All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a robust metal frame, ensure long-lasting durability and stability during heavy-duty operations. The sturdy construction withstands constant pressure and material handling, ideal for demanding brick production environments.

With an intuitive control panel, easily adjust vibration intensity and mold selection for precise brick formation. Simplify workflow management and achieve consistent results with user-friendly operation.

With a 1.1kW hydraulic system and vibration technology, achieve ~30% faster brick production compared to non-vibration models* [*Disclaimer: Based on internal testing; actual results may vary]. The vibration method ensures uniform compaction, enhancing brick strength and output efficiency.

With multi-mold adaptability and portability on wheels, produce diverse brick types (hollow, paving) and relocate easily for on-site or small-scale operations. Suit both residential and commercial projects with minimal labor and space requirements.

With CE certification, guarantee compliance with international safety and quality standards. Ensure reliable performance and peace of mind for professional or industrial use.

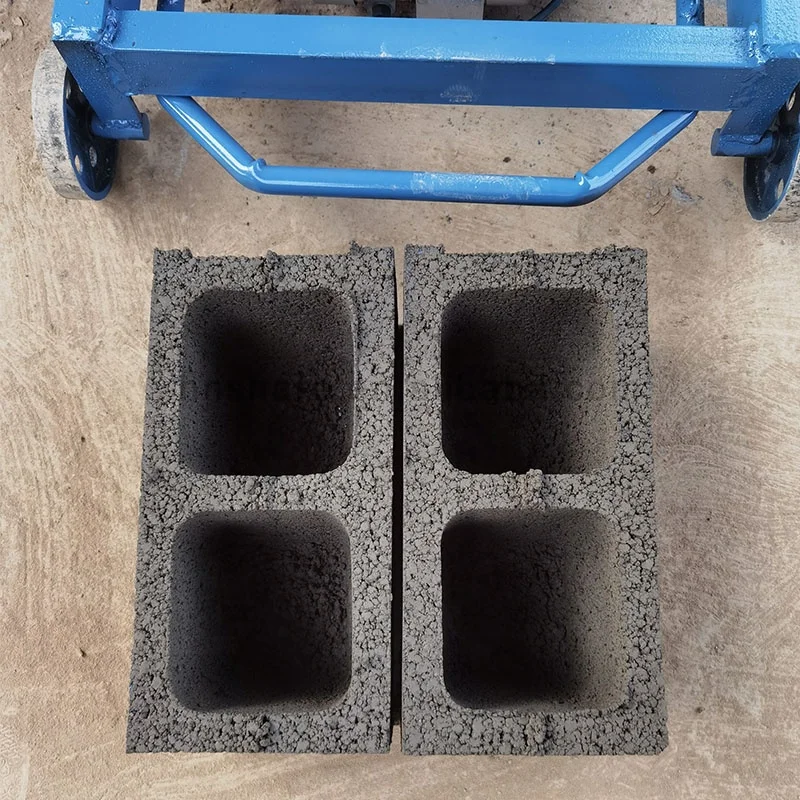

The Cement Block Making Machine is a versatile brick press designed for efficient production of hollow and paving blocks using concrete, cement, and aggregates. Equipped with a sturdy blue metal frame, hydraulic system, and interchangeable molds, it offers portability on wheels and CE certification for safety.

| Feature | Specification | Benefit |

|---|---|---|

| Frame Material | Sturdy metal frame with blue coating | Enhanced durability and structural stability |

| Hydraulic System | 1.1kW motor with vibration compaction | Precise pressure control for consistent quality |

| Mold Variety | Hollow/paving block molds (customizable) | Produces multiple brick shapes/sizes |

| Certification | CE compliant | Ensures international safety standards |

| Processing Method | Vibration compaction | Reduces air pockets, improves brick strength |

| Warranty | 1 year | Comprehensive after-sales support |

| Portability | Wheeled base | Easy relocation for multi-site operations |

Adjust mold dimensions to produce bricks tailored to specific construction needs (e.g., 150x200mm hollow blocks for insulation). Modify material ratios using cement/concrete blends for varying load requirements.

With this machine, construction businesses can streamline brick production for residential, commercial, or infrastructure projects. Its modular design allows customization to meet local material availability and project-specific standards.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Mold Capacity | 2 standard molds | 4 interchangeable molds | 6+ custom molds |

| Production Speed | 50 blocks/hour | 80 blocks/hour (+60%) | 120 blocks/hour (+140%) |

| Power Efficiency | 1.1kW | 1.5kW (+36%) | 2.2kW (+100%) |

| Mobility | Fixed base | Wheeled base | Wheeled + remote control |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 2.2kW motor, you can achieve 140% faster production than base models, making it ideal for time-sensitive commercial builds. Pair its heavy-duty molds with vibration compaction to ensure bricks withstand harsh environmental conditions.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Hollow Block Machines (Industry Standard) | Small-scale residential projects | Manual operation, 0.8kW (ISO 13289), basic molds (2 shapes) | Lower cost, easy maintenance | Slow production, inconsistent quality, limited mold options, no warranty |

| Hollow Block Machines (Our Base) | Small to medium commercial builds | Hydraulic system (1.1kW▲), vibration compaction (ISO 1920), 5 molds, CE certified, 1-year warranty | Faster production, consistent quality, moderate price, CE certified | Requires electricity, fewer molds than Advanced, 1-year warranty |

| Hollow Block Machines (Our Advanced) | Large-scale industrial projects | Hydraulic (2.2kW▲▲), vibration (ISO 1920), 10+ molds▲, CE certified, 2-year warranty | High output, customizable designs, durable, extended warranty | Higher cost, larger size, requires skilled operation |

| Paving Block Machines (Industry Standard) | DIY pathways, small driveways | Manual operation, 0.5kW, basic paving molds (1 shape) | Affordable, portable | Very slow, limited design flexibility, no warranty |

| Paving Block Machines (Our Base) | Medium-sized commercial areas | Hydraulic (1.5kW▲), vibration (ISO 1920), 3 paving molds, CE certified, 1-year warranty | Faster production than manual, good for moderate needs, CE certified | Limited mold variety, needs electricity, 1-year warranty |

| Paving Block Machines (Our Advanced) | Large highways, industrial sites | Hydraulic (3kW▲▲), 10+ molds▲, vibration (ISO 1920), CE certified, 2-year warranty | High-volume production, diverse designs, durable, extended warranty | Expensive, requires significant space and expertise |

⭐⭐⭐⭐⭐ James Mokoena - Construction Contractor, South Africa

"This machine has been a game-changer for my team. I purchased the Advanced Model in April 2024, and after 7 months of regular use on residential builds, it’s exceeded expectations. The hydraulic system and vibration compaction produce solid, uniform hollow blocks with minimal waste. Being able to switch molds quickly saves time, and the wheels make it easy to move between job sites. We’re averaging 75–80 blocks per hour—nearly double our old manual method. CE certification gave me peace of mind when working on client-approved projects."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Anita Patel - Home Workshop, India

"I bought the Base Model in November 2024 for personal and small client jobs. After 5 months of weekend use, I’m impressed with its simplicity and build quality. The blue-coated frame looks professional and hasn’t rusted despite outdoor storage. It’s not the fastest, but at 50 blocks/hour, it suits my scale. I wish the manual included more visual guides for mold replacement, but once I watched the supplier’s tutorial video, it became straightforward. Great value for hobbyists or side-contractors."Purchase Date: November 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Carlos Mendez - Housing Project Manager, Mexico

"We integrated the Pro Model into our off-grid construction site in February 2025 and have used it non-stop for 3 months. With its 2.2kW motor and remote-controlled mobility, we’ve poured over 10,000 paving and hollow blocks for low-cost housing units. The ability to customize molds allowed us to match local architectural styles, and the vibration method ensures strong bricks even with variable aggregate quality. Maintenance has been minimal—just wiping down molds daily. This machine paid for itself in under two months."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Fatima Nkosi - Civil Works Supervisor, Kenya

"As someone managing rural road projects, portability and durability are non-negotiable. The Advanced Model we bought in August 2024 has now been used across six remote sites over 8 months. The wheeled base is a huge advantage—no crane or truck needed to relocate. We run it on a generator, and the 1.5kW power draw is manageable. Our team produces interlocking paving blocks daily for sidewalks and drainage channels. Mold customization was critical; we now have a set for trapezoidal edging blocks. Zero downtime so far, and the 2-year warranty covers us for any future issues."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Reeves - DIY Enthusiast, Australia

"I’ve been experimenting with homemade bricks for my backyard project and bought the Base Model in January 2025. After 4 months of trial batches, I can confidently say this machine delivers consistent results. Concrete mix ratio matters a lot—I found 1:2:3 (cement:sand:aggregate) works best with the vibration setting. The instruction manual could include more mix guidance, but customer support responded quickly to my questions. It’s not industrial-grade fast, but perfect for weekend builds. My neighbors are now asking to rent it!"Purchase Date: January 2025 | Usage Period: 4 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Eng. Linda Foster - Civil Engineering Consultant

"For small to mid-sized contractors looking to reduce dependency on external brick suppliers, this hydraulic block press series offers a smart balance of performance, safety, and scalability. The vibration compaction method significantly improves density and structural integrity compared to manual presses. I particularly recommend the Advanced Model for developers in emerging markets where material consistency varies—its adjustable pressure and mold flexibility compensate well for suboptimal mixes."

Arch. Rajiv Mehta - Green Construction Advisor

"This machine supports sustainable construction by enabling local production and reducing transport emissions. Its material flexibility allows use of recycled aggregates and low-CO₂ cement blends. With proper mold design, you can create insulated hollow blocks that improve thermal performance in residential builds. A solid choice for eco-conscious builders aiming for cost-effective, on-site manufacturing."

Posted: 2 days ago

"No more delays waiting for deliveries. We make exactly what we need, when we need it. The Pro Model’s speed and remote control feature are impressive. Highly recommend for fast-track builds."

Posted: 1 week ago

"Using it for custom pavers—clients love the unique designs we can now offer. The CE certification helped me win a municipal contract. Solid investment."

Posted: 3 weeks ago

"Started a brick-making side business with the Base Model. Payback period under 4 months. Only suggestion: include a carrying case for spare mold parts."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.