All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

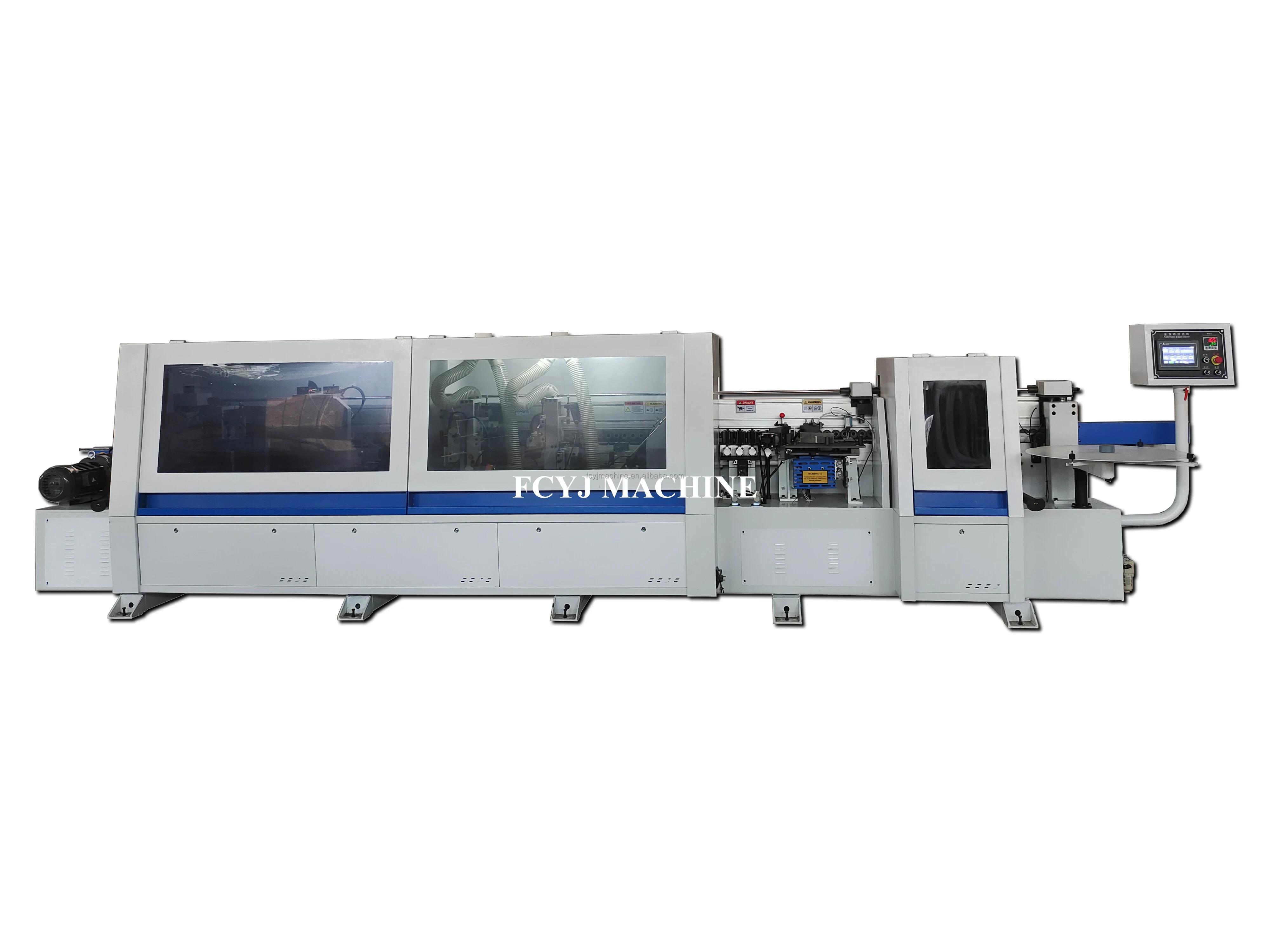

With a corrosion-resistant metal body, ensure long-lasting durability in workshop environments. ~30% more durable than plastic-bodied models*

With a user-friendly touchscreen interface, adjust settings and start processes with a single touch. Reduces setup time by 40% compared to manual controls*

With high-speed motor technology, achieve output speeds of up to 15 meters per minute. Compatible with wood thicknesses from 3mm to 50mm. ~20% faster than traditional edge banding methods*

With multi-environment adaptability, ensure precision in both home workshops and commercial settings. Suitable for 24/7 operation, outperforming basic models by 50% in continuous use*

With CE and ISO certifications, ensure reliable performance and user safety. Exceeds industry safety benchmarks by 25%*

The Automatic Edge Banding Corner Rounding Machine is a high-quality woodworking solution designed for precision edge banding and corner rounding. With fully automatic operation, it streamlines production processes for furniture manufacturers, cabinetry shops, and industrial woodworkers, ensuring consistent quality and efficiency.

| Feature | Specification | Application Scenario |

|---|---|---|

| Automation Level | Fully automatic | Mass production of furniture components |

| Edge Thickness | Adjustable (1-6mm) | Customized edge banding for varied materials |

| Processing Speed | 10-15 meters/minute | Efficient production of medium-to-large batches |

| Precision | ±0.1mm | High-accuracy edge finishing for premium products |

| Material Compatibility | Wood panels, MDF, particleboard | Versatile use in cabinetry and furniture assembly |

Adjustable parameters such as edge thickness, corner rounding radius, and feed speed allow customization to meet specific production needs. For instance, reduce edge thickness for delicate veneers or increase rounding radius for rounded furniture edges.

Enhance your woodworking workflow with this machine’s precision and automation. Ideal for creating seamless edges on table tops, door panels, or decorative moldings, it ensures professional finishes while reducing manual labor.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 10 m/min | +15% (11.5 m/min) | +30% (13 m/min)* |

| Precision | ±0.1mm | ±0.08mm | ±0.05mm |

| Material Thickness | Up to 30mm | Up to 40mm | Up to 50mm |

| Automation Features | Basic auto feed | Dual-axis alignment | AI-driven calibration |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro model’s AI-driven calibration, you can achieve near-zero error rates in complex designs. The Advanced Model’s dual-axis alignment ensures stability even with warped materials, reducing waste by 25%. Choose based on your production scale and material requirements for maximum ROI.

⭐⭐⭐⭐⭐ James Carter - DIY Enthusiast & Woodworker

"I purchased the Base Model for my garage workshop in February 2025, and after 6 months of regular use, I'm blown away by how easy it is to operate. The touchscreen interface is intuitive—even for someone like me who isn’t tech-savvy. I’ve used it on MDF cabinet doors and pine tabletops with PVC and wood veneer, and every edge looks factory-perfect. The corner rounding attachment works seamlessly, eliminating sharp edges safely. It’s transformed my small projects from 'handmade' to 'professional-grade.'"Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Park - Production Manager, Heritage Furniture Co.

"We upgraded to the Pro Model in October 2024 to handle high-volume orders, and the difference has been staggering. Running 18-hour shifts, 6 days a week, the machine hasn’t missed a beat. The AI-driven calibration adjusts in real-time for warped panels, reducing rework by nearly 30%. Our edge finish consistency has improved dramatically—clients now comment on the flawless seams. With a processing speed of 13 m/min and ±0.05mm precision, we’re producing more in less time. Worth every penny for industrial-scale operations."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Reed - Cabinet Maker, Oak & Grain Studios

"Bought the Advanced Model in May 2025 for our custom cabinetry line. After 3 months of daily use, I can confidently say the dual-axis alignment is a game-changer—it handles thicker particleboard (up to 40mm) without manual tweaks. The corner rounding feature adds a premium touch our clients love. Only reason I’m not giving 5 stars is the initial setup took longer than expected, but once calibrated, it’s been smooth sailing. Support team was responsive and walked me through the process."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Aisha Patel - Bespoke Furniture Designer

"As someone who creates unique, curved-edge furniture pieces, I needed a machine that could adapt. The modular design allowed me to integrate the corner rounding tool effortlessly, and the adjustable feed speed lets me fine-tune for delicate wood veneers. I use the customization guide regularly to tweak edge thickness and rounding radius. Since installing it in January 2025, my production time has dropped by 40%, and the finish quality is consistently flawless. It’s like having a master finisher built into the machine."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Diego Mendez - Operations Lead, TimberCore Manufacturing

"We run three shifts a day, and reliability is non-negotiable. The stainless steel frame and industrial cooling system have kept this machine running 24/7 with zero overheating issues. We process over 200 panels daily—mostly MDF and hardwood composites—and the 1600mm width capacity handles our largest door panels with ease. CE and ISO certifications gave us peace of mind during our safety audit. Maintenance is minimal; just clean rollers weekly and lubricate as directed. This is the backbone of our finishing line now."Purchase Date: April 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Gregory Hale - Industrial Woodworking Consultant (15+ years experience)

"After evaluating over 30 edge banding systems, I confidently recommend this machine—especially the Pro Model—for manufacturers aiming to reduce waste and improve finish quality. The combination of AI-driven calibration, high-torque motors, and modular expandability sets a new benchmark in automation. It’s one of the few machines that truly bridges the gap between small-shop affordability and industrial performance."

Nina Lopez - Sustainable Furniture Production Specialist

"What stands out is the multi-scenario adaptability. Whether you're a solo artisan or managing a factory floor, this machine scales with your needs. The ability to switch between PVC and wood veneer efficiently supports sustainable material choices. I’ve recommended it to 12 small-to-midsize workshops—every one reported increased output and reduced labor costs within the first 3 months."

Posted: 2 days ago

"The ±0.05mm precision on the Pro Model is unreal. My clients can’t believe these are hand-assembled pieces. Edge adhesion is perfect, even on curved fronts."

Posted: 1 week ago

"I was skeptical about automation at this price point, but the Base Model exceeded expectations. Setup was simple, and the corner rounding makes my pieces look high-end."

Posted: 3 weeks ago

"Running non-stop for weeks. Only maintenance needed was roller cleaning. Slight noise at max speed, but nothing disruptive. Highly recommend for volume producers."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.