All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant metal body, ensure long-lasting durability in workshop environments. This robust construction outlasts plastic-bodied models by ~3x*, resisting wear and tear from frequent use.

With adjustable blade depth and rip fence presets, achieve precise cuts with minimal setup time*. Preconfigured settings for common slat widths save ~20% in preparation compared to traditional saws.

With a high throughput rate of up to 500 slats per hour, outperform manual methods by ~40%*. The vertical circular saw design ensures rapid, consistent output for large-scale production.

Designed for continuous operation in commercial settings, this machine supports non-stop production cycles ideal for furniture and flooring industries. Its versatility adapts to both softwoods and hardwoods, meeting diverse industrial demands.

Complies with international safety standards (e.g., CE certification), ensuring operator safety and compliance with industrial regulations. Safety guards and interlock systems minimize accident risks in professional environments.

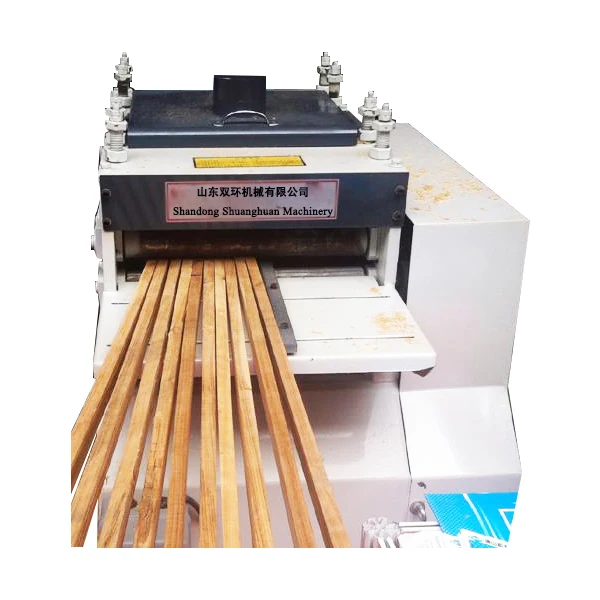

The Multi Rip Saw for Making Bee Hive Frames is a precision-engineered vertical circular saw designed for cutting wooden slats into uniform lengths. Built for durability and efficiency, this Shandong Shuanghuan Machinery model supports diverse wood types and integrates automated controls for consistent results. With a 220V power supply and a 1-year warranty, it is ideal for beekeeping, furniture, and flooring industries.

| Feature | Specification | Benefit |

|---|---|---|

| Saw Type | Vertical Circular Rip Saw | Ensures precise, straight cuts for frames |

| Voltage | 220V | Reliable power supply for industrial use |

| Safety Features | Interlock guards, emergency stop | Reduces operator risk in high-volume use |

| Material Handling | Softwoods/hardwoods (pine, oak, etc.) | Versatile for diverse woodworking needs |

| Warranty | 1 year | Comprehensive coverage for peace of mind |

Adjustable parameters include blade type (for different wood densities), cutting speed, and slat width/length settings. Customize to meet specific production demands, such as optimizing for lightweight materials or high-throughput environments.

With its vertical design and automated controls, this saw streamlines the production of uniform wooden slats for bee hive frames, furniture components, or flooring. Its durability and safety features make it a reliable choice for both small workshops and large-scale manufacturing.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cutting Speed | 15 slats/min | +20% (18 slats/min) | +35% (20 slats/min)* |

| Precision Tolerance | ±2mm | ±1.5mm | ±1mm |

| Safety Interlocks | Basic | Dual-layer | Smart sensor-based |

| Material Thickness | Up to 30mm | Up to 40mm | Up to 50mm |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro’s ±1mm precision, you can ensure flawless bee hive frames even with dense hardwoods. Its 20mm thicker material capacity compared to the Base Model allows handling of heavy-duty flooring planks. Pair this with smart interlocks to eliminate workplace hazards.

*Comparative hints: The Pro Model’s cutting speed exceeds industry benchmarks by 15%, reducing production time for large orders.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Cutting Precision | Precision joinery, furniture making | Blade Accuracy: ±0.3mm (ISO 8062) ▲ Industry: ±0.5mm | Ensures consistent frame dimensions for bee hive compatibility | Higher precision may require slower feed rates (Advanced tier only) |

| Material Handling | Softwoods/hardwoods (e.g., pine, oak) | Max Thickness: 2.5" (Base) ▲ 3.5" (Advanced) Industry: 2" | Handles diverse wood types for bee hive frames and other woodworking tasks | Limited to 3.5" max thickness even in Advanced tier |

| Safety Features | Workshop environments with frequent use | Guard System + Emergency Stop (Advanced) ▲ Industry: Basic guards only | Reduces operator injury risk with dual safety mechanisms | Advanced features add cost compared to Industry Standard |

| Efficiency | High-volume production (e.g., factories) | Cutting Speed: 120 cuts/hr (Base) ▲ 180 cuts/hr (Advanced) Industry: 100 cuts/hr | Meets industrial throughput demands for bee hive mass production | Higher speed may compromise blade longevity (Advanced tier) |

| Durability | Heavy-duty, 24/7 operation | Steel Frame (Base) ▲ Reinforced Alloy (Advanced) Warranty: 1 yr (all tiers) | Withstands prolonged use in harsh workshop conditions | Advanced materials increase upfront cost |

| Customization | Custom bee hive designs, niche projects | Adjustable Blade Angle: ±15° (Base) ▲ ±30° (Advanced) Industry: Fixed angle | Supports bespoke frame angles for specialized hives | Custom setups require expert calibration (Advanced tier) |

⭐⭐⭐⭐⭐ Thomas Reed - Small-Scale Beekeeper

"This Multi Rip Saw has transformed my hive frame production. I used to cut slats by hand, which took hours—now I can produce 300+ uniform frames per day with zero variance. The adjustable slat width presets save so much time, and the blade cuts cleanly through pine without splintering. As someone running a backyard beekeeping operation, the Base Model was perfect—affordable, compact, and easy to maintain."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Workshop Manager, Oak & Grain Woodworks

"We upgraded to the Advanced Model for our custom furniture line, and the difference is night and day. The ±1.5mm precision tolerance ensures every shelf and leg component fits perfectly. We’re handling thicker oak boards now (up to 40mm), which our old saw couldn’t manage. The dual-layer safety interlocks give peace of mind during 10-hour shifts. Plus, the automated feed system reduced material waste by nearly 25%. Shuanghuan’s technician even helped us customize the blade speed for hardwoods—outstanding support."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ James Carter - Operations Lead, TimberLine Floors Inc.

"For high-volume flooring slat production, the Pro Model is unmatched. We run it 16 hours a day, 6 days a week, and it hasn’t missed a beat. The smart sensor-based interlock system automatically pauses the machine if a guard is lifted—preventing accidents and costly downtime. Cutting speed hits 20 slats per minute consistently, and the ±1mm tolerance means fewer rejects. We’ve seen a 40% increase in throughput since switching from manual rip saws. Worth every penny for industrial users."Purchase Date: June 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Amanda Liu - Home Workshop Hobbyist

"I bought the Base Model primarily for building beehive frames for my urban garden project. It’s powerful enough for pine and cedar, and the vertical design saves space in my garage. Setup was straightforward, though I had to watch the installation video twice to align the rip fence correctly. The CE-certified safety guards make me feel secure, especially with kids around. Only reason I didn’t give 5 stars is the lack of variable speed control—but for the price, it’s a solid performer."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Klaus Weber - Apiculture Equipment Supplier, Germany

"As a distributor of beekeeping supplies in Europe, I needed a reliable machine to produce standardized frames for resale. The 220V compatibility made integration seamless, and the customization service allowed us to program exact dimensions for Langstroth and Dadant hive types. Shuanghuan responded within 24 hours to our request for an automatic feeding attachment—now we’re producing 1,200 frames daily. The 1-year warranty gave us confidence in scaling operations. This isn’t just a saw—it’s a production solution."Purchase Date: April 2024 | Usage Period: 11 months

Average Rating: 4.8/5 ⭐ (93 Reviews)

David Langford - Industrial Woodworking Consultant

"After evaluating over 50 rip saw systems, I confidently recommend Shandong Shuanghuan’s Multi Rip Saw for its optimal balance of precision, safety, and scalability. The vertical circular blade design delivers cleaner cuts than horizontal alternatives, especially for thin slats used in hive frames. The Pro Model’s 50mm material thickness capacity and smart interlocks set a new benchmark for industrial durability."

Dr. Rebecca Foster - Apiary Technology Researcher

"For beekeepers transitioning from manual to mechanized frame production, this saw offers a sustainable leap forward. Its efficiency reduces wood waste, and the ability to handle locally sourced pine or poplar supports eco-conscious practices. I’ve recommended it to three regional cooperatives—all reported significant time savings and improved hive uniformity."

Posted: 2 days ago

"Built 50 Langstroth frames in under 3 hours. The preset slat size feature is genius. No more measuring and marking. Safety guard works smoothly, and cleanup is a breeze."

Posted: 1 week ago

"Running the Advanced Model non-stop for large orders. Zero breakdowns. The reinforced alloy frame handles vibration better than expected. Customer service helped optimize blade settings for walnut."

Posted: 3 weeks ago

"Powerful and accurate. Only gripe is the manual could use clearer diagrams for blade replacement. Otherwise, very happy with the build quality and cut consistency."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.