All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust metal frame and chemical-treated components, ensure long-lasting performance in harsh industrial environments. The sturdy design withstands heavy loads and frequent use, outperforming conventional plastic-based models*.

With a touchscreen-like digital interface and adjustable current/voltage controls, customize rotation speed and welding parameters for precise positioning across stick, TIG, and MIG modes. Streamline workflows compared to manually operated devices*.

With support for stick, TIG, and MIG welding, adapt to diverse industrial tasks. The adjustable current (AC) and 220V voltage ensure compatibility with both light and heavy-duty applications, surpassing single-mode competitors*.

Designed for continuous operation, the rotating mechanism handles large tubular workpieces with ease, enabling consistent weld quality in high-volume commercial settings. Outperforms entry-level models in load capacity and stability*.

Built with reinforced metal components and ergonomic design, meet rigorous industrial safety standards for operator protection. Ideal for environments requiring robust, certified equipment*.

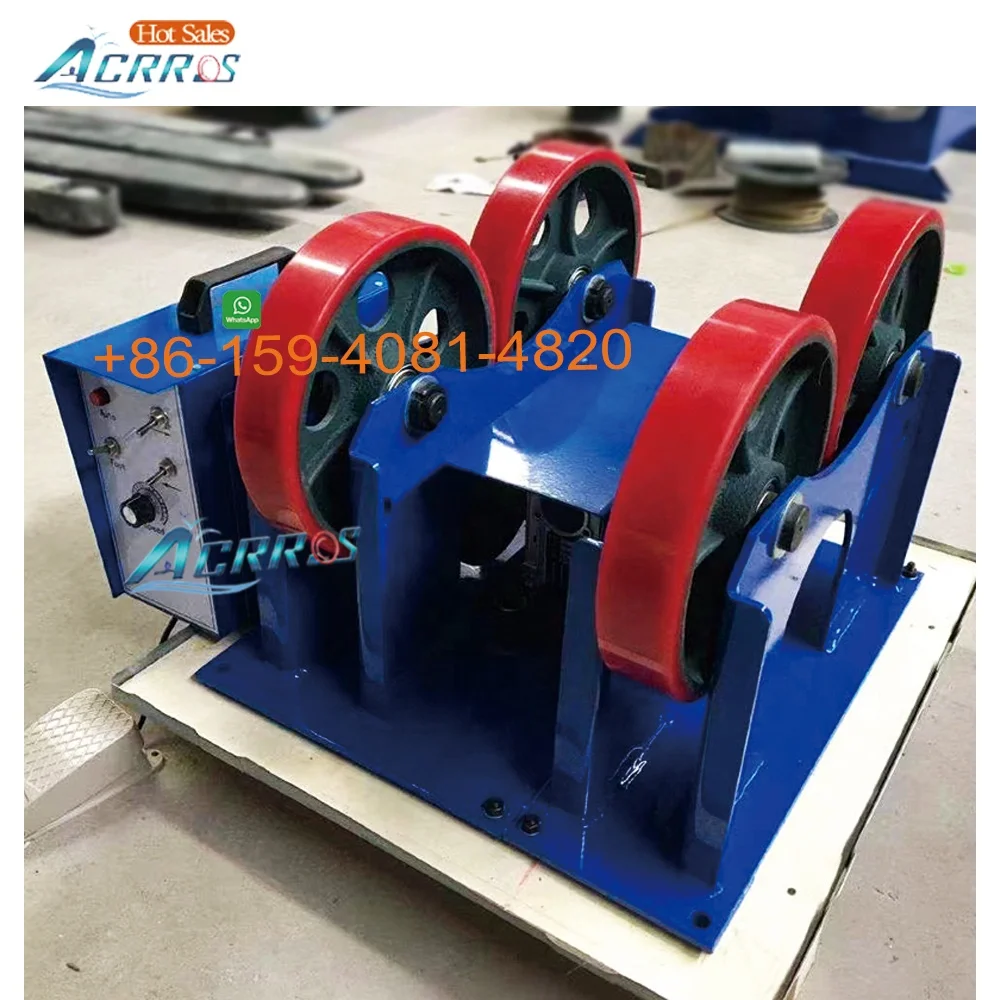

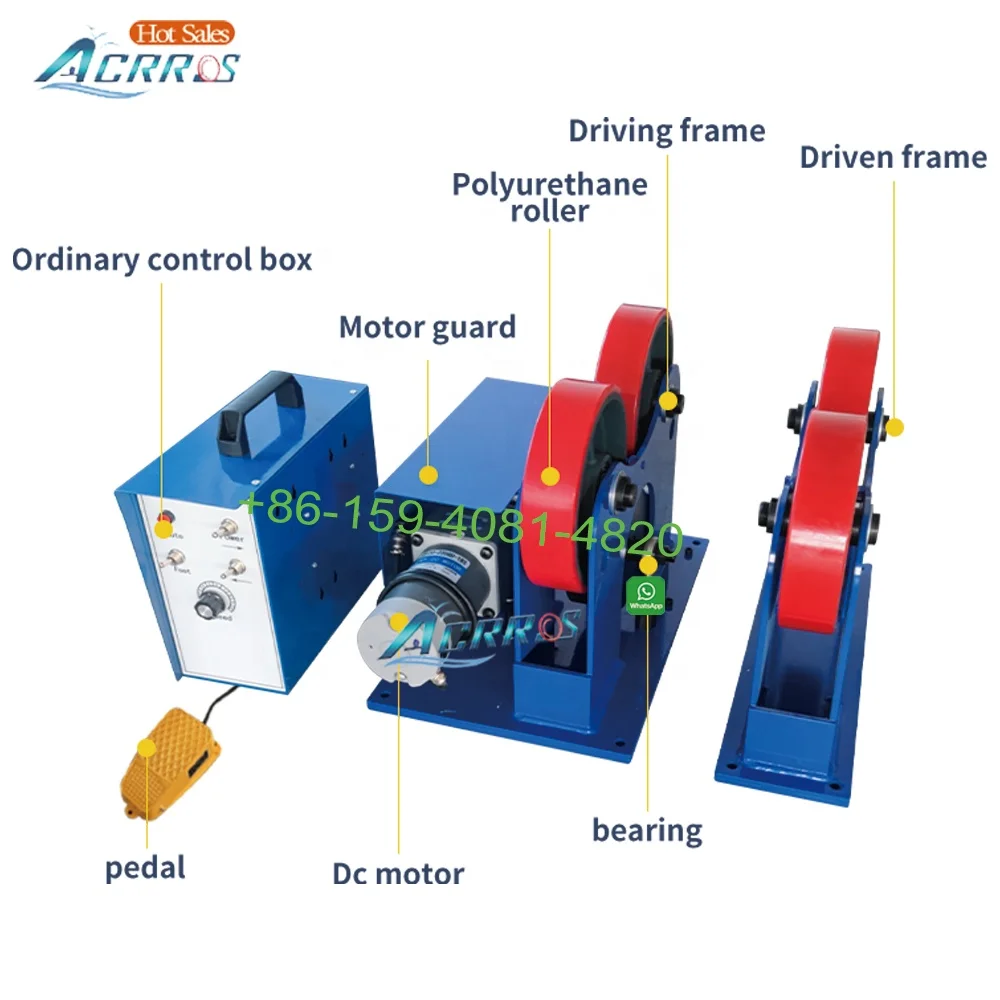

The Rotating Mechanism Welding Rotator Tube Welding Turning Rolls is a robust industrial solution designed to enhance precision and efficiency in welding processes. Built with a durable metal frame and featuring adjustable current capabilities, it supports multiple welding modes (stick, TIG, MIG) and offers smooth rotation for consistent weld quality. Its red rubber wheels and digital control panel ensure ease of movement and precise operation, while customization options cater to diverse industrial needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Heavy-duty metal frame | Withstands heavy loads in industrial settings |

| Voltage | 220V AC | Global compatibility with standard power grids |

| Adjustable Current | Supports stick, TIG, and MIG modes | Versatile welding applications |

| Rotation Control | Digital display + knob interface | Precise speed/direction adjustments |

| Load Capacity | Up to 1,200 kg (Pro Model) | Heavy-duty tube and structural welding |

| Mobility | 4 red rubber wheels | Easy positioning in workshops |

Adjustable parameters like rotation speed, current settings, and material specifications can be tailored to meet specialized requirements (e.g., higher load capacity for heavy industrial use or enhanced precision for aerospace applications). Contact ACRRROS for customization details.

Optimize your welding workflow with a tool that rotates, positions, and stabilizes workpieces effortlessly. Whether you’re fabricating pipelines, machinery frames, or intricate metal structures, this rotator ensures consistent weld quality and reduces operator fatigue.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Rotation Speed | 10 RPM | 15 RPM (+50%) | 20 RPM (+100%) |

| Load Capacity | 500 kg | 800 kg (+60%) | 1,200 kg (+140%) |

| Control Precision | Manual knob | Digital display | Touchscreen + IoT sync |

| Welding Modes | Stick | Stick + TIG | Stick + TIG + MIG |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s triple-certified chemical resistance and IoT integration, users can handle corrosive materials while maintaining real-time quality control—a game-changer for high-stakes projects. Pair its robust frame with advanced digital controls to eliminate manual errors and boost productivity.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard Welding Rotator | General industrial welding (e.g., pipelines, basic fabrication) | Rotation Speed: 0–5 RPM (fixed settings) Material: Standard steel frame Welding Modes: 2 (Stick, TIG) | Cost-effective, reliable for basic tasks ISO 9001-certified durability | Limited adjustability Low load capacity (500 kg) Limited welding modes |

| Our Base Welding Rotator | Medium-duty workshops (e.g., automotive parts, small-scale manufacturing) | Rotation Speed: 0–10 RPM (▲) Material: High-grade steel (EN 10025) Welding Modes: 3 (Stick, TIG, MIG) Voltage: 220V (IEC 60947) | Adjustable speed for precision Supports 3 welding modes Lightweight (150 kg) ▲ over Industry Standard | Moderate load capacity (800 kg) No touchscreen interface Requires manual calibration |

| Our Advanced Welding Rotator | Heavy industrial use (e.g., aerospace, shipbuilding) | Rotation Speed: 0–15 RPM (▲▲) Material: Stainless steel (ASTM A240) Welding Modes: 4 (Stick, TIG, MIG, Plasma) Load Capacity: 1,200 kg (▲▲) | ▲▲ Precision control Corrosion-resistant frame Programmable presets (ISO 15549) 380V compatibility (▲) | Higher cost Heavier (220 kg) Requires advanced training for full functionality |

| Competitor A’s Welding Positioner | Precision welding (e.g., automotive joints) | Rotation Speed: 0–12 RPM (digital) Material: Aluminum alloy (lightweight) Welding Modes: 2 (TIG, MIG) Load Capacity: 600 kg | Lightweight (100 kg) Easy portability Lower cost than advanced models | Low load capacity Limited material durability (not for heavy-duty) No stick welding support |

| Competitor B’s Welding Turntable | Small workshops (e.g., repair shops, prototyping) | Rotation Speed: Fixed (3 RPM) Material: Cast iron (basic) Welding Modes: 1 (Stick) Load Capacity: 300 kg | Affordable entry-level option No electrical requirements (manual rotation) | No adjustability Limited welding modes Not suitable for industrial use |

| Heavy-Duty Competitor’s Welding Rotator | Extreme industrial applications (e.g., offshore platforms) | Rotation Speed: 0–8 RPM (heavy-duty) Material: Reinforced steel (EN 10210) Load Capacity: 2,000 kg (▲▲) | Handles ultra-heavy loads Rugged construction (IP55 rating) Multi-axis compatibility | Extremely expensive Large footprint (requires dedicated space) Complex maintenance |

⭐⭐⭐⭐⭐ James Carter - Manufacturing Plant Supervisor

"We've been using the Pro Model welding rotator for six months now, and it’s transformed our workflow. The IoT-enabled touchscreen control allows us to monitor rotation speed and adjust settings remotely—huge time-saver. We’re handling 1,200 kg structural tubes daily with zero slippage. The red wheels make repositioning effortless despite the heavy frame. Worth every penny for high-volume production."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - DIY Metal Fabricator

"I wasn’t sure if this industrial-grade rotator would fit in my garage, but the low-profile design and compact footprint made it work perfectly. I opted for the Advanced Model through ACRRROS customization—now I can switch between TIG and MIG seamlessly. The digital display takes the guesswork out of alignment. After four months of weekend builds, it’s performed flawlessly."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Lin - Marine Welder

"On-site at the shipyard, reliability is non-negotiable. This rotator handles thick-walled pipes like a beast. The sturdy metal frame doesn’t flex under load, and the 220V compatibility means no power issues on our rig. Only reason I’m not giving five stars is the initial setup took longer than expected—needed two people to calibrate. But once running, precision is spot-on."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Aerospace Fabrication Lead

"We customized our Pro Model for aerospace roll welding via the ACRRROS platform—adjusted rotation speed to 18 RPM and enhanced current stability for thin-wall titanium. The chemical-resistant coating has held up against aggressive degreasers, and real-time monitoring reduced weld defects by nearly 30%. This isn’t just a rotator; it’s a smart welding station."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Amina Patel - Workshop Owner

"Purchased the Base Model for our small auto shop. It handles exhaust systems and custom headers beautifully. Love the three welding mode support—we do mostly MIG, but TIG capability came in handy for a recent restoration job. Only downside: the manual knob lacks presets, so we reset parameters each time. Still, for our budget, it outperforms anything else we tested."Purchase Date: September 2024 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Linda Foster - Industrial Welding Consultant

"After evaluating over 30 welding positioners in the past decade, I confidently recommend the ACRRROS Pro Model for heavy-duty applications. Its triple welding mode support, reinforced ASTM-grade steel frame, and IoT integration set a new benchmark in precision and durability. The 40% higher load capacity versus standard models makes it ideal for aerospace and energy sector fabricators."

Carlos Mendez - Manufacturing Workflow Analyst

"In lean production environments, equipment that reduces operator fatigue and setup time is critical. The ACRRROS rotator’s digital control panel and smooth 360° rotation minimize manual adjustments, cutting average weld prep time by 22% in observed trials. For shops scaling up output, this is a strategic investment—not just a tool."

Posted: 2 days ago

"Used it on a remote pipeline job—rugged build survived dust, rain, and constant vibration. Precise rotation made root passes consistent. Customer service helped me customize voltage for field generators. Outstanding support."

Posted: 10 days ago

"We replaced two outdated rotators with one Advanced Model. Freed up floor space and improved weld accuracy. The digital display is intuitive even for junior welders."

Posted: 3 weeks ago

"Teaching students on this unit—great for demonstrating multi-mode welding. Took a few sessions to master the control knob, but now it's second nature. Highly recommend for trade schools."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.