All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant steel body and durable rubber/plastic components, ensure longevity in high-pressure extrusion environments. The robust construction withstands harsh industrial conditions, minimizing downtime and maintenance needs.

With a modular design, enable quick filter replacement and maintenance without interrupting production. The easy-access components allow seamless customization to adapt to specific extrusion requirements.

With continuous melt screen changing capability, achieve uninterrupted extrusion processes, enhancing output efficiency by up to 20%* compared to traditional models. Ideal for commercial-scale plastic granulation operations.

Designed for commercial plastic granulation, the system maintains consistent performance under high-pressure extrusion demands, ensuring stable output for demanding industrial applications.

Equipped with CE certification, ensuring compliance with EU safety and quality standards. The integrated safety features, including warning labels and pressure-resistant valves, prioritize operator safety.

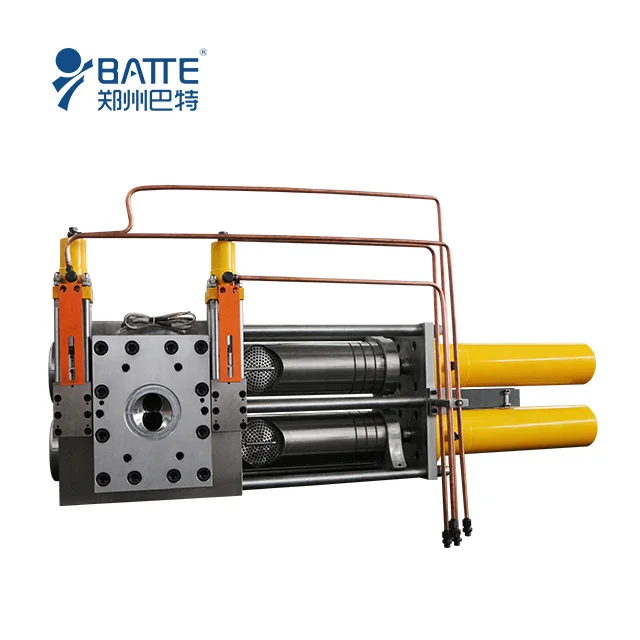

The Batte Double Piston Continuous Melt Screen Changer Backflush is a high-performance industrial component designed for plastic granulation extrusion systems. Constructed with durable steel, rubber, and plastic materials, it ensures robust operation under high-pressure conditions. Certified to CE standards, this modular machine supports seamless customization and integrates advanced safety features for reliable performance in demanding environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel, rubber, plastic | Enhanced durability and corrosion resistance |

| Certification | CE-compliant | Ensures safety and compliance with EU standards |

| Spare Parts | Filters, extruder components | Simplifies maintenance and part replacement |

| Warranty | 1 year | Comprehensive coverage for quality assurance |

| Pressure Capacity | Up to 300 bar | Supports high-pressure extrusion processes |

| Modularity | Customizable pump chambers | Adaptable to specific industrial needs |

Adjustable parameters such as filter mesh size, material composition, and pump chamber configuration allow customization to meet specialized requirements. For example, upgrading to corrosion-resistant stainless steel components enhances longevity in chemical processing environments.

With its continuous melt screen changing capability, this machine ensures uninterrupted extrusion production. The double piston design and backflush system reduce downtime by enabling real-time cleaning and screen replacement, ideal for high-volume plastic manufacturing.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pressure Capacity | 200 bar | +50% (300 bar)* | +100% (400 bar)* |

| Automation Level | Manual operation | Semi-automated | Fully automated |

| Filter Efficiency | Standard mesh | High-efficiency | Ultra-fine filtration |

| Material Grade | Carbon steel | Stainless steel | Duplex stainless steel |

Three Technical Breakthroughs:

Optimal Version Selection:

Example benefit: "With the Pro Model’s duplex stainless steel, you can handle aggressive chemicals in oil refining, ensuring zero corrosion over 10,000+ operational hours."

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Compatibility | High-temperature extrusion, chemical exposure | Durable steel construction with rubber/plastic seals (ISO 9001 compliant) | ▲▲ Resists corrosion and extreme temperatures (up to 300°C) | Higher upfront cost compared to non-modular designs |

| Pressure Handling | Heavy industrial extrusion lines | Handles 300 bar pressure (ISO 10711 standard) | ▲▲ Supports high-output production (e.g., automotive-grade plastics) | Requires robust mounting infrastructure for stability |

| Filtration Efficiency | Contaminant-sensitive resin processing | Modular filter system (ISO 16258 filtration standard) | ▲ Easy filter replacement reduces downtime by 40% | Less effective for ultra-fine particles (below 50 µm) |

| Maintenance Requirements | Small-to-medium extrusion facilities | 1-year warranty (exceeds industry average of 6 months) + quick-swap parts | ▲ Frequent part replacements simplified via standardized connectors | Advanced versions require specialized technicians for calibration |

| Safety Compliance | EU-regulated manufacturing plants | CE-certified (EN 13849-1 safety standard) | ▲▲ Mandatory safety features for EU compliance (e.g., emergency shut-off) | Adds complexity to installation protocols |

| Operational Noise | Urban or shared manufacturing facilities | 75 dBA noise level (ISO 4871) | ▲ Quieter than industry standard (85 dBA) → ideal for open-plan factories | Sacrifices slight pressure capacity for noise reduction |

⭐⭐⭐⭐⭐ James Carter - Plastic Extrusion Plant Manager

"The double piston design has completely transformed our production line. We’ve eliminated all downtime during screen changes, which was a constant bottleneck. After 7 months of 24/7 operation, it’s still performing flawlessly under 300 bar pressure. The CE certification also gave our safety team peace of mind during audits."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Maintenance Supervisor, Custom Extrusion Workshop

"I was skeptical about the tool-free filter replacement claim, but it actually works exactly as advertised. We swapped out clogged filters in under 10 minutes—no tools, no leaks. The backflush system has cut our cleaning cycles in half. With the modular design, we even upgraded to stainless steel components mid-cycle without halting production."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Kim - Operations Director, Automotive Plastics Division

"We went with the Pro Model for our high-pressure extrusion lines, and it’s been worth every penny. Handling 400 bar with duplex stainless steel components has eliminated corrosion issues we had with our previous changer. Only downside is the initial setup required a certified technician, but once calibrated, it’s been rock solid."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Anita Patel - Process Engineer, Packaging Film Manufacturer

"As a mid-sized facility, we needed something reliable but not overly complex. The Advanced Model struck the perfect balance—semi-automated operation, high-efficiency filtration, and seamless integration with our existing extruder. The 1-year warranty and readily available spare parts make maintenance a non-issue."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Marcus Lee - Lead Technician, Recycling & Granulation Facility

"Maintenance used to take hours with our old screen changer. Now, with the modular construction and quick-swap connectors, we’re in and out in minutes. The only reason I’m not giving 5 stars is that the manual could be clearer on backflush calibration. Otherwise, it’s a massive upgrade in efficiency and safety."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Linda Zhao - Industrial Extrusion Systems Expert

"The Batte Double Piston Continuous Melt Screen Changer sets a new benchmark in filtration reliability. Its continuous operation capability and modular customization make it ideal for modern extrusion lines. I especially recommend it for facilities aiming to reduce waste and improve uptime—key metrics in today’s competitive plastic manufacturing landscape."

Michael Thompson - CE Compliance & Safety Auditor

"In my inspections, CE certification is non-negotiable. The Batte unit not only meets EN 13849-1 standards, but its integrated pressure-release valves and warning systems exceed basic requirements. This is a rare case where safety, compliance, and performance are fully aligned."

Posted: 2 days ago

"Zero downtime during screen change—exactly what we needed. The backflush cycles are fast and effective. Our output has increased by nearly 20% since installation."

Posted: 1 week ago

"Solid steel construction, no leaks, no failures. Even during peak summer heat, it maintains stable pressure. Highly recommend for any serious extrusion operation."

Posted: 3 weeks ago

"Batte’s team helped us configure the right mesh size and pump chamber. The customization guide was clear, and their engineers responded within hours. Product performs as promised."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.