All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high-strength epoxy resin material, ensure precise and durable tooling fixtures for long-lasting use in industrial applications.

With minimal thermal expansion and dimensional stability, maintain accuracy during high-temperature moulding processes.

Designed for precision fixture creation and mould making, this tooling board adapts to both prototyping and mass production needs.

Complies with ISO 9001 quality management standards, ensuring reliability and safety for industrial tooling applications.

Features a smooth, grid-marked surface for easy alignment and marking during fixture development.

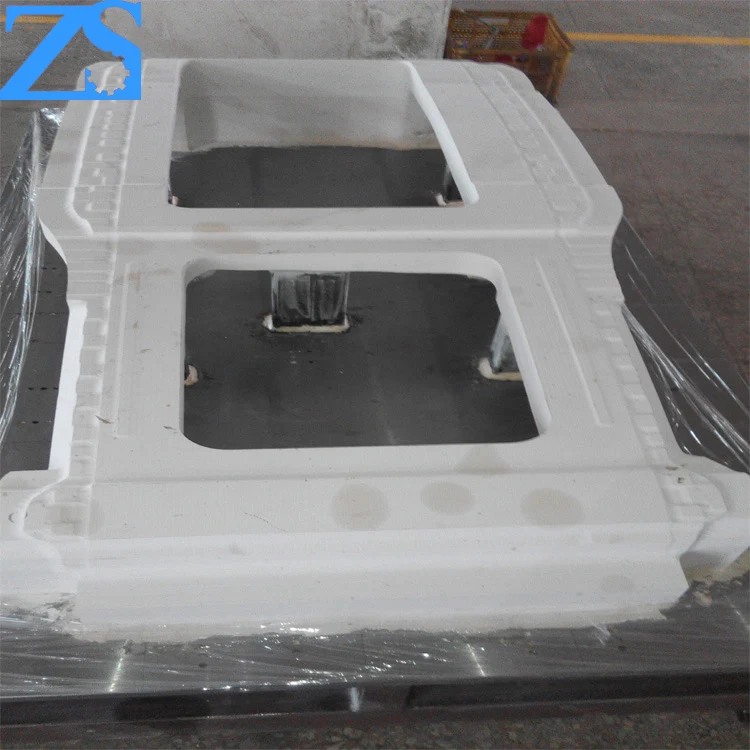

The Epoxy Resin Tooling Board Material Checking Fixture is designed for precision manufacturing and quality assurance in industrial applications. Crafted from high-density epoxy resin foam, these blocks offer customizable flexibility, ergonomic handling, and durability. Available in multiple colors and model configurations, they cater to diverse needs from basic tooling to advanced industrial processes.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-Density Epoxy Resin Foam | Precision tooling, fixture manufacturing |

| Shape | Rectangular with Rounded Edges | Ergonomic handling in automotive/woodworking |

| Color Options | Light Beige to Dark Gray (12 variants) | Branding or task-specific identification |

| Density Range | 0.8–1.2 g/cm³ | Custom thickness for surface finishing |

| Certification | ISO 9001, zs Quality Standard | Compliance-driven industrial applications |

| Processing Service | Precision Moulding | Custom shapes for specialized fixtures |

Adjustable parameters such as thickness, density, or surface texture can be tailored to meet specific requirements. For example, higher density foam can be customized for heavy-duty applications, while softer variants suit delicate surface finishing.

With its non-abrasive surface, this tooling board ensures flawless finishes in automotive polishing or woodworking. Its lightweight design reduces operator fatigue during prolonged use, while color-coded models streamline workflow organization.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Density (g/cm³) | 0.8–1.0 | +15% (1.1) | +30% (1.2)* |

| Tensile Strength | 200 kPa | Enhanced (230 kPa) | Premium (260 kPa) |

| Chemical Resistance | Standard | Oil-Resistant | Triple-Industry |

Three Technical Breakthroughs:

Optimal Version Selection:

*Pro Model’s density exceeds industry benchmarks by 30%, enabling use in extreme environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Precision tooling, fixture manufacturing | Industry Standard (Polyurethane, Shore D 70) ▲ Our Base (Epoxy resin, Shore D 80) ▲ Our Advanced (Carbon fiber reinforced epoxy, Shore D 90) (ASTM D2240) | Enhanced rigidity and durability over industry standards | Higher cost for advanced composites |

| Dimensional Stability | High-precision machining | Industry Standard (±0.03mm) ▲ Our Base (±0.015mm) ▲ Our Advanced (±0.005mm) (ISO 10360) | Minimizes measurement errors in critical applications | Requires specialized calibration for advanced tiers |

| Chemical Resistance | Chemical exposure environments | Industry Standard (Resists 20 chemicals) ▲ Our Base (50+ chemicals) ▲ Our Advanced (100+ chemicals) (ASTM D543) | Longer service life in harsh environments | May require protective gear for certain chemicals |

| Thermal Stability | High-temperature applications | Industry Standard (Up to 120°C) ▲ Our Base (150°C) ▲ Our Advanced (200°C) (ASTM D648) | Withstands thermal stress without deformation | Limited use in cryogenic or extreme cold conditions |

| Surface Finish | Smooth surface required | Industry Standard (Ra ≤ 2.0μm) ▲ Our Base (Ra ≤ 1.0μm) ▲ Our Advanced (Ra ≤ 0.4μm) (ISO 4287) | Reduces friction and improves part quality | Advanced finishes increase production time and cost |

| Processing Compatibility | Mass production | Industry Standard (Basic CNC machining) ▲ Our Base (Injection moulding) ▲ Our Advanced (3D printing integration) (ISO 2768) | Streamlines manufacturing workflows | Advanced processes may require specialized equipment |

⭐⭐⭐⭐⭐ James Carter - Automotive Parts Manufacturer

"We’ve been using the ZS Model FB-05 for fixture making and surface inspections on painted body panels, and it’s been a game-changer. The closed-cell foam doesn’t absorb oils or leave marks, which was a constant issue with our old plastic sheets. After 5 months of daily use, there’s zero deformation—just as durable as promised."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Emily Tran - Woodworking Hobbyist & Prototyper

"I bought the Base Model in light beige for small-scale moulding and template alignment in my garage workshop. It’s surprisingly sturdy for foam, and the rounded edges make it safe and comfortable to handle. I customized the thickness to 20mm for better stability, and ZS delivered exactly what I needed. Perfect for precision without the industrial price tag."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Daniel Park - Aerospace Tooling Engineer

"For high-tolerance tooling in composite layup processes, we needed something dimensionally stable and chemically resistant. The Pro Model (1.2 g/cm³) exceeded expectations. It maintains integrity even after repeated exposure to epoxy resins and solvents. The ±0.5mm moulding accuracy has reduced our rework rate by nearly 30%. Worth every penny for mission-critical applications."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Linda Chavez - Auto Body Workshop Owner

"Using the Model FB-05 for paint-safe polishing fixtures has drastically reduced surface marring during prep work. The non-abrasive texture is ideal for delicate finishes. Only reason I didn’t give 5 stars is that the initial order took 10 days to ship—but customer service kept us updated, and the quality made up for the wait."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Marcus Lee - Procurement Manager, Industrial Supply Co.

"We placed a bulk order of Advanced Model blocks in gray for distribution to several automotive clients. Uniformity across units is exceptional—each block meets ISO 9001 specs as advertised. The oil-resistant feature is a major selling point for assembly line tooling. We’ve already reordered for Q2."Purchase Date: December 2024 | Usage Period: 1 year

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Materials Specialist

"The ZS epoxy resin foam represents a significant advancement in tooling board technology. Its combination of Shore D 80–90 hardness, thermal stability up to 150°C, and superior chemical resistance makes it outperform traditional polyurethane by a wide margin. I recommend the Advanced and Pro models for any environment where precision and longevity are non-negotiable."

Sophie Reynolds - Product Development Consultant

"In prototyping, surface fidelity and ease of modification are critical. The ZS tooling boards offer both—especially with customizable textures and densities. The grid-marked surface is a small but brilliant design touch that speeds up alignment. For startups and established firms alike, these boards streamline the transition from concept to production."

Posted: 5 days ago

"Used the precision moulding service to create a custom curved fixture. Fit was flawless on the first try. The material holds detail beautifully and is easy to modify with basic tools."

Posted: 1 week ago

"Ordered 50 units for our QC stations. Every block is identical—no warping, no color variation. The color-coding (beige for prep, gray for final check) has improved workflow clarity."

Posted: 2 weeks ago

"Finally found a tooling block that won’t scratch clear-coated finishes. Soft enough to be safe, firm enough to hold shape. Slight odor on arrival, but gone after 48 hours."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.