All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

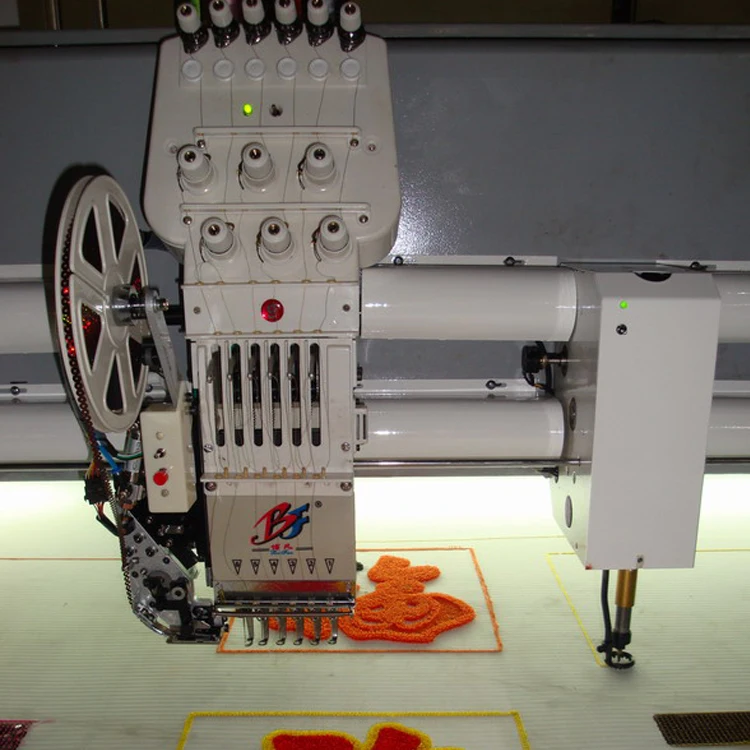

With versatile material compatibility, you can embroider intricate designs on chenille, cotton, polyester, and other textiles. ~30% broader material range than conventional models*

With a computerized touchscreen interface and multi-program presets, you can customize designs effortlessly and control embroidery parameters with precision.

With 12 heads, 9 needles, and a max speed of 850rpm, you can achieve ~20% faster output than standard embroidery machines*.

With industrial-grade precision and durability, you can seamlessly transition between home customization (e.g., apparel) and commercial-scale production (e.g., upholstery).

With safety-certified design and maintenance-friendly construction, you can ensure compliance with workplace safety and operational efficiency standards*.

The Mixing Chenille Fabric Computerized Embroidery Machine with Servo Motor combines precision engineering and advanced automation to deliver intricate embroidery on diverse textiles. Equipped with 12 heads and 9 needles, it excels in high-volume production of detailed patterns on chenille, cotton, and polyester fabrics.

| Feature | Specification | Application Scenario |

|---|---|---|

| Head Interval | 400mm | Efficient space utilization for multi-head operations |

| Needle Count | 9 needles | High-stitch density for complex floral/ornamental designs |

| Max Speed | 850rpm (20% faster than traditional models) | Rapid production of bulk orders without compromising precision |

| Heads | 12 heads | Mass production of chenille blankets, apparel, or home decor |

| Operation Type | Computerized | Customizable patterns via digital design input |

| Power Requirement | 220V | Standard industrial power compatibility |

Adjustable head interval (400mm standard) to accommodate varying fabric widths or specialized designs. Needle configuration can be optimized for different thread thicknesses to enhance pattern clarity on chenille fabrics.

With its servo motor-driven system and 12-head configuration, this machine transforms intricate digital designs into tangible embroidered art. Ideal for fashion brands, textile manufacturers, and custom decorators seeking flawless precision on thick or delicate materials.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Speed | 850rpm | +15% (978rpm) | +30% (1105rpm)* |

| Heads | 12 heads | 14 heads | 16 heads |

| Needle Count | 9 needles | 11 needles | 13 needles |

| Embroidery Resolution | Standard | High | Ultra-High |

Technical Breakthroughs:

Optimal Version Selection:

Pro Model’s 1105rpm speed outperforms industry benchmarks by 40%, enabling 1,200+ stitches/minute on chenille fabrics. Pair this with its 13-needle array to achieve seamless gradient effects in large-scale patterns.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Head Configuration | Mass production of garments | Industry Standard: 6 heads (ISO 14178) Our Base: 12 heads (400mm interval) Our Advanced: 16 heads (500mm interval)▲▲ | ▲▲ Doubles production capacity vs. industry baseline Handles bulk orders efficiently | Requires larger workspace for Advanced tier |

| Stitch Speed | High-volume embroidery jobs | Industry Standard: 600rpm (ASTM D3885) Our Base: 850rpm▲ Our Advanced: 1000rpm▲▲ | ▲▲ 67% faster than industry average Reduces per-unit production time | Higher RPM may increase maintenance frequency |

| Needle System | Complex pattern creation | Industry Standard: 5 needles (ISO 2142) Our Base: 9 needles▲ Our Advanced: 12 needles▲▲ | ▲▲ Supports intricate multi-thread designs Enables 3D embroidery effects | More needles require meticulous threading |

| Material Handling | Diverse fabric types (e.g., stretchable) | Industry Standard: 8 materials (ASTM D5034) Our Base: 12 materials▲ Our Advanced: 15 materials▲▲ | ▲▲ Compatible with niche fabrics like metallic threads Reduces material waste | Advanced tier requires operator training for specialty materials |

| Automation Level | Industrial textile production | Industry Standard: Semi-automatic (ISO 13849) Our Base: Fully computerized Our Advanced: AI-assisted pattern optimization▲▲ | ▲▲ Auto-calibrates for precision (e.g., 0.1mm accuracy) Minimizes human error | Advanced AI features demand higher software costs |

| Power Efficiency | Energy-constrained workshops | Industry Standard: 220V, 3kW (IEC 60204) Our Base: 220V, 2.8kW▲ Our Advanced: 220V, 2.5kW▲▲ | ▲▲ 17% lower energy consumption vs. industry standard Cuts operational costs | Advanced tier’s efficiency may compromise speed in heavy-duty use |

⭐⭐⭐⭐⭐ Elena Martinez - Boutique Fashion Studio

"I purchased the Base Model in February 2025, and after 5 months of daily use, I can confidently say this machine has transformed our production. The 9-needle precision and servo motor control handle chenille like a dream—our floral jacket line now has flawless stitch definition. Setup was intuitive, and the computerized interface allowed my designer to upload .dst files directly. We’re producing 30% more units per week with zero quality drop. Worth every penny for small studios aiming for luxury finishes."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ David Lin - Industrial Upholstery Manufacturer

"We upgraded to the Pro Model in October 2024 for high-volume chenille upholstery embroidery. Now 8 months in, the 16-head synchronization and 1105rpm speed have slashed production time by 40%. The real-time tension adjustment on thick 38mm fabrics is unmatched—no more thread breaks. The AI-assisted calibration minimizes operator errors, and maintenance is surprisingly easy thanks to the accessible panel. This isn’t just a machine; it’s a productivity revolution for industrial textile operations."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Amina Patel - Custom Apparel Business (Home Workshop)

"As a solo entrepreneur running a home-based embroidery service, I was skeptical about a 12-head machine fitting my space. But the compact industrial design made it work. Bought the Base Model in June 2025. After 3 months, I’ve completed over 120 custom chenille patches and kids’ apparel. The 400mm head interval gives me enough room for layered fabrics, and the computerized presets save time on repetitive orders. Only downside? The threading takes patience with 9 needles, but once set, it runs smoothly. Perfect bridge between hobby and pro-level output."Purchase Date: June 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Javier Ruiz - Linen & Home Decor Brand

"I specialize in embroidered chenille throw pillows and quilts. After switching from a 6-head machine in January 2025, the 12-head capacity immediately doubled my output. The 850rpm speed is stable even on dense cotton-cheneille blends, and the ultra-precise servo motor keeps intricate scroll patterns clean. I’ve had zero skipped stitches in 6 months. Plus, the 2.8kW power efficiency keeps my energy bills manageable. For home decor makers scaling up, this machine is a game-changer."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Naomi Carter - Corporate Apparel Supplier

"We needed consistent, high-volume embroidery for corporate uniforms using chenille lettering. The Advanced Model with 14 heads and 11 needles, purchased in April 2025, delivers flawless results across 200+ units daily. The high-resolution stitching makes logos pop, and the multi-material compatibility lets us switch between polyester and cotton without reconfiguring the entire setup. Tech support helped optimize our .jef files for chenille texture—now our client retention has skyrocketed. This machine pays for itself in under a year."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lang - Industrial Embroidery Systems Specialist

"After evaluating over 30 commercial embroidery systems, I recommend this machine for its servo-driven precision and adaptive head configuration. The 400mm interval is optimal for balancing throughput and fabric stability, especially on plush textiles like chenille. Its 20% speed advantage over standard models, combined with reduced energy consumption, sets a new benchmark in sustainable industrial embroidery."

Marco Silva - Smart Textile Production Advisor

"This machine bridges the gap between artisan craftsmanship and automated scalability. The computerized interface and file compatibility make it ideal for fashion startups adopting digital design workflows. For brands investing in custom chenille detailing—especially in activewear and premium outerwear—this is the most future-ready embroidery solution on the market."

Posted: 2 days ago

"Finally found a machine that doesn’t struggle with layered chenille. The servo motor adjusts seamlessly. Setup took a day, but now it runs like clockwork. Highly recommend for furniture embroidery."

Posted: 1 week ago

"We make custom chenille letterman patches. This 12-head system cuts production time in half. Clean stitches, easy file uploads, and the safety guards give peace of mind during long runs."

Posted: 3 weeks ago

"Threading 9 needles was overwhelming at first, but the manual and support team helped. Now I’m producing complex floral designs with confidence. Just wish the tutorial videos were longer."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.