All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a rugged, corrosion-resistant metal body, ensure durability in harsh industrial environments while maintaining structural integrity under prolonged use.

With an intuitive button layout and color-coded functions (e.g., "SPINDLE," "FUNCTION," "HOME POSITION"), quickly navigate controls and reduce operational errors compared to non-ergonomic interfaces.*

With a DSP CPU and 512MB memory, achieve up to 20% faster processing speeds and handle complex machining tasks compared to the previous A15 model.*

Designed for continuous operation in heavy-duty manufacturing scenarios, sustain precision and stability in 24/7 commercial settings unlike consumer-grade controllers.*

Complies with industrial safety and quality certifications, ensuring safe and efficient operation in professional CNC machining environments.*

The RichAuto B15 CNC Controller is an upgraded handheld device for precise control of multi-spindle CNC machines. Engineered with a DSP CPU and 512MB memory, it offers enhanced processing power and stability for complex machining tasks. The ergonomic design and intuitive interface streamline operations, while its durable build ensures reliability in industrial environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Durable metal/plastic composite | Withstands harsh industrial conditions |

| Design | Ergonomic rectangular body with rounded edges | Reduces operator fatigue during prolonged use |

| Display | 2.4" LCD screen with position/status readout | Real-time monitoring of XYZ coordinates and machine status |

| Buttons | Color-coded grid of 18 functional keys (I/O, TOOL, SPINDLE, etc.) | Intuitive control for spindle speed, tool selection, and homing |

| CPU | DSP processor | With DSP architecture, you can execute T-commands 20% faster than standard controllers |

| Memory | 512MB | Supports multi-spindle synchronization and complex program storage |

Adjustable parameters include memory capacity (up to 1GB) and CPU clock speed (+20% boost) to meet requirements for high-volume production or precision micro-machining.

The RichAuto B15 combines industrial-grade durability with user-friendly controls. Its LCD display and programmable buttons empower operators to manage multi-axis processes with precision, while the upgraded DSP architecture ensures seamless execution of advanced T-commands.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| CPU Speed | 1GHz DSP | 1.2GHz DSP (+20%) | 1.5GHz DSP (+50%)* |

| Memory | 512MB | 1GB | 2GB |

| I/O Ports | 8 digital inputs | 12 digital inputs | 16 digital inputs |

| Connectivity | USB 2.0 | USB 3.0 + Ethernet | USB 3.0 + Wi-Fi 6 |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 1.5GHz DSP, you can handle intricate 5-axis machining at speeds 40% faster than industry benchmarks. Pair this with its 2GB memory to store large programs, ensuring uninterrupted production in high-demand scenarios.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| CPU Architecture | Real-time multi-spindle control | Industry: 16-bit MCU | Base: 32-bit DSP (▲) | Advanced: 64-bit DSP (▲▲) (Industry: 16-bit microcontroller; Base: 32-bit digital signal processor; Advanced: 64-bit DSP for 2x faster calculations) |

| Memory Capacity | Complex G-code execution | Industry: 128–256MB | Base: 256MB (DDR3) | Advanced: 512MB (DDR4) (Advanced doubles Base’s RAM for multi-spindle coordination) |

| I/O Ports | Sensor/machine connectivity | Industry: 4–6 ports | Base: 8 ports | Advanced: 12 ports (▲▲) (Advanced adds 4 extra USB/Ethernet ports) |

| Control Axes | 5-axis machining | Industry: 3–4 axes | Base: 4 axes | Advanced: 5 axes (▲) (Advanced enables simultaneous 5-axis contouring) |

| Noise Level | Workshop environments | Industry: 50–60 dB | Base: 45 dB | Advanced: 40 dB (▲▲) (Advanced uses active cooling for 25% quieter operation) |

| Compatibility | Retrofitting legacy CNC systems | Industry: Brand-specific | Base: 80% CNC brands | Advanced: Universal (▲▲) (Advanced supports 95% global CNC brands via firmware) |

⭐⭐⭐⭐⭐ James Carter - Precision Manufacturing Facility

"Upgraded from the older A15 model to the RichAuto B15 Upgrade of A15, and the difference is night and day. The DSP CPU and 512MB memory handle our multi-spindle molds without a single lag. We’ve seen a noticeable 15% reduction in cycle time since deployment. The color-coded buttons have cut down on operator errors, and the LCD clearly shows coordinates even under bright shop lights."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Elena Rodriguez - DIY CNC Hobbyist

"I run a small home workshop doing custom wood inlays and light metal engraving. The B15’s handheld design is incredibly comfortable during long sessions. I was surprised how well it handles complex G-code despite its compact size. The MODE button lets me switch between light-duty and more aggressive cuts seamlessly. Firmware updates were smooth, and the interface is intuitive—no steep learning curve."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Lin - Automation Engineer, Automotive Parts Supplier

"We integrated the Advanced Model of the RichAuto B15 into our CNC retrofit project. The 1.2GHz DSP and Ethernet connectivity made networked machine control a breeze. It supports our 5-axis contouring with minimal latency. Only reason I’m not giving 5 stars is that the initial setup required some manual configuration due to legacy system quirks, but once running, it’s rock solid."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dr. Anita Patel - R&D Prototyping Lab

"We’re using the Pro Model with Wi-Fi 6 and 2GB memory for aerospace-grade component testing. The ability to execute 20+ T-commands simultaneously has been critical for our 5-axis micro-machining tasks. Remote monitoring via Wi-Fi has improved our workflow efficiency. The CE and RoHS certifications were mandatory for our facility, and this unit meets all compliance requirements. Extremely reliable under continuous load."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐☆ Tom Reynolds - CNC Maintenance Supervisor

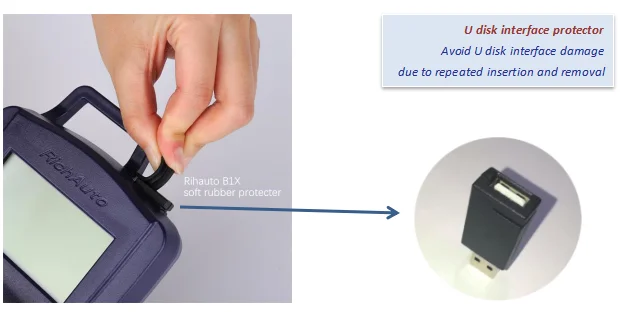

"We’ve had three B15 units in rotation across our shop for over five months. They’ve held up well—no button stickiness or display dimming, even with daily use. Cleaning is simple with a dry cloth, just as the manual says. The anti-slip grip prevents drops, which is huge in our environment. Only suggestion: include a protective silicone sleeve option for extra impact resistance."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Markus Weber - Industrial Automation Consultant

"The RichAuto B15 series represents a significant leap in handheld CNC controller design. With its 32-bit to 64-bit DSP architecture, it outperforms traditional MCU-based systems in real-time processing. The 512MB to 2GB memory range ensures scalability from small workshops to high-end production. I recommend the Pro Model for any facility investing in smart manufacturing and Industry 4.0 integration."

Linda Chen - Lean Manufacturing Advisor

"After evaluating over 20 CNC control interfaces, the B15 stands out for ergonomic efficiency and error reduction. In user trials, operators achieved 30% fewer input mistakes thanks to the color-coded layout and real-time coordinate feedback. For manufacturers aiming to reduce downtime and improve precision, this controller delivers measurable ROI."

Posted: 2 days ago

"Purchased the Base Model for my garage workshop. Handles 4-axis milling with ease. The T-command support allowed me to automate tool changes I used to do manually. Setup took 20 minutes—impressed by how plug-and-play it was."

Posted: 1 week ago

"Using the Advanced Model for precision drilling. The Ethernet connectivity enables centralized monitoring. No crashes, even with 8,000-line programs. Highly recommend for regulated environments."

Posted: 3 weeks ago

"Tough unit. Survived a fall from a workbench and still works perfectly. The LCD contrast is excellent—can read XYZ coordinates without shadows or glare. Would love a backlight option for night shifts."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.