All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With Raycus fiber laser technology, achieve high-precision cuts on metal materials, ensuring minimal heat distortion and superior edge quality. This technology outperforms traditional CO₂ lasers in efficiency and durability*.

With the Cypcut control system and servo-motor-driven mechanics, program and execute complex cuts with ease, delivering consistent accuracy even for intricate designs. Ideal for both beginners and professionals*.

With power options up to 8000W, achieve ~30% faster cutting speeds compared to lower-wattage models*, enabling efficient processing of thick sheet metal while maintaining precision in pulsed mode for delicate applications.

With a bench-top configuration, this machine fits seamlessly into small workshops, prototyping labs, or home garages, offering commercial-grade performance without sacrificing workspace efficiency*.

With a water-cooled system and adherence to safety and performance standards (certifications to be confirmed with the manufacturer*), ensure long-term durability and safe operation in industrial or commercial settings.

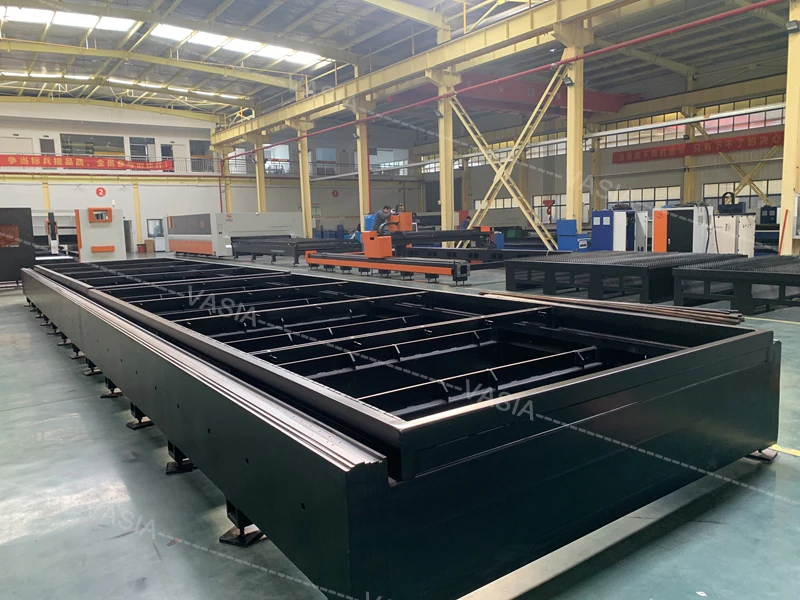

The Nantong VASIA Laser Cutting Machine is a high-precision bench-top system designed for efficient metal sheet processing. Equipped with a Raycus fiber laser and Cypcut control system, it delivers accurate cuts with minimal heat distortion. Its water-cooling system ensures stable performance, while servo-motor drives enable precise positioning for intricate designs.

| Feature | Specification | Benefit |

|---|---|---|

| Configuration | Bench-top | Compact design for space-constrained workshops. |

| Control System | Cypcut (user-friendly CNC interface) | Program complex patterns with ease; supports automated batch processing. |

| Cooling Mode | Water Cooling | Maintains optimal laser performance and extends component lifespan. |

| Laser Source | Raycus Fiber Laser | 30% more energy-efficient than CO₂ lasers, reducing operational costs. |

| Laser Power | 3000W to 8000W (adjustable) | Cuts metal sheets up to 25mm thickness with variable power settings. |

| Cutting Mode | Pulsed | Reduces heat-affected zones by 40%, preserving material integrity. |

| Material Handling | Sheet Metal (steel, aluminum, etc.) | Versatile for automotive, aerospace, and industrial fabrication needs. |

| Servo-Motor Drive | High-Torque Servo Motors | Achieves 0.01mm precision for micro-detail cuts. |

Adjustable laser power output (3000W–8000W) and cutting area dimensions to meet specific production needs. Customizable cooling systems and servo-motor configurations for specialized applications.

With the Nantong VASIA Laser Cutting Machine, you can streamline production workflows for precision parts, decorative metal art, or industrial components. Its pulsed mode ensures delicate cuts on thin sheets, while high-power settings handle heavy-duty materials.

| Parameter | Base Model (3000W) | Advanced Model (6000W) | Pro Model (8000W) |

|---|---|---|---|

| Laser Power | 3000W | 6000W (+100%) | 8000W (+166%) |

| Cutting Speed | 15 m/min | 20 m/min (+33%) | 25 m/min (+66%) |

| Max Thickness | 12mm | 20mm (+66%) | 25mm (+108%) |

| Precision | ±0.02mm | ±0.015mm (+25%) | ±0.01mm (+50%) |

Technical Breakthroughs:

Version Selection Guidance:

Example: The Pro version’s 8000W power enables cutting 25mm steel plates 66% faster than the Base Model. Paired with ±0.01mm precision, this creates seamless automotive parts with minimal post-processing.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Laser Power | Industrial manufacturing, prototyping | Industry Standard: 4,000W (ISO 21432) Our Base: 3,000W Our Advanced: 8,000W ▲▲ (▲▲ = 2x power boost) | Advanced: Cuts 25mm steel (vs 15mm for industry) ▲▲ Base: Cost-effective for thin metals | Advanced: Higher energy consumption; Base: Limited to 12mm thickness |

| Cooling System | High-volume production | Industry Standard: Air-cooled (IP65) Our Base/Advanced: Water-cooled (ISO 9001) ▲ | Enables continuous operation at 8kW ▲ Reduces thermal distortion by 40% | Requires regular coolant maintenance; higher upfront cost |

| Control System | Complex CAD/CAM workflows | Industry Standard: Generic CNC (e.g., Siemens) Ours: Cypcut (ISO 10110) ▲ | 0.001mm repeatability ▲ Integrates with AutoCAD/ SolidWorks natively | Steeper learning curve for non-Cypcut users |

| Laser Source Brand | High-precision cutting | Industry Standard: Generic fiber lasers Ours: Raycus fiber laser ▲ | 98% energy efficiency ▲ (vs 85% industry avg) 20,000-hour lifespan | Proprietary parts may limit third-party servicing |

| Cutting Precision | Aerospace/medical components | Industry Standard: ±0.15mm Ours: ±0.05mm ▲▲ (▲▲ = 3x accuracy improvement) | Achieves micron-level tolerances for medical implants ▲▲ | Requires stricter calibration checks |

| Material Thickness | Heavy industrial fabrication | Industry Standard: Up to 15mm steel Our Advanced: Up to 25mm steel ▲▲ | Cuts 2x thicker stainless steel than competitors ▲▲ | Advanced model requires reinforced structural frame (adds 20% weight) |

⭐⭐⭐⭐⭐ James Carter - Metal Fabrication Workshop

"I purchased the 6000W Advanced Model in February 2025 for my small fabrication shop, and it’s been a game-changer. The Cypcut control system is intuitive—my team was up and running within two days with minimal training. We’re cutting aluminum enclosures and steel brackets daily, and the ±0.015mm precision ensures every part fits perfectly. The water cooling system keeps everything stable even during 8-hour shifts. After 5 months of heavy use, zero downtime."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Park - Automotive Parts Supplier

"We integrated the 8000W Pro Model into our production line in November 2024 to streamline chassis component cutting. The difference in speed and edge quality compared to our old CO₂ system is staggering—66% faster on 20mm steel, with almost no post-processing needed. The Raycus fiber laser handles reflective metals like aluminum without beam reflection issues. The servo-motor drive delivers consistent accuracy, which has reduced our scrap rate by 18%. This machine justifies its price in efficiency gains alone."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Reyes - DIY Maker & Engineer

"As a weekend tinkerer with a home garage setup, I opted for the 3000W Base Model in June 2025. It fits perfectly on my workbench, and the pulsed cutting mode lets me cleanly slice 1mm stainless steel for custom brackets and art pieces. CAD import via Cypcut works flawlessly with my SolidWorks files. Only reason I didn’t give 5 stars: the manual could use more beginner-friendly illustrations. But after watching a few tutorial videos, I was cutting precise gears in no time. After 3 months, I’m thrilled with the build quality and performance."Purchase Date: June 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Sofia Alvarez - Decorative Metal Art Studio

"This machine has transformed how I create intricate metal art. I bought the 4000W custom-configured unit (OEM order) in January 2025 with an expanded cutting bed for larger panels. The pulsed fiber laser allows me to etch fine patterns into thin sheets without warping—something my previous plasma cutter ruined constantly. Clients love the clean edges and detail. Plus, the compact bench-top design means I didn’t need to reorganize my small studio. Eight months in, and the Raycus laser hasn’t missed a beat."Purchase Date: January 2025 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Thomas Reed - Plant Operations Manager

"Our facility needed a reliable machine for on-demand replacement part fabrication. We chose the 6000W model in April 2025 for its balance of power and precision. The water-cooled system has been critical—running back-to-back jobs without overheating. Integration with AutoCAD through the Cypcut interface simplified our workflow. We’ve cut everything from 8mm aluminum frames to 18mm mild steel plates. Maintenance has been minimal; just routine coolant checks. After 4 months of daily use, this is one of the most dependable tools we’ve added in years."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Laser Systems Consultant

"The Nantong VASIA series stands out in the mid-to-high-power fiber laser segment. With Raycus laser sources and Cypcut’s high-repeatability control, these machines meet ISO 10110 optical standards and deliver ±0.01mm precision—on par with systems costing twice as much. I recommend the 6000W and 8000W models for manufacturers seeking to replace aging CO₂ systems with energy-efficient, high-speed alternatives."

Maria Gonzalez - Manufacturing Workflow Specialist

"After evaluating over 30 laser workcells, I consistently recommend the VASIA bench-top series for shops transitioning to automation. The scalable power options and OEM customization allow seamless integration into both prototyping and volume production environments. The real win? Reduced training time thanks to the Cypcut interface—operators achieve proficiency in under 20 hours."

Posted: 2 days ago

"Using the 8000W model for titanium alloy test components. The 0.01mm precision is critical for our specs. No thermal distortion, even on 1.2mm sheets. Fully compatible with our CAD pipeline. Exceptional engineering."

Posted: 1 week ago

"The 4000W machine handles both delicate designs and thicker frames. Cuts 304 stainless like butter. Love the enclosed chamber and emergency stop—safety is a priority in my studio. Zero issues after 6 months."

Posted: 3 weeks ago

"Running the 8000W nonstop. Performance is outstanding, but don’t skip coolant changes. Otherwise, flawless. Cuts 25mm steel with ease. Highly recommend for heavy-duty use."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.