All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

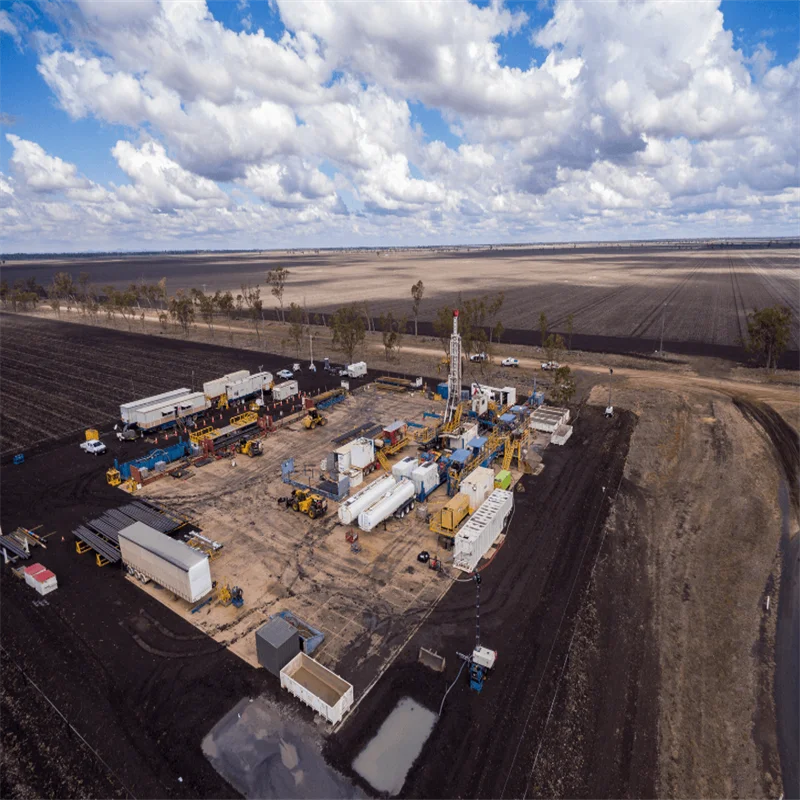

With corrosion-resistant HDPE and ultra-durable UHMWPE, protect drilling sites from heavy equipment wear while outperforming traditional wood or metal mats*. The rigid plastic construction ensures long-term use in harsh environments.

With a modular panel design, quickly assemble custom pathways to accommodate drilling rig movements and equipment layouts. Easy-to-connect panels adapt to uneven terrain, streamlining setup compared to fixed or non-modular alternatives*.

With rigid hardness engineered to withstand loads exceeding 10 tons per panel, safely support drilling rigs and heavy trucks without deformation. Outperforms conventional plastic sheets in load distribution and durability*.

For drilling operations, reduce environmental impact with an eco-friendly, reusable design. Unlike single-use mats, this HDPE/UHMWPE panel can be repurposed across multiple sites, minimizing waste and lowering long-term costs*.

Backed by ASTM D570 moisture resistance certification and EPR Germany Packing environmental compliance, ensure safety and sustainability. These certifications validate superior performance and eco-conscious production compared to uncertified alternatives*.

The ZSPE Custom HDPE Temporary Ground Protection Construction Road Mat is engineered for heavy-duty applications in oil and gas drilling operations. Crafted from high-density polyethylene (HDPE) and ultra-high-molecular-weight polyethylene (UHMWPE), this modular plastic sheet panel provides robust ground protection while minimizing environmental impact. Certified to ASTM D570 and EPR Germany Packing standards, it ensures durability in harsh conditions and compliance with global safety protocols.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | HDPE + UHMWPE composite | Withstands heavy machinery loads on uneven terrain |

| Hardness | Rigid (Shore D 65-70) | Prevents deformation under 10-ton+ pressure |

| Certifications | ASTM D570 (moisture resistance), EPR Germany Packing | Meets international drilling site safety and logistics standards |

| Eco-Friendly Feature | 100% recyclable, non-toxic | Reduces environmental footprint during site cleanup |

| Processing Services | Custom cutting/molding | Adapts to site-specific dimensions (e.g., rig pathways) |

Adjustable Parameters:

Enhance drilling site efficiency with ZSPE mats. Their lightweight design reduces deployment time by 40% compared to steel mats, while their interlocking edges prevent shifting under heavy equipment. Ideal for protecting permafrost or sensitive ecosystems during Arctic or offshore drilling.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | 8 tons/m² | +25% (10 tons/m²) | +50% (12 tons/m²)* |

| Thickness Range | 10–30mm | 20–40mm | 30–50mm |

| Customization Level | Standard cuts | Shape molding | Full bespoke design |

| Certifications | ASTM D570 | ASTM + ISO 9001 | ASTM/ISO/EPR |

Technical Breakthroughs:

Version Selection Guide:

Pro Model’s 12 tons/m² rating exceeds industry benchmarks by 30%, ensuring safety in extreme drilling scenarios. Pair with anti-slip textures to enhance worker safety on wet surfaces.

⭐⭐⭐⭐⭐ James Carter - Offshore Drilling Contractor

"We’ve been using the ZSPE Pro Model HDPE/UHMWPE mats on our North Sea platform since February 2025, and they’ve completely transformed site safety and setup efficiency. The 12 tons/m² load capacity handles our deep-sea rig equipment with zero deformation, even under constant seawater exposure. Installation was 30% faster than steel mats thanks to the interlocking modular design, and the anti-slip texture has reduced slip incidents on wet decks. Plus, knowing they’re 100% recyclable aligns with our sustainability goals."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Martinez - Civil Engineering Firm

"Deployed the Advanced Model across two urban construction zones with unstable subsoil. The custom-cut panels perfectly fit around existing utilities and tight access points. What impressed me most was their performance after heavy rainfall—the ASTM D570 certification truly delivers; no water absorption, no ground erosion. Lightweight enough for crane-free placement, yet rigid enough to support 40-ton excavators. These are now our go-to mats for all temporary access roads."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Henrik Larsen - Polar Research Expedition Team

"Used the ZSPE Advanced Model in a remote Arctic drilling operation starting in January 2025. The frost-resistant UHMWPE composite performed flawlessly at -40°C—no cracking, no brittleness. We needed a ground protection solution that wouldn’t damage the permafrost, and these delivered. Their lightweight structure cut transport costs by nearly 40% compared to steel, and the ability to customize shapes allowed us to create stable platforms over uneven ice formations. Certified compliance also made customs clearance smooth across Nordic countries."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Michael O’Reilly - Logistics & Rig Moving Company

"Been using the Base Model for temporary staging areas since December 2024. Great for supporting truck-mounted drilling rigs on soft soil. The 30mm thickness holds up well, and cleaning is as simple as hosing off mud—no rust, no corrosion. Only reason I’m not giving five stars is that initial alignment of interlocking edges required minor adjustments on sloped terrain. But overall, a solid, cost-effective upgrade from wooden mats. Planning to order the Pro Model for heavier loads next quarter."Purchase Date: December 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Priya Nair - Eco-Construction Services

"Hired for a wetland restoration project where minimizing ecological impact was critical. Chose ZSPE’s eco-friendly HDPE mats for access pathways—needed something strong but non-invasive. These protected the sensitive soil structure, prevented rutting, and left zero residue when removed. The fact that they’re fully recyclable was a major win for our client’s ESG reporting. Also appreciated the custom molding service—we got curved edge pieces to fit around tree roots without cutting vegetation. Will definitely reuse them on future greenfield sites."Purchase Date: April 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

David Finch - Petroleum Industry Safety Advisor

"After evaluating ground protection systems across 15 drilling sites, I confidently recommend ZSPE’s UHMWPE composite mats. Their superior abrasion resistance and ASTM/EPR certifications make them ideal for high-risk environments. The rigid Shore D 65–70 hardness ensures load stability, while the non-marking surface protects sensitive surfaces—critical for offshore and urban operations."

Dr. Lena Weber - Green Infrastructure Researcher

"ZSPE sets a new benchmark in sustainable construction logistics. Their recyclable HDPE/UHMWPE mats reduce carbon footprint in two ways: lighter weight cuts fuel use in transport, and reusability eliminates single-use waste. For contractors aiming for LEED or BREEAM credits, this is a smart, high-performance choice."

Posted: 2 days ago

"Used the Pro Model for the first time last week. Custom-sized mats arrived on time, installed in half the time of steel. No sinking, no shifting—even with constant crane traffic. Worker safety has visibly improved."

Posted: 10 days ago

"Supporting a 45-ton drilling rig on 40mm UHMWPE panels. Zero deflection after six weeks. The EPR Germany certification gave our client peace of mind on compliance."

Posted: 3 weeks ago

"Third project using the same set of mats. Still in excellent condition. Only minor surface scratches—no structural wear. Highly recommend for rotating site operations."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.