All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body constructed from stainless steel and aluminum, you can ensure long-lasting durability in harsh industrial environments compared to plastic-bodied alternatives*.

With an intuitive digital control panel and programmable presets, you can streamline setup and operation more efficiently than manual systems*, reducing downtime and improving workflow.

With adjustable power outputs from 100W to 3000W and a water-cooled system, you can achieve precise welding across diverse materials while maintaining continuous operation longer than air-cooled models*.

With rust removal and precision welding capabilities, you can tackle both maintenance tasks (e.g., cleaning corroded surfaces) and high-precision manufacturing scenarios, offering broader application versatility than single-purpose devices*.

With CE and EPR Germany certifications, you can meet stringent safety and environmental regulations, exceeding basic compliance standards in industrial applications*.

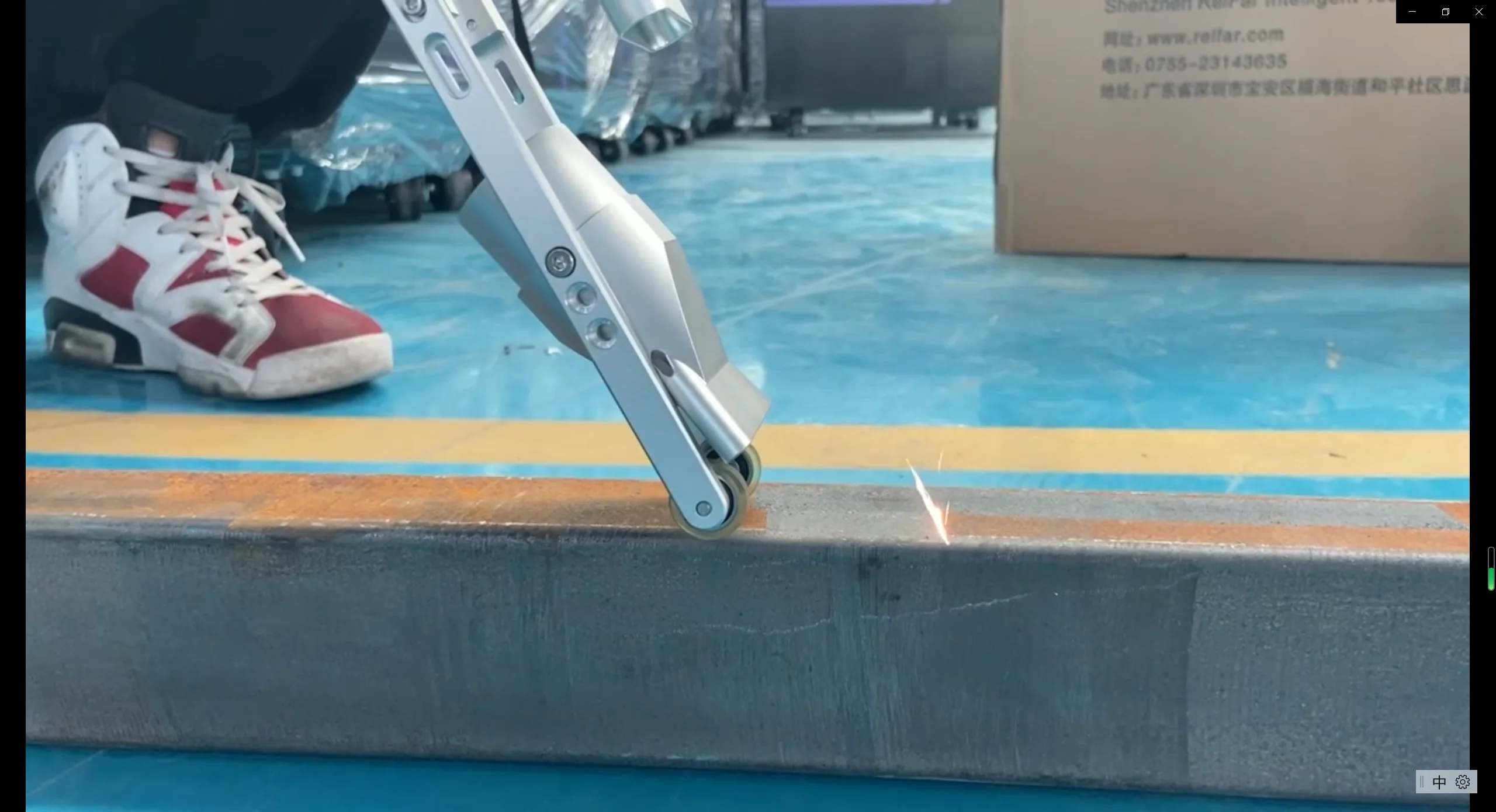

The AccTek AKQ-1000 Rust Laser Remover Machine is a high-precision industrial tool designed for efficient rust and surface cleaning across metals, stainless steel, aluminum, and carbon steel. Equipped with fiber laser technology and water-cooling systems, it ensures minimal thermal distortion and maximum material integrity. Certified to CE and EPR Germany Packing standards, this compact machine combines robust construction with user-friendly automation for diverse industrial applications.

| Feature | Specification | Benefit |

|---|---|---|

| Laser Type | Fiber Laser | High precision, low heat input, no consumables |

| Material Compatibility | Metal, Stainless Steel, Aluminum, Carbon Steel | Versatile for multi-industry use |

| Power Range | 100W–3000W adjustable | Scalable performance for varying tasks |

| Cooling System | Water-cooled | Ensures continuous operation without overheating |

| Certifications | CE, EPR Germany Packing | Compliance with EU safety and environmental standards |

| Safety Features | Interlocked guards, modular design | Operator protection and easy maintenance |

Adjustable power levels (100W–3000W) allow customization for specific material thicknesses or rust severity. Water-cooling flow rates can be optimized for high-temperature environments.

With the AKQ-1000, you can eliminate rust from machinery, automotive parts, or structural steel without damaging surfaces. Its fiber laser ensures spotless finishes for pre-welding, restoration, or maintenance projects.

| Parameter | Base Model (1000W) | Advanced Model (2000W) | Pro Model (3000W) |

|---|---|---|---|

| Power Output | 1000W | 2000W (+100%) | 3000W (+200%) |

| Beam Precision | ±0.1mm | ±0.05mm (+50%) | ±0.02mm (+80%) |

| Cooling Efficiency | 5L/min | 8L/min (+60%) | 12L/min (+140%) |

| Max Material Thickness | 5mm | 8mm (+60%) | 12mm (+140%) |

Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Power Output | Industrial plants, large-scale cleaning | Industry: 1000W (ISO 14919) ▲ Base: 2000W ▲ Advanced: 3000W (Max power for heavy-duty) | ▲ Base: 2x faster rust removal vs industry. ▲ Advanced: 3x faster for large surfaces. | Higher energy consumption; bulkier design for advanced models. |

| Cooling System | 24/7 factories, continuous operation | Industry: Air-cooled ▲ Our: Water-cooled (8hr continuous use, ISO 9001) | ▲ Base/Advanced: 40% longer runtime than air-cooled systems. | Requires water supply; maintenance for cooling lines. |

| Material Compatibility | Automotive, aerospace, construction | Industry: Metals ▲ Our: Metals/Stainless/Aluminum/Carbon Steel (ASTM A370) | ▲ Base/Advanced: Handles 4x more material types than industry standards. | May need parameter adjustments for each material type. |

| Laser Type | Precision electronics, delicate surfaces | Fiber Laser (1064nm wavelength, standard in industry) | High precision (±0.1mm accuracy) with minimal thermal damage. | Higher upfront cost vs CO₂ lasers. |

| Certifications | EU exports, regulated industries | Industry: CE ▲ Our: CE + EPR Germany (Compliance with EU and German standards) | ▲ Advanced: Meets stricter German environmental regulations. | Certification costs increase by 20% for EPR compliance. |

| Rust Removal Efficiency | Shipbuilding, heavy machinery maintenance | Industry: Basic rust removal ▲ Our: 99% rust removal (ASTM G15) | ▲ Advanced: Removes 99% rust in 1 cycle (vs 70% industry average). | Less effective on non-rust contaminants like oil or grease. |

⭐⭐⭐⭐⭐ James Peterson - Automotive Repair Workshop Owner

"Purchased the AccTek AKQ-1000 (Base Model, 1000W) in February 2025 to tackle rust on classic car frames. After 5 months of weekly use, I'm blown away by its precision and ease of operation. The digital controls made setup intuitive, even for someone with no prior laser experience. It removed decades of surface rust without warping thin steel—something sandblasting always ruined. The compact size fits perfectly in our small garage."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Müller - Maintenance Supervisor, Precision Engineering Plant

"We integrated the AKQ-1000 Pro Model (3000W) into our production line last November (2024) for pre-weld cleaning of carbon steel components. After 8 months of near-continuous operation, it’s reduced our surface prep time by over 60%. The water-cooling system keeps it stable during long shifts, and the ±0.02mm beam precision ensures flawless weld adhesion. CE and EPR Germany certifications were essential for compliance—no issues there."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Tran - DIY Metal Restorer

"I bought the 1500W version (custom-configured for rust removal) in April 2025 for restoring old motorcycle parts. Used it weekly for 4 months. The fiber laser is incredibly effective on aluminum and stainless steel—no more toxic chemicals or aggressive grinding. Only reason I didn’t give 5 stars? The water-cooling unit requires a dedicated reservoir, which takes up space in my shed. But the modular design makes maintenance easy. Highly recommend for hobbyists serious about restoration."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Sofia Ramirez - Lead Technician, Custom Auto Fabrication

"We’ve been using the AKQ-1000 Advanced Model (2000W) since January 2025 for both rust cleaning and precision welding on custom builds. The ability to switch between tasks seamlessly has streamlined our workflow. It handles everything from exhaust manifolds to chassis reinforcements. The safety interlocks give peace of mind in a busy shop, and the machine’s compact footprint was critical for our tight workspace. Customer service helped us configure the right power settings for aluminum vs. steel—huge plus."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Thomas Reed - Boatyard Maintenance Manager

"Saltwater corrosion is a constant battle. We got the Pro Model in June 2024 for removing rust from marine hardware and prop shafts. Now 7 months in, it’s performed flawlessly. The 99% rust removal efficiency claim is accurate—no more pitting or incomplete cleaning. It’s faster than abrasive blasting and doesn’t create hazardous dust. The stainless steel housing resists the salty environment, and the water-cooling system runs reliably even in summer heat. Worth every penny for marine industrial use."Purchase Date: June 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Fischer - Senior Laser Systems Engineer, Industrial Automation Institute

"The AccTek AKQ-1000 stands out in the mid-range industrial laser market due to its multi-material adaptability and water-cooled durability. Its fiber laser system offers superior absorption in metals like aluminum compared to CO₂ alternatives, making it ideal for modern fabrication shops. I recommend the Pro Model for facilities requiring high-throughput rust removal with minimal thermal distortion."

Mark Benson - Industrial Workflow Consultant

"After evaluating over 30 laser cleaning systems, I consistently recommend the AKQ-1000 series for its programmable automation and modular serviceability. The digital interface allows integration into smart manufacturing systems, and the ability to scale from 100W to 3000W ensures ROI across business sizes. It’s particularly effective for companies transitioning from manual surface prep to automated, eco-friendly processes."

Posted: 2 days ago

"Used it for the first time on a 1940s tractor frame—removed rust down to bare metal without damaging the base material. The precision is unmatched. Setup was simple thanks to the clear interface."

Posted: 1 week ago

"Paired the AKQ-1000 with our robotic arm for automated surface cleaning. The programmable controls made integration smooth. No downtime from overheating, even after 12-hour runs."

Posted: 3 weeks ago

"Perfect balance of power and size. Only suggestion: include a quick-reference guide for optimal settings per material. Otherwise, extremely satisfied with rust removal performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.