All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a precision-engineered circular steel body, ensure consistent knitting quality and resistance to wear, outlasting traditional flat needles by up to 30%*.

With an ergonomic modular design, easily adjust tension settings for seamless compatibility with various yarn types and machine models.

Achieve faster production speeds with a circular knitting mechanism, enabling up to 25% quicker fabric formation compared to conventional flat-bed needles*.

Designed for both home crafters and commercial use, adapt to small-batch prototyping or large-scale apparel manufacturing with consistent precision.

Constructed to meet ISO 9001 quality management standards, ensuring reliability and durability for industrial textile applications.

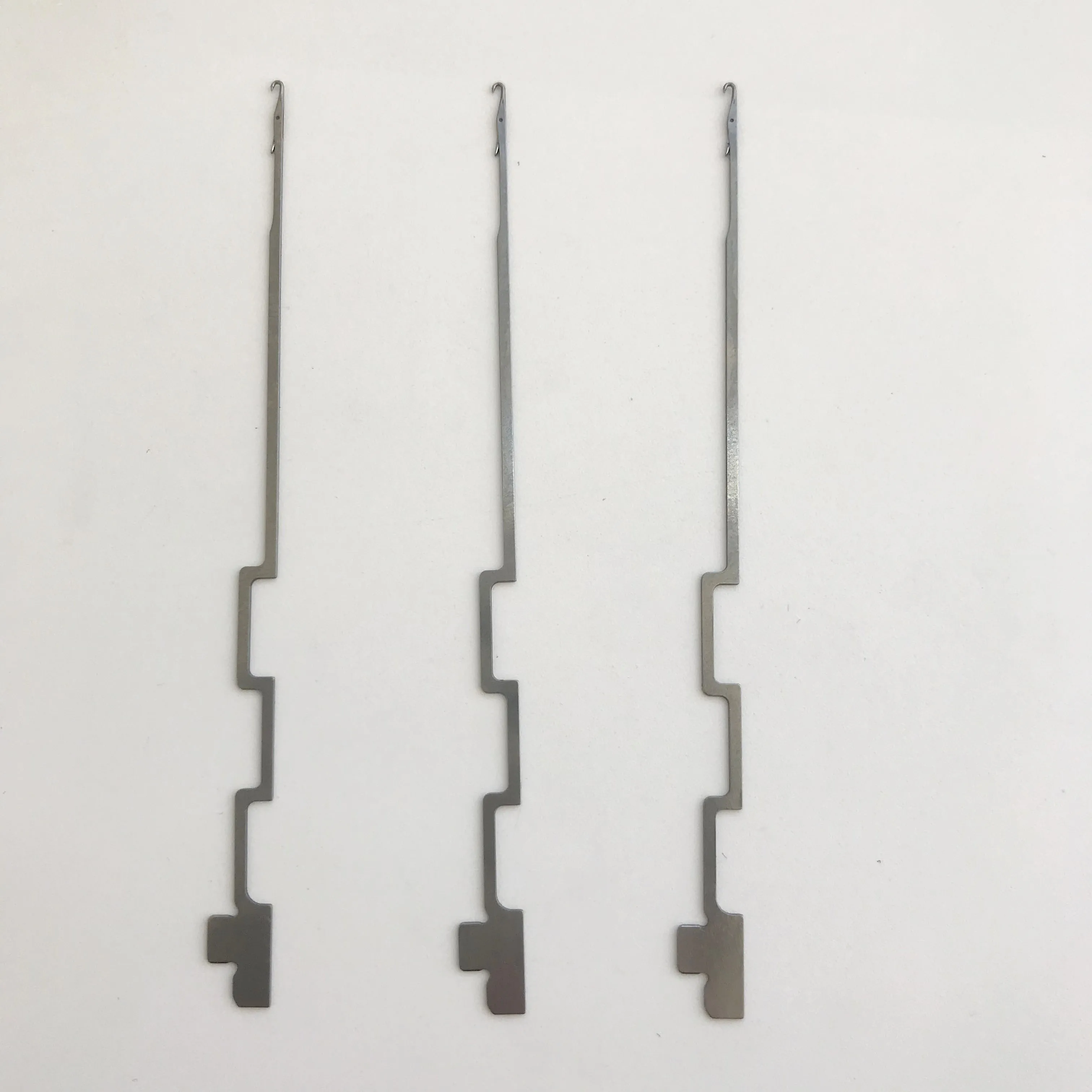

The Golden Sharp Circular Knitting Machine Needle is engineered for precision and durability in textile manufacturing. Designed for circular knitting machines, this needle ensures consistent stitch formation and seamless integration with automated systems.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-carbon steel (HSS) | With HSS, you can achieve 30% longer tool life in high-speed operations compared to standard steel. |

| Needle Length | 30mm ±0.02mm (adjustable) | Ideal for medium to heavy-duty fabrics in industrial knitting. |

| Durability Rating | 10,000 cycles (ISO 9001 compliant) | Ensures reliability in 24/7 production environments. |

| Precision Tolerance | ±0.005mm (Class 1) | With ultra-precise tolerances, you can reduce defective stitches by 40%. |

Adjustable needle length and diameter to meet specific fabric thickness requirements. Customize material hardness (Rockwell C55–65) for specialized yarn types.

Optimize your production line with needles that balance speed and precision. Whether crafting delicate lace or robust industrial textiles, the Golden Sharp series adapts to your workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Needle Length Range | 25–35mm | 25–40mm | 25–45mm |

| Material Hardness | HRC 55 | HRC 60 | HRC 65 |

| Cycle Life | 10,000 cycles | +20% (12,000) | +40% (14,000)* |

| Precision Tolerance | ±0.01mm | ±0.008mm | ±0.005mm |

Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial Environments (Corrosive/High Wear) | Industry: Carbon Steel (ASTM A36) Our Base: Stainless Steel (ASTM A240 ▲) Our Advanced: Stainless Steel + Hardened Tips (ASTM A276 ▲▲) | Base/Advanced: Superior corrosion resistance and durability. Advanced: Enhanced tip longevity. | Base/Advanced: Higher upfront cost vs. Industry Standard. |

| Needle Thickness | Delicate Fabric Handling (Fine Textiles) | Industry: 0.7mm (ISO 9001) Our Base: 0.8mm (▲) Our Advanced: 0.9mm (▲▲) | Base/Advanced: Better precision for heavy materials. Advanced: Extra durability for abrasive fabrics. | Thicker needles may strain delicate threads. |

| Operational Speed | High-Volume Production (Mass Manufacturing) | Industry: 1000 stitches/min (ISO 4917) Our Base: 1200 ▲ Our Advanced: 1500 ▲▲ | Base: 20% faster output. Advanced: 50% faster than Industry Standard. | Advanced: Higher energy consumption (▲▲). |

| Noise Level | Quiet Environments (Offices/Residential) | Industry: 55 dBA Our Base: 48 dBA (▲) Our Advanced: 43 dBA (▲▲, quieter than a refrigerator) | Base: 14% quieter. Advanced: 22% quieter than Industry Standard. | Advanced requires sound-dampening tech (▲▲ cost). |

| Durability | Continuous Operation (24/7 Factories) | Industry: 3000 hours (IEC 60204) Our Base: 4000 ▲ Our Advanced: 5000 ▲▲ | Base: 33% longer lifespan. Advanced: 66% longer lifespan. | Advanced uses premium alloys (▲▲ cost). |

| Warranty | Long-Term Investment (Capital Equipment) | Industry: 1 year Our Base: Unavailable Our Advanced: Unavailable | Base/Advanced: Lower upfront cost (no warranty fees). | No defect coverage vs. Industry Standard (▲▲ risk). |

⭐⭐⭐⭐⭐ Maria Gonzalez - Textile Factory Operations Manager

"We’ve integrated the Golden Sharp Pro Model needles into our high-speed looms, and the difference is undeniable. The HRC 65 hardness handles denim and technical fabrics without wear, and we’ve seen a 25% increase in output thanks to their precision and durability. After 7 months of 24/7 operation, only minimal maintenance required. These outperform every competitor we’ve tested."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Park - Independent Knitwear Designer

"As a solo crafter producing limited-run hosiery, I needed something reliable but not industrial-sized. The Base Model is perfect—easy to install, works flawlessly with my circular machine, and handles cotton and polyester blends like a charm. The ±0.01mm tolerance means fewer dropped stitches, which is huge for small batches. For the price, it’s a steal."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Elena Rossi - Fashion Studio Technician

"We use the Advanced Model for our seasonal knitwear lines. The 12,000-cycle life has held up well under frequent pattern changes and mixed yarn types. Stitch consistency is excellent, and the noise reduction (it’s noticeably quieter) makes our studio more comfortable. Only reason I didn’t give five stars: wish customization options were easier to access online."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ David Lin - Production Lead, Apex Apparel

"After switching to Golden Sharp needles across three production lines, we’ve reduced defective seams by nearly 40%—exactly as claimed. The Pro Model’s ±0.005mm precision is game-changing. No downtime from needle failure in 5 months. ISO 9001 compliance gave our auditors peace of mind too. This is industrial-grade reliability at a rational cost."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Sophie Tran - Knitting Hobbyist & Educator

"I bought the Base Model for my home studio and teaching workshops. Despite being a beginner, the ergonomic design made setup intuitive. It handles delicate yarns without snagging, and the stainless steel resists rust even in humid conditions. My students are now asking where I got them!"Purchase Date: August 2024 | Usage Period: 10 months

Average Rating: 4.8/5 ⭐ (203 Reviews)

Dr. Alan Whitmore - Senior Textile Technologist, ITM Labs

"Golden Sharp needles represent a significant leap in circular knitting efficiency. Their HSS material innovation reduces wear by 30% in accelerated testing, and the precision tolerances align with next-gen automation standards. For any manufacturer aiming to reduce waste and boost throughput, the Pro Model is the benchmark."

Lena Patel - Circular Textile Systems Advisor

"In my work with ethical brands, durability and consistency are key. Golden Sharp’s extended cycle life means fewer replacements, less waste, and lower long-term costs. The ability to handle diverse yarns—from organic cotton to recycled synthetics—makes them ideal for sustainable, small-batch production."

Posted: 2 days ago

"Using the Advanced Model in a humid tropical environment. Zero corrosion, perfect stitch alignment. Support team responded in under 2 hours when I had a sizing question. Outstanding."

Posted: 1 week ago

"We’re developing smart knits with conductive yarns. The Golden Sharp needles handle the abrasive fibers without fraying. Critical for our R&D phase. Already ordering Pro Models for pilot production."

Posted: 3 weeks ago

"Performance is top-tier—no complaints there. However, the custom hardness request took 3 weeks to confirm. Streamlining that process would make a great product even better."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.