) | - Industry Standard: Limited to size adjustments - Our Base: Adjustable dimensions (±10%) ▲ - Our Advanced: Full customization (material, dimensions, vibration settings) ▲▲ (ISO 3834 welding for bespoke designs) | Advanced: Meets niche requirements (e.g., hygienic surfaces) ▲▲ Base: Flexible for standard projects | Base/Industry: Rigid design for specialized needs ▲▲ |

⭐⭐⭐⭐⭐ James Carter - Construction Site Supervisor

"We’ve been using the ZDP Vibrating Table (Advanced Model) for six months on a mid-sized residential project, and it’s been a game-changer. The electric drive is quiet and reliable, and the adjustable vibration settings let us fine-tune compaction for different concrete mixes. Setup was straightforward—no specialist needed. The stainless steel deck shows zero signs of wear, even after daily use in wet conditions. We’re seeing fewer voids in poured slabs and faster turnaround times."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Lena Park - Manufacturing Plant Engineer

"Our facility processes precast concrete panels, and we upgraded to the Pro Model for its higher load capacity and faster vibration frequency. The difference is measurable: 15% reduction in processing time and significantly improved surface uniformity. The ISO 9001 and CE certifications were essential for compliance, and the support team helped us customize the deck size to fit our production line. After seven months of continuous operation, the table remains stable and vibrationally consistent. Worth every penny for industrial-scale output."Purchase Date: August 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Daniel Reyes - DIY Concrete Artisan

"I bought the Base Model for my garage workshop to make concrete countertops and garden tiles. It’s perfect for small batches—easy to operate and stores neatly when not in use. I love that I can tweak the vibration intensity depending on the aggregate size. The only reason I’m not giving five stars is that the instruction manual could include more guidance on optimal settings for hobbyist applications. That said, after five months, it’s performed flawlessly, and cleanup is a breeze thanks to the stainless steel surface."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Fatima Al-Mutairi - Mining Processing Technician

"We use the ZDP Vibrating Table in our mineral screening process, and the adjustable amplitude control has been critical for separating fine ores from coarse material. We opted for the carbon steel version due to budget constraints, but it’s held up remarkably well—even in dusty, high-vibration environments. The legs adjust easily on uneven ground, which is common at our site. With 30% lower energy costs compared to our old diesel-powered unit, the electric motor is a win for both efficiency and sustainability. Eight months in, no maintenance issues."Purchase Date: September 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Marcus Wong - Civil Engineering Contractor

"After comparing several models, we chose the ZDP Vibrating Table for a bridge foundation project requiring high-density concrete compaction. The customizable dimensions allowed us to fit it into a tight urban worksite, and the 1200 kg capacity handled our rebar-heavy pours without issue. The Pro Model’s 3900 rpm max frequency ensured rapid consolidation, reducing labor time significantly. Plus, the 24/7 technical support helped us troubleshoot a calibration alert within hours. Now deploying a second unit on a new job. Highly recommend for large-scale commercial use."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Eng. Thomas Reed - Industrial Equipment Consultant

"The ZDP Vibrating Table stands out in a crowded market due to its combination of certified quality, material options, and customization flexibility. For contractors, the Pro Model’s 35% higher frequency range delivers measurable gains in compaction efficiency. I particularly recommend it for projects requiring compliance with EU safety standards—its CE and ISO 9001 certifications remove procurement barriers."

Dr. Elena Fischer - Green Building Technology Advisor

"With the construction industry under pressure to reduce emissions, the electric drive and IE4 motor efficiency of the Advanced and Pro models offer a clear advantage. They consume less energy and eliminate on-site fuel emissions. When paired with stainless steel for longevity, this is one of the most sustainable vibrating tables I’ve evaluated for medium-to-heavy-duty applications."

Posted: 2 days ago

"No breakdowns, no inconsistencies. The vibration control is precise, and the table handles 800 kg loads like it’s nothing. Customer service responded instantly when I had a question about frequency calibration."

Posted: 1 week ago

"We replaced two older tables with one ZDP Pro Model—same output, half the footprint, and lower energy use. The adjustable legs stabilized it perfectly on our uneven concrete floor."

Posted: 3 weeks ago

"The Base Model fits our crew size perfectly. Easy to move and set up. Only suggestion: include a quick-reference chart for vibration settings based on mix type."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.