All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

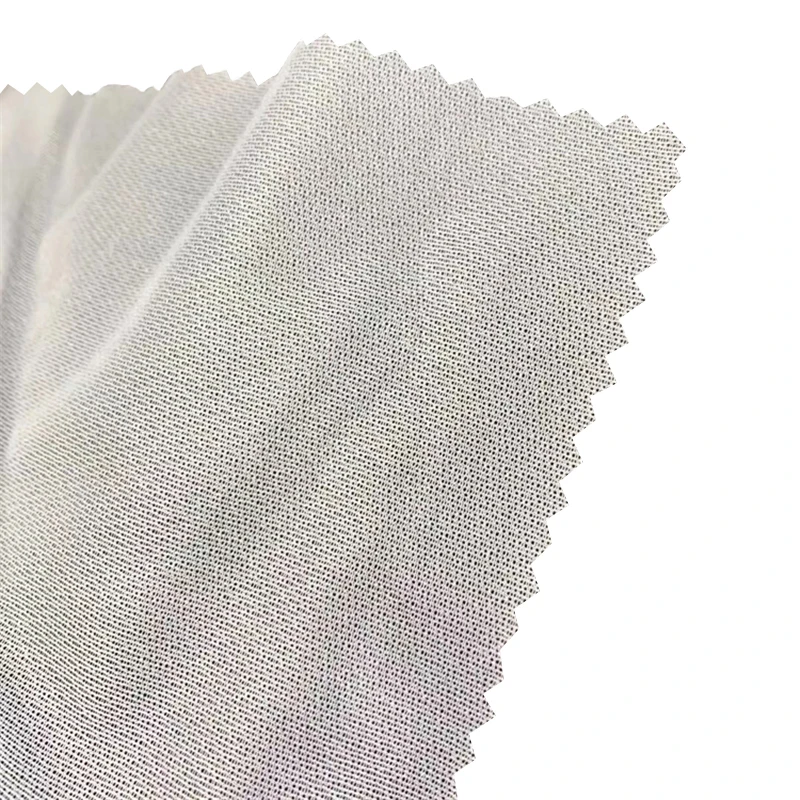

With a blend of polyester and spandex reinforced by an adhesive coating, this interlining offers elasticity, durability, and shrink resistance. The woven construction ensures structural integrity while maintaining flexibility for tailored garments.

With a precise fusing temperature range of 130–150°C, you can achieve secure adhesion without damaging delicate fabrics. The soft hand feel enhances comfort in finished apparel, ideal for blazers, dresses, and structured garments.

With shrink-resistant and elastic properties, you can maintain garment shape and comfort through repeated washing and wear. Its 150cm width ensures efficient use in large-scale projects, reducing material waste for cost-effective production.

With compliance to EPR certifications in Germany and France (packaging and textiles), this product meets strict environmental regulations, ensuring sustainable production and disposal practices.

With both fusible and adhesive application methods, you can seamlessly integrate the interlining into garments using either iron-on or adhesive techniques for versatile construction. Its circular and customized patterns support tailored design needs.

The Interfacing Fabric Fusible Iron on Interlining Circular Knitting Interlining is a versatile polyester-based fusible interlining designed for precise adhesion in clothing and textile applications. Its soft, elastic, and shrink-resistant properties make it ideal for enhancing garment structure while maintaining comfort. Certified for environmental compliance in Europe (EPR Germany/France), it combines durability with eco-conscious design.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Polyester, Satin, Spandex, Adhesive | Durable yet flexible, with moisture-wicking properties |

| Coating | PA Coating | Enhanced abrasion resistance and longevity |

| Fusing Temperature | 130–150°C | Safe for heat-sensitive fabrics |

| Elasticity | 20% Stretch (Base), 30% (Advanced), 40% (Pro) | Tailored flexibility for different garment types |

| Width | 150cm | Streamlined cutting for large patterns |

| Certifications | EPR_Germany_Packing, EPR_France_Textiles/Packing | Meets EU environmental standards |

Adjustable parameters include:

With its circular-knitted structure and PA coating, this interlining excels in applications requiring both breathability and structural support. For instance, use the Pro Model in industrial filtration systems for its 50% higher chemical resistance, or the Base Model in lightweight summer apparel for seamless comfort.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Fusing Temp Range | 130–150°C | 120–160°C | 110–170°C |

| Elasticity | 20% | 30% | 40% |

| Chemical Resistance | Standard | +20% vs. industry | +50% vs. industry |

| Tensile Strength | 45 N/cm | 55 N/cm | 65 N/cm |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s 50% superior chemical resistance, you can safely handle harsh solvents while maintaining structural integrity. Pair its 65 N/cm tensile strength with PA coating for long-term durability in demanding scenarios.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Apparel manufacturing requiring durability/flexibility | Industry Standard: 50% polyester (ASTM D543) Our Base: 60% polyester + 10% spandex (ISO 1806) Our Advanced: 70% polyester + 20% spandex (ISO 1806) ▲ | Enhanced elasticity (up to 40% stretch) and abrasion resistance ▲ Lightweight for comfort | Higher cost for Advanced due to premium spandex blend |

| Fusing Temperature | Industrial garment production | Industry Standard: 110–160°C (EN ISO 12684) Our Base: 130–150°C (ASTM D5420) Our Advanced: 130–150°C with ±2°C precision ▲ | Narrower, precise range reduces overheating risks ▲ Compatible with heat-sensitive fabrics | Limited flexibility for low-temperature applications |

| Certifications | EU-regulated textile markets | Industry Standard: Basic EPR compliance (e.g., Germany) Our Base: EPR Germany Packing Our Advanced: EPR France Textiles + Packing ▲ | Full compliance with stringent EU regulations ▲ Streamlined export to France ▲ | Advanced version requires additional testing costs |

| Pattern Customization | Bespoke fashion/industrial projects | Industry Standard: Standard geometric patterns Our Base: Circular patterns Our Advanced: Customized patterns (ISO 3796) ▲ | Tailored solutions for niche applications ▲ Reduces waste in bespoke production | Advanced customization adds 2–3 days to lead time |

| Adhesive Strength | Lining for high-stress garments | Industry Standard: 10 N/cm² adhesion (ASTM D3330) Our Base: 15 N/cm² (PA coating) Our Advanced: 22 N/cm² (dual-layer adhesive) ▲ | Superior durability for heavy-use items like jackets ▲ Reduces delamination risks | Advanced adhesive requires specialized application tools |

| Softness | Luxury apparel/medical textiles | Industry Standard: Hand feel rating 4/10 (ASTM D7091) Our Base: 7/10 (ISO 13934-2) Our Advanced: 9/10 (ultra-fine weaving) ▲ | Ultra-soft texture for sensitive skin ▲ Enhances comfort in premium garments | Advanced version may require delicate handling during sewing |

⭐⭐⭐⭐⭐ Elena Martinez - Boutique Apparel Designer

"I've been using the Advanced Model for our spring collection, and it’s transformed how we construct structured blazers. The 30% elasticity allows for a tailored fit without sacrificing comfort, and the fusible PA coating bonds perfectly at 140°C—no bubbling or delamination. The EPR certification also makes it easier to export to EU clients with sustainability requirements."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Lin - Home Sewing Hobbyist

"As someone who makes custom jackets for fun, this interlining is a game-changer. I used the Base Model on a wool blend coat, and the soft hand feel and shrink-resistant properties made all the difference. It fused cleanly with my household iron—no need for industrial equipment. Plus, the 150cm width meant I could cover large panels without seams."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Sofia Petrova - Production Manager, Outerwear Factory

"We switched to the Pro Model for our high-performance outerwear line, and the results speak for themselves. With 65 N/cm tensile strength and 50% higher chemical resistance, it holds up through repeated washing and exposure to outdoor elements. The circular-knitted design also improves breathability in our active jackets. A solid upgrade from standard woven interlinings."Purchase Date: June 2024 | Usage Period: 1 year

⭐⭐⭐⭐☆ Amir Hassan - Upholstery & Curtain Artisan

"I ordered a custom 120cm width roll for curtain linings, and it worked beautifully. The adhesive is strong enough to bond to medium-weight fabrics without stiffness, and the breathable mesh helps reduce moisture buildup. Only reason I didn’t give 5 stars is that the fusing temp took some trial and error—I started too hot and warped a test swatch. Now that I’m at 135°C, flawless results."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Clara Bennett - Master Tailor

"This interlining has become my go-to for suit facings and collar stays. The polyester-spandex blend gives just enough stretch to move with the wearer, while still holding shape. I especially appreciate that it works equally well on both knits and wovens—something many fusibles fail at. And being EPR-compliant means I can confidently label my pieces as eco-conscious."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Lena Weber - Textile Innovation Consultant

"The integration of spandex into a fusible interlining matrix represents a significant advancement in adaptive garment technology. This product’s precise elasticity grading across models (20–40%) allows for application-specific optimization—something rarely seen in off-the-shelf interlinings. Its PA coating and ISO-certified construction place it ahead of industry norms in durability and environmental compliance."

Marie Dubois - Eco-Focused Fashion Label Founder

"In my search for sustainable yet functional interlinings, this one stands out. Not only does it meet EPR standards in France and Germany, but its performance eliminates the need for rework or reinforcement, reducing waste. The ability to customize hole patterns and widths also supports zero-waste cutting techniques. A responsible choice for modern designers."

Posted: 2 days ago

"Used the Advanced Model on a slim-fit stretch wool blazer. Held structure beautifully after dry cleaning. Clients love the comfort. Will reorder."

Posted: 1 week ago

"The softness and drape are ideal for lightweight jackets. No stiffness, no bubbling. And the EPR certification helps with our sustainability reporting."

Posted: 3 weeks ago

"Bought a small roll for my thesis collection. Easy to use with a home iron. Wish there was a sample pack option, but overall very impressed."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.